In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg: ken@filtnews.com

Most recent update: September 28, 2022

Metso Outotec to set up new filter plate factory in Mexico

Global mining engineering company Metso Outotec has announced plans to establish its first polymer filter plate production unit in Mexico. With this investment, Metso Outotec is responding to global market demand by increasing its capacity to deliver quality polymer filter plates for its mining customers’ filter presses.

The company is set to invest a total of around US$28.2 million to acquire the land and develop the production facilities by 2025. The construction work will begin as soon as the acquisition of the land and the planning of the facility have been completed, said the Finnish mining firm in its statement.

The construction of the new factory is expected to begin in 2023 and reach full capacity during 2025, following a gradual ramp-up. Once fully operational, the new factory is expected to employ around 60 skilled personnel, it added.

Source: www.mogroup.com

Freudenberg to showcase filtration media at WFC13

Freudenberg Performance Materials will showcase its high-performance filtration media solutions for the first time at the 13th World Filtration Congress (WFC13) which takes place in San Diego, California, USA from 6–8 October.

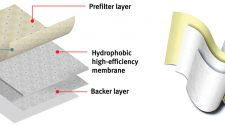

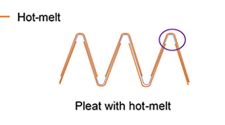

Among Freudenberg’s highlights will be Colback Plus, a unique solution for improved air quality. The pleatable medium has a built-in filtration capacity layer and can be used as a carrier in the manufacturing of cabin air, room air and HVAC filters. Colback Plus combines high performance characteristics such as low pressure drop and high pleat stiffness with a unique fine fiber technology.

Freudenberg Performance Materials offers filtration media and carrier materials in the form of roll goods for use in HVAC technology, pool & spa, reverse osmosis filters and biofiltration media as well as liquid filtration. Innovations include biocide and antimicrobial additives, spunlaid, drylaid, wetlaid, meltbown, activated carbon and microfilament technologies together with the relevant specific web bonding technologies and further finishing processes such as coating, impregnating or printing, tailored precisely to the needs and wishes of customers.

Source: www.freudenberg-pm.com

BYU students create new water filtration device for Pakistan

Working in Provo, Utah, a group of BYU engineering students created a new filtration device that is helping thousands of people across the world in Pakistan have access to cleaner, safer drinking water.

Elder Peter F. Meurs, a General Authority Seventy, was the lead manager for the water filtration project as he was serving as first counselor in the Asia Area Presidency.

“In talking to government leaders about the highest humanitarian priorities, leader after leader identified clean water as a very significant priority for the country,” Elder Meurs said in a BYU News release.

About 30% of diseases in Pakistan come from contaminated water — but those diseases are preventable.

Owen Tolley, a student on the BYU team, said they thought a lot about what they wanted to be able to fix like turbidity, coliforms including e coli, and arsenic — which is known to be found in high levels in certain regions.

“We thought a lot about what methods would 1) be most effective at treating the water 2) be robust and simple to use and maintain 3) be economical,” Tolley wrote in an email to the Church News.

They came up with a device that takes water through both microfiltration and ultrafiltration. Team member Bethany Parkinson said they took it to the duck pond south of BYU campus.

No more harmful bacteria remained in the BYU Botany Pond water. Tolley said the prototype gave them an idea of what was possible, and then they connected with a Pakistani company that was able to build and maintain the systems at a reasonable cost.

Elder Meurs ordered 15 water treatment devices, which were implemented immediately in the Asian country.

Source: byu.edu

Homemade air purifiers that trap COVID-19

A group of students from the University of Connecticut along with team members at UConn Health in Farmington built an air purifier out of furnace filters, a fan and tape. It’s called the Corsi-Rosenthal box, and it traps the COVID-19 virus inside.

“It captures fine particular matter in the air about as fine as a commercial filter,” said Marina Creed, APRN of UConn Health’s MS Center.

“We’ve found these are incredibly effective at lowering the levels of particles and these particles transmit infectious diseases like COVID and the flu in classrooms,” said Dr. Kristina Wagstrom from the UConn School of Engineering.

Creed and Dr. Wagstrom rallied experts from UConn Health and UConn in Storrs to recreate the Corsi-Rosenthal box.

Research shows it traps upwards of 90% of small particles from inside a room.

At around just $60 to make, hundreds of the boxes are in local schools like in Coventry and West Hartford, and even the White House.

With the success they’re seeing in classrooms, the goal is to get more of these homemade air purifiers throughout the state to help keep COVID numbers low.

Source: uconn.edu

Membrion secures DOE grant for novel manufacturing of desalination membranes

Seattle-based membrane startup Membrion has received a US$1.1 million grant from the United States Department of Energy (DOE), Advanced Manufacturing Office (AMO), through the Small Business Innovation Research (SBIR) program.

