Solutions for air, oil & gas, pool & spa, reverse-osmosis and ultrafiltration

For 40 years, Polyset has been a leading custom formulator of two-component Polyurethane Adhesive, Elastomer, and Foam Systems for the industrial and commercial filtration industries. We pride ourselves on our in-depth understanding of specific filter processing and performance requirements, batch-to-batch consistency, competitive pricing, and customer service. Our polyurethane materials are available in soft-to-rigid durometers, low-viscosity-to-thixotropic consistencies, with formulated systems available for high-temperature resistance, high-tear strength, and with excellent adhesion to a variety of substrates and filter media.

Air

Our custom formulated polyurethane adhesives also meet strict requirements for High Efficiency Particulate Air (HEPA) filters, including formulations with low-outgassing and those capable of meeting specific requirements of the various certification agencies. Our polyurethane materials can be found in HEPA filters for the nuclear, pharmaceutical, and semiconductor industries.

Performance benefits:

- Flow-through to thixotropic viscosity characteristics

- Flame retardancy

- FDA-compliant raw materials

- Ultra-low outgassing

Oil & Gas

Our range of polyurethane/modified epoxy adhesives are formulated to possess excellent physical properties, along with high temperature and chemical resistance to gasoline, hydraulic fluids and oils.

Performance benefits:

- High temperature resistance

- Excellent chemical resistance (fuels, oils, and solvents)

- Superior adhesion to metal and plastic

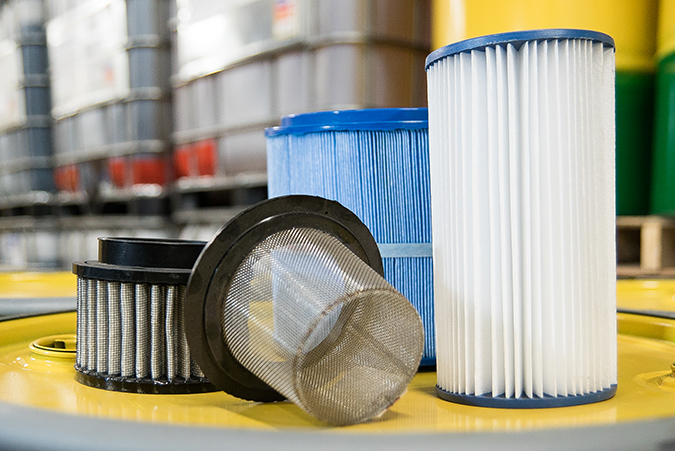

Pool & Spa

Our polyurethane molded end cap formulations for the pool and spa industry are resistant to chlorine and other common pool/spa chemicals while also withstanding the growth of mold, mildew, and bacteria. These cast polyurethanes can be formulated in a range of colors and durometers to meet the specific pool/spa filter cartridge assembly requirements.

Performance benefits:

- High tear strength properties

- Excellent chemical resistance

- No wicking

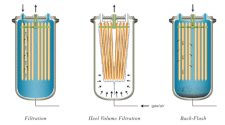

Reverse Osmosis & Ultrafiltration

Our custom-formulated polyurethane adhesives bond well to specialized membranes in separation process filters and can be formulated to fit different assembly scenarios. The polyurethane’s chemical composition has a high degree of hydrolysis resistance and minimal hardness loss in water at elevated temperatures (185 F).

Performance benefits:

- Custom formulations with raw materials suitable for NSF/FDA applications

- Minimal blistering

- High membrane penetration

- Excellent adhesion to various membranes and substrates

This content is sponsored by Polyset.