With COVID-19 having an impact worldwide, International Filtration News is tracking stories relevant to the filtration industry. Filtration media for facemasks and respirators are at the forefront of the COVID-19 response effort, and meeting the demand for these types of filter media is proving to be a challenge. As manufacturers of filter media and others struggle to find ways to meet the need in the face of the growing COVID-19 pandemic, news stories are breaking quickly. Here we will post relevant news stories on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Matt Migliore at mmigliore@inda.media.

Most recent update: February 14, 2022

Nelson Labs announces verification program for facemasks and respirators

Nelson Labs, a leading global provider of laboratory testing and advisory services, has launched the Nelson Labs Mark, a verification program for product testing that authenticates test reports and provides data on product performance. The new offering is designed to empower consumers to make informed decisions when purchasing facemasks and respirators, as well as providing credible manufacturers with the means to differentiate their products from others on the market.

Amidst a rise in fraudulent products and the ongoing COVID-19 pandemic, Nelson Labs anticipates the program will become a valuable tool for hospitals, municipalities, and commercial buyers, along with private consumers. According to Nelson Labs, the Mark will begin with testing verification for masks and respirators but will expand to other products as the market requires.

“With varying regulatory requirements and amended qualifications during COVID-19, it is difficult for today’s consumers to discern legitimate products from those that have not been adequately tested,” said Jeffery R. Nelson, chairman, Nelson Labs. “The Nelson Labs Mark addresses this critical need for increased transparency by providing objective, verifiable performance data from our world-class laboratories.”

To further increase consumer confidence, the Nelson Labs Mark includes two-factor authentication for consumers to easily confirm the legitimacy of a product’s testing. The company will allow manufacturers participating in the Nelson Labs Mark program, whose products have undergone testing at Nelson Labs, to use the Nelson Labs Tested™ or Nelson Labs Verified™ mark on applicable product packaging and marketing, along with a corresponding web listing that includes detailed test reports outlining the performance of that product.

For more details on the program, visit nelsonlabs.com/get-verified.

Source: nelsonlabs.com

Texas Tech researchers author study using new standardized mask filtration testing to evaluate effectiveness of alternative facial coverings

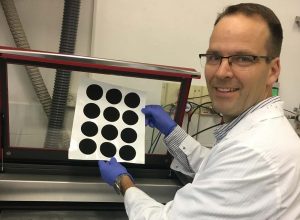

Seshadri Ramkumar, a professor of chemical countermeasures and advanced materials in Texas Tech University’s Department of Environmental Toxicology, has co-authored a study utilizing standardized methods to evaluate common household fabrics as alternative materials for barrier face coverings. Olukayode James Ayodeji, a Ph.D. candidate in the Department of Environmental Toxicology, conducted the standardized tests measuring the filtration efficiency (FE) of different facial coverings.

Using mask filtration testing standards developed by the American Society for Testing and Materials (ASTM), Ramkumar and his team compared the performance of popular ready-made facial coverings, such as bandanas and neck gaiters, to alternative household materials including denim, cotton shirts, bedding and towels. Both categories of materials were measured against R95 masks, which offer the highest level of protection against viral particles.

While a material’s ability to filter out viral particles is paramount, breathability is an equally important consideration, Ramkumar said. Unfortunately, testing revealed an inverse relationship between filtration efficiency (FE) and breathability – for instance, while denim showed the highest FE, it also had the lowest breathability of all the household fabrics, rendering it unsuitable for facemask production. Ramkumar and his team took both parameters of FE and breathability into equal account when evaluating a material’s overall performance.

According to their study, the most effective ready-made facial coverings on the market are Velcro masks with carbon filters and surgical masks, while the least effective are fashion facemasks, single-layer face coverings, neck gaiters and bandanas.

The highest-performing household materials were thick cotton shirts and towels, indicating that multi-layered cotton facial coverings with proper fit are the most effective homemade mask alternative because they offer a measure of protection against viral particles without compromising breathability.

A combinatorial approach involving both a facial covering and a surgical mask with good fit would offer the wearer better protection against particle inhalation, Ramkumar said.

Ramkumar co-authored the paper, “Particle-Size-Dependent Filtration Efficiency, Breathability, and Flow Resistance of Face Coverings and Common Household Fabrics Used for Face Masks During the COVID-19 Pandemic,” alongside Texas Tech graduate students Olukayode James Ayodeji and Terrell A. Hillard, with the support of Texas Tech graduate student Mirza Khyum. The study was published in Volume 16 of the International Journal of Environmental Research earlier this month.

Source: tiehh.ttu.edu

Filtration devices could make dentist appointments safer during the COVID-19 pandemic

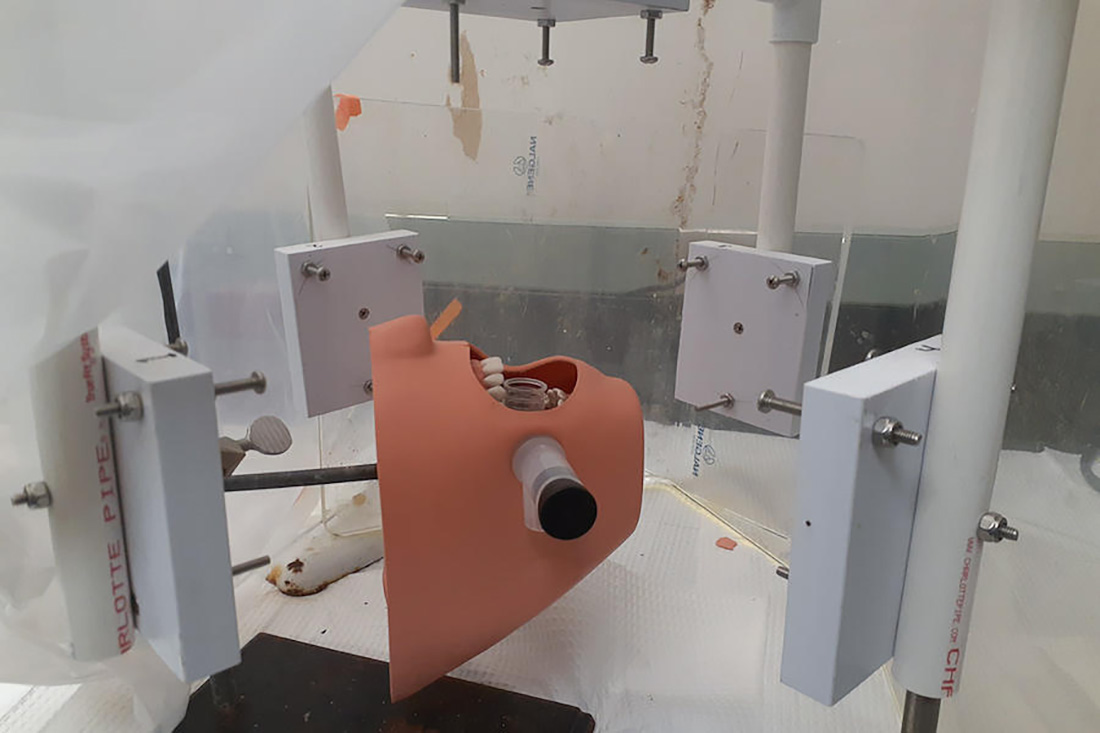

In a new study using 3D holographic imaging, University of Minnesota Twin Cities researchers tested the effectiveness of three filtration devices that can mitigate the spread of aerosols during ultrasonic scaling, a common dental cleaning procedure. The findings could increase health safety in dental offices during the COVID-19 pandemic.

The researchers found that two of the devices—a high-volume evacuator and an extraoral local extractor—were very successful at reducing aerosol spread. This is one of the first studies to use advanced engineering imaging techniques to map the size, distribution, and mitigation of aerosols in dental offices.

The paper was published recently in the Journal of the American Dental Association, a peer-reviewed scientific publication from the world’s largest dental organization.

The University of Minnesota research team was led by College of Science and Engineering Professor David Pui and Associate Professor Jiarong Hong in the Department of Mechanical Engineering, with help from Professor Paul Olin, the Associate Dean of Clinical Affairs in the University’s School of Dentistry.

Read the full story: https://twin-cities.umn.edu/news-events/filtration-devices-could-make-dentist-appointments-safer-during-covid-19-pandemic

Source: twin-cities.umn.edu

Test results show ZENGuard coated facemasks provide 99.99% bacteria and virus filtration efficiency

Zen Graphene Solutions Ltd., a Canadian nanotechnology company focused on healthcare solutions, announced test results for bacterial filtration efficiency (BFE) and viral filtration efficiency (VFE) of its ZENGuard-enhanced surgical masks. The ZENGuard coated masks removed 98.9% more bacteria and 97.8% more virus particles compared to a typical ASTM level 3, 3-ply uncoated mask. With BFE and VFE levels over 99.99%.

- Testing was completed by GAP EnviroMicrobial Services Ltd., an ISO/IEC 17025:2005 compliant and Canadian Association for Laboratory Accreditation (CALA) certified testing facility

- A ZENGuard-enhanced mask and a leading ASTM level 3, 3-ply mask were exposed to S. aureus for BFE testing and MS2 Bacteriophage for VFE testing

- ZENGuard-enhanced mask removed 98.9% more bacteria and 97.8% more viruses in a head-to-head comparison with a leading ASTM level 3 mask

Source: zengraphene.com

US FDA updates enforcement policy for facemasks, respirators and related PPE to ensure availability

The U.S. Food and Drug Administration issued a revised guidance, Enforcement Policy for Face Masks, Barrier Face Coverings, Face Shields, Surgical Masks, and Respirators During the Coronavirus Disease (COVID-19) Public Health Emergency (Revised), to expand the availability of face masks, barrier face coverings and face shields for the general public, including health care personnel, as well as surgical masks and particulate filtering facepiece respirators (FFRs) (including N95 respirators) for health care personnel for the duration of the COVID-19 public health emergency.

This policy is intended to remain in effect only for the duration of the public health emergency related to COVID-19 declared by the Secretary of Health and Human Services (HHS) on January 31, 2020, effective January 27, 2020, including any renewals made by the HHS Secretary in accordance with section 319(a)(2) of the Public Health Service Act (PHS Act) (42 U.S.C. 247d(a)(2)).

Given this public health emergency, and as discussed in the Notice in the Federal Register of March 25, 2020, titled “Process for Making Available Guidance Documents Related to Coronavirus Disease 2019,” available at https://www.govinfo.gov/content/pkg/FR-2020-03-25/pdf/2020-06222.pdf, this guidance is being implemented without prior public comment because FDA has determined that prior public participation for this guidance is not feasible or appropriate (see section 701(h)(1)(C) of the Federal Food, Drug, and Cosmetic Act (FD&C Act) (21 U.S.C. 371(h)(1)(C)) and 21 CFR 10.115(g)(2)). This guidance document is being implemented immediately, but it remains subject to comment in accordance with the Agency’s good guidance practices.

Read the full guidance: https://www.fda.gov/media/136449/download

Source: https://www.fda.gov/

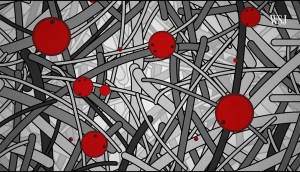

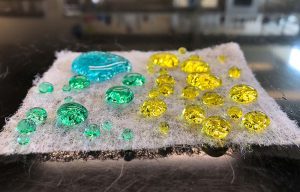

New research shows the interaction of water aerosol with nanofiber mesh facemask material

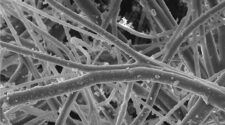

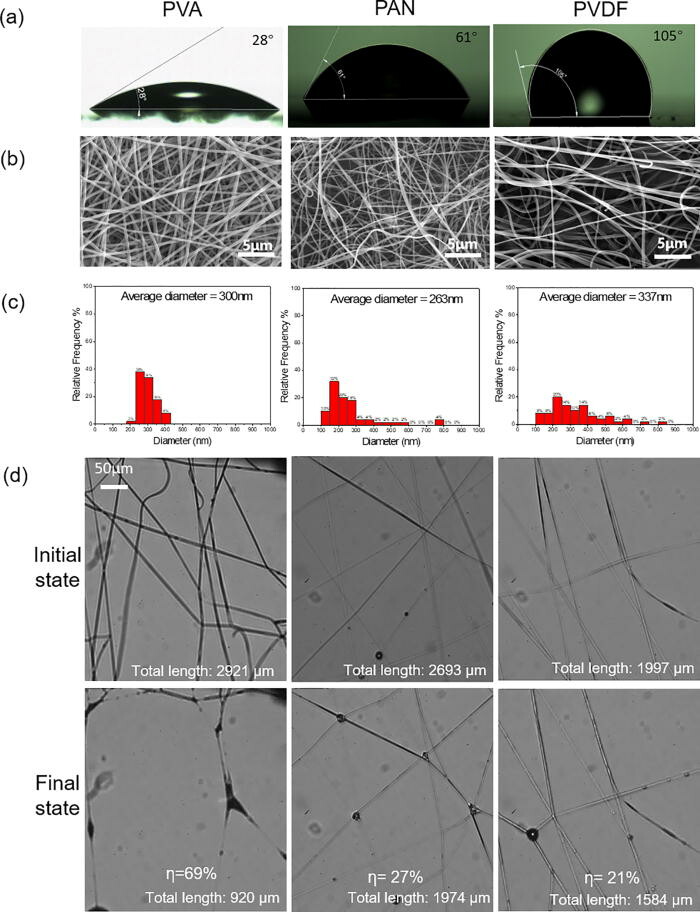

Facemasks made with nanofibers have drawn increasingly more attention because of their higher filtration efficiency, better comfort, and lower pressure drop. However, the interactions and consequences of the nanofibers and microwater droplets remain unclear.

New research published in the journal Physics of Fluids shows the evolution of fibers made of polymers with different contact angles, diameters, and mesh sizes under water aerosol exposure is systematically visualized. The images show that capillarity is very strong compared with the elasticity of the nanofiber. The nanofibers coalesce irreversibly during the droplet capture stage as well as the subsequent liquid evaporation stage. The fiber coalescence significantly reduces the effective fiber length for capturing aerosols. The nanofiber mesh that undergoes multiple droplet capture/evaporation cycles exhibits a fiber coalescing fraction of 40%–58%. The hydrophobic and orthogonally woven fibers can reduce the