The Phase II Award will support a two-year project to develop, implement, and optimize a machine vision system to provide real time analytics of Membrion’s roll-to-roll ceramic desalination membrane production line.

A critical component of the DOE’s Water Security Grand Challenge is to address water security and alleviate water stress. Over the next ten years, nearly every US state will experience a water shortage, caused by climate-driven water shortages and dramatic increases in the demand for clean water. Membrion is on a mission to recycle water that was previously too challenging to reuse, using silica to create ceramic desalination membranes.

Source: www.membrion.com

ZwitterCo raises $33M for wastewater filter tech

ZwitterCo, a wastewater filter membrane manufacturer, announced it raised $33 million in Series A funding led by DCVC. The Boston-based company plans to use its new funds to expand the development and production of its zwitterionic membrane product.

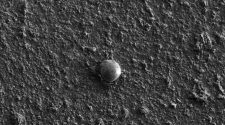

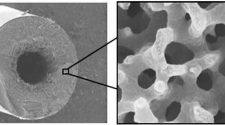

Photo courtesy ZwitterCo

ZwitterCo’s technology is a rugged polymeric membrane used for wastewater purification. The membrane is reportedly immune to “irreversible fouling,” unlike other water cleaning cycle membranes that degrade over time and need to be replaced. According to the company, its membranes perform as if they are new following each cleaning cycle, saving wastewater plants time and money in membrane replacement.

The ZwitterCo membrane is made of zwitterion, a special class of hydrophilic molecules that are highly attractive to water. The membrane uses patented zwitterionic copolymers that can self-assemble into hydrophilic channels, which let water pass through but trap anything else.

ZwitterCo’s technology can be used in a variety of applications and can repel thousands of times more organic compounds than traditional filters, according to the company. Currently, the company is working on building its suite of products and expanding its technological capabilities.

Source: www.zwitterco.com

Ohio Fabricators grows business, announces new products

Ohio Fabricators Company (OFCO), a leading manufacturer of stock and custom strainers, breathers, diffusers and screen assemblies for the filtration and fluid power industries, is reporting strong results despite many challenges in the overall business environment.

According to OFCO Chief Executive Officer Mike Shaw “we’ve been able to build our inventory of parts, during these tough times, allowing us to deliver finished products from our Coshocton, Ohio facility much faster than our competitors, while reducing our dependence on foreign-manufactured components.”

Sales Manager Mike Smith said, “we have two new products that we’ve had in development for a while.” These include our OS line of giant suction strainers with diameters up to 8.1” and flow rates up to 400 GPM. The other product is a screen developed specifically for the insect control business. Smith says that the first run of this product has already sold out with many more customers interested in it.

The OS strainer line is targeted to heavy industrial users such as oil and gas, steel production and pulp and paper mills. Oil and gas industries employ power units that push up to 400 gallons per minute (GPM) through their systems while the steel industry has equipment requiring up to 800 GPM flow rates. OFCO’s OS line is perfect for these applications.

Source: www.ohfab.com

NAFA announces 77 Clean Air Award Recipients for 2022

The National Air Filtration Association has announced its recipients of the Clean Air Awards for 2022. The Clean Air Award is presented each year to the building owners and managers who take steps to significantly improve the quality of their indoor air by increasing the level or efficiency of their HVAC air filtration system in 10 specific categories.

NAFA’s Executive Director, Emily Bardach, CAE, congratulated the award winners by saying, “The 2022 Clean Air Award program received an unprecedented number of submissions this year. The past few years have been a challenge for our members and their clients. Responding to the need for stricter indoor air quality specifications, the nominated facilities have all increased the level of indoor air cleanliness with filtration and improved system hygiene.”

Candidates are nominated for the award by NAFA members and must submit detailed and specific steps taken toward cleaning the indoor environment through “best air filtration practices” and system hygiene. A NAFA Certified Air Filter Specialist confirms these improvements. Nominees are judged by the NAFA Clean Air Award Committee, and each recipient receives a custom-designed award, building signage and recognition for their efforts.

Award-winning buildings must maintain IAQ diligence and submit inspection data each year to maintain the NAFA Clean Air Award.

Source: www.nafahq.org

American Air Filter Co., Inc. Acquires National Air Filter Service Co.

American Air Filter Co., Inc. (AAF International), a global leader of air filtration solutions for over 100 years, has acquired National Air Filter Service Company of New Jersey, USA, one of the oldest and largest full-service air filtration management companies in the United States.

“This is an exciting announcement for us that we believe will yield important benefits for our customers and our vendors while ensuring the continuity of our business and relationships,” said Don Borghoff, President and Owner of National Air Filter Service Company of New Jersey. “This acquisition symbolizes our intention to deliver more value to our customers while providing them with the same great service they have come to expect,” Borghoff added. This change in ownership was effective August 29, 2022.

