End-Use Markets

Clean Air… A Right or Delight?

Deciphering the Decision-Making Process in the Hindsight of Covid-19 Pandemic to Discover IAQ and Clean Air Foresight to Design Cities for Air Quality It is challenging to advance the cause …

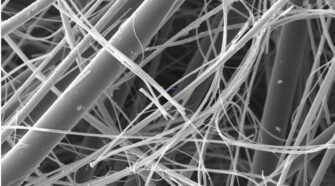

Green or Durable? Automotive & Aerospace Fibers in Filtration

Fibers are main raw materials for making filter media in aerospace and automotive filtration applications. They can be chosen from a wide range of materials, including celluloses, thermoplastics, and glass …

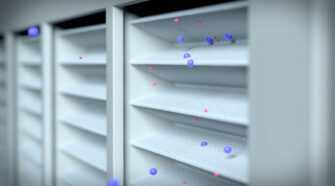

Breathing Easy: A Breakthrough Solution for Indoor Air Quality

North Carolina State University Researchers Develop an Air Filtration Technology that Catches and Kills Pathogens with up to 99.9% Efficiency While the need for effective air filtration technologies has long …

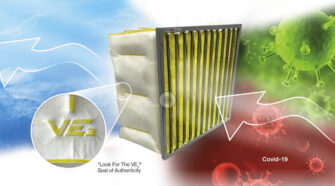

Fiber Bond’s Enhanced VE3® Technology Inactivates Influenza, SARS-CoV-2 in HVAC Filtration Systems

Air Filtration Pioneer Unveils Newest Innovation to Better Protect the Air We Share Fiber Bond, a pioneer in air filtration solutions, is building on its earlier success in inactivating the …

Spain A New Global Water Leader

From a Point of Distress, the Country is Being Thrust Into Global “Wicked Water Problem” Stage One of my favorite quotes is: “The future is already here – it’s just …