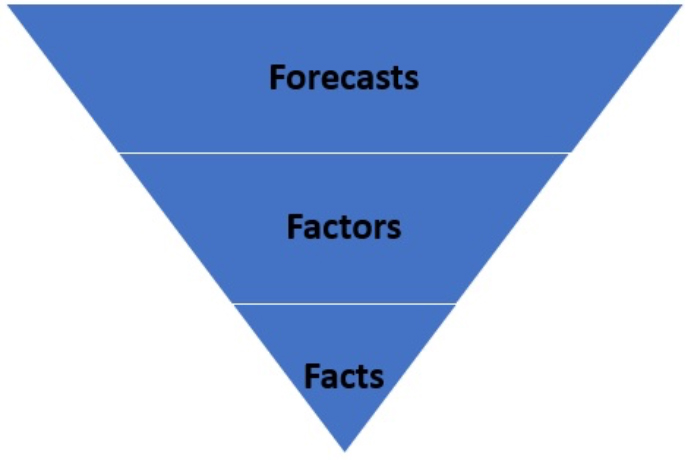

The Filtration Industry Can Improve EBITDA with the 3F Guide (Facts, Factors and Forecasts)

If the same amount of effort to prepare financial statements is also placed into gathering all the market facts, determining all the factors, and then making reliable forecasts, the benefit will far outweigh the costs.

In the last two decades major league baseball has incorporated the structured approach of facts, factors, and forecasts to the performance of the players, the competition and any fact or factor which can influence success.

The third base coach no longer just relies on his experience to signal a steal, but on mountains of facts and factors relative to the success forecasts. Facts involving the pitcher, catcher, and runner are tabulated and factors are created to guide the best decision.

The number of baseball club performance facts and factors can equal those in the financial statements.

Filter manufacturers can obtain similar benefits from comprehensive use of facts and factors.

There can be many thousands of relevant facts. It is essential that they be organized and updated. Considerable expertise is needed to develop the appropriate factors which in turn lead to actionable forecasts to cover each key niche.

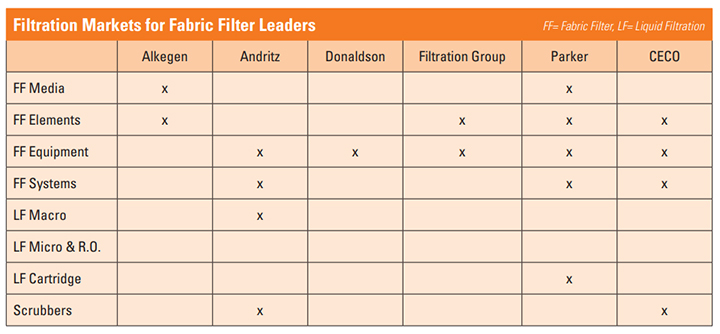

As an example, let’s focus on leaders in air pollution control fabric filters. How can they best use the 3F guide? The following companies are in the top 10 in some aspects of fabric filtration. The scope is cleanable dry filters used for air pollution control and process particle capture.

Fabric filters are not the leading product for any of these companies even though they are market leaders.

Donaldson and CECO are the only two on the list where fabric filters are more than 10% of sales. It is big for Parker but not compared to all the other products.

From a vertical perspective, none of the companies is complete starting with media and then up through systems.

None of the companies except Andritz is active in wet microfiltration. None of the companies is a top player in microfiltration and RO.

Two of the companies also supply scrubbers which compete with fabric filters in some cases and are used with them in others.

The conclusion is that all these companies see fabric filters as complementary rather than the core product. The first planning priority is to organize all the facts, factors and forecasts for the core products and then see how fabric filter initiatives will be attractive.

This question in revenue is what are the industry, geographic and process strengths for fabric filtration and how do they complement other products.

- Countries: the fabric filter market can be divided into 80 geographical segments including 72 countries and 8 sub regions.

- There are 15 major industry categories, one of which is waste to energy (WTE).

The WTE market can be used as an example of 3F. The facts include:

- Waste generation quantities in each country

- % of waste combusted in each country

- Regulations relative to disposal

- Local system designers

- International systems suppliers and operators

- Various removal technologies for particulate, VOCs, acid gases, and toxic metals

- Potential for valuable metal recovery

- Potential for CO2 capture and sequestration

- Integration with broad biomass combustion initiatives

Factors include:

- World political and economic developments

- Climate change impacts

- GDP growth and ability to fund waste disposal

- Changing perceptions about biomass and carbon negative aspects

- Changing ratio of dry versus wet scrubbers by country

- Increasingly stringent regulations for both particulate and gases

- Client challenges such as dealing with third world governments and international owner-operators

- Keeping up with technology developments

Thousands of facts need to be gathered and hundreds of thousands of factors applied to maximize EBITDFA from WTE.

At first glance only Andritz, Alkegen and Filtration Group should be extending major effort in this application. Only Andritz should clearly be extending maximum effort. The test should be if you cannot justify gathering all the facts and applying the factors then it is better not to halfheartedly pursue the market.

Andritz is an air pollution systems supplier with experience in WTE and with other biomass combustion systems.

With the Russian invasion of Ukraine, Europe is looking at biomass combustion as an alternative energy source. The 4000 MW Drax plant in the UK has switched to biomass and will be sequestering the CO2 in the North Sea. This will make this plant the largest carbon negative producer in the world and will offset a significant percentage of the UK CO2 emissions.

Alkegen and Filtration Group have developed fabric filter elements which are ceramic candles with embedded catalyst. Systems using these elements and direct sorbent injection can remove particulate VOCs, NOx, and acid gases.

Andritz also supplies scrubbers which can be utilized to recover valuable metals from the incineration exhausts.

A few international WTE BOO companies are on the one hand big potential customers and on the other potential competitors.

This listing of facts and factors applies to only one industry and to the equipment. Alkegen, Parker, and Filtration Group supply filter elements to end users and OEMS. Filter elements are replaced depending on the application from quarterly to every 5th year. Invaluable metal mining the filter is often a product recovery device with a positive ROI in just weeks.

So, the facts and factors for filter element producers are different than for equipment suppliers.

The organization of large numbers of facts and factors may seem daunting but as major league baseball has proven the benefits outweigh the costs.

1Air, Water, Energy Markets published by The McIlvaine Company