Source: www.aafintl.com

Hengst Filtration to acquire Linter Group in Brazil

Germany’s Hengst Filtration is acquiring Linter Group, a Brazilian company that manufactures air filters and air filtration equipment. Linter has been supplying the South American market with filtration solutions since 1995 and employs around 100 people and is based in São Paulo. Linter products can be found in the food industry, in laboratory and pharmaceutical facilities and in commercial air conditioning and ventilation technology.

“With this acquisition, we not only underline our claim to leadership in industrial filtration, but can also further expand and strengthen our vision “purifying our planet” in the South American market with the filter applications of the Linter Group,” said Christopher Heine, CEO of Hengst SE. “Linter has impressed us with its strong growth in recent years and we are pleased to be able to acquire one of the three leading companies in the field of industrial air filtration in Brazil for the Hengst Group.”

Hengst has been operating in Brazil for over 20 years with a sales office in São Paulo and a production site in Joinville.

The Linter acquisition is expected to close in the fourth quarter 2022. The owners will remain with the company after the sale and will closely accompany the integration of Linter into the Hengst Group.

Hengst continues to focus on growth and the expansion in filtration solutions for industrial and indoor air applications, having acquired Nordic Air Filtration in 2016, Delbag in 2018 and the hydraulic filtration business of Bosch Rexroth last year.

Source: www.hengst.com

Pall breaks ground for new facility in Singapore

Pall Corp. a global leader within the filtration and separation industry, recently held a groundbreaking ceremony for its new $100 million state-of-the-art manufacturing facility in Singapore to meet unprecedented global semiconductor demand. When fully operational, the new facility is expected to more than double Pall’s current production capacity and strengthen its position in Singapore as a regional and global hub for customers in the Asia Pacific region.

“We expect the APAC region will soon outstrip other markets to become an anchor in the global semiconductor industry. Today, APAC accounts for most of the global semiconductor market. With large-scale investments in Singapore, along with Tsukuba, Japan, Pall is well positioned to offer substantial expertise in advanced node solutions and a vast footprint of technologies to serve the growing demands of chip manufacturers in the region,” said Naresh Narasimhan, president of Pall Corp.

The facility will occupy a seven-acre campus that will include more than 18 000 m2 of manufacturing and office space. High-volume manufacturing (HVM) and research and development capabilities are planned to be completed between late 2023 and early 2024, creating up to 300 new jobs.

“The US$100 million investment demonstrates Pall’s commitment to help customers meet extremely challenging defect reduction goals amidst a global chip shortage crisis as new technologies, such as 5G, artificial intelligence and automation, evolve and continue to drive transformation,” added Narasimhan.

Source: www.pall.com

LG unveils ‘table-type’ air purifier

LG Electronics (LG) is presenting its new air purifier, the PuriCare Objet Collection Aero Furniture, at IFA 2022. The follow up to the acclaimed PuriCare AeroTower revealed at CES earlier this year, the new table-type model blurs the line between beautiful furniture and advanced air purifier, offering a design that can be tailored to meet individual preferences, 360-degree air purification, and user-friendly features.

The compact LG Aero Furniture has a relatively small size that makes it perfect for smaller spaces, such as a single bedroom, study or studio, while users can choose the color of the unit’s base (Crème Rose, Crème Yellow to Crème Grey) and the shape of its table-top (Round or Track) to suit their personal tastes or match their home décor.

The smooth upper surface of LG’s innovative, new product provides a useful place for storing household items or displaying decorative objects. It also integrates convenient controls on its underside for powering the device on/off, and for managing its airflow modes and mood lighting features. Subtly positioned near the edge of the table-top, and flush with its surface, is a series of small indicators denoting Wi-Fi connectivity, air quality, air flow strength and upgrade status.

What’s more, the new Aero Furniture presents an array of thoughtful features for a more personalized user experience. Users can conveniently charge their smartphones and wireless earbuds via the table-top’s built-in wireless charger and create a pleasing atmosphere with the mood lighting feature. Providing eight different colors to choose from, Aero Furniture’s mood lighting can be easily controlled using the LG ThinQ app. Furthermore, LG’s unique air purifier is designed with sustainability in mind, incorporating components fabricated from reusable plastic harvested from old appliances and electronics products, and shipping in packaging made from reusable materials.

Source: www.lg.com

Grundfos closes business in Russia and Belarus

Danish company Grundfos paused its operations in Russia and Belarus earlier this year, and since then, the pump company has been winding down its activities including reducing staff numbers and settling relationships with customers, vendors, and other partners, while assessing the situation related to the war in Ukraine. With no signs that the situation will change and in line with its values, Grundfos will now fully close in Russia and Belarus.

A significant one-off cost of DKK851 million related to the closing will be reported in Grundfos’ half-year results.

For now, this will mark the end of Grundfos’ 23 year-presence in Russia. Grundfos said they would like to thank their colleagues for their dedication, and their customers and partners for their strong support and collaboration over the years.

Source: www.grundfos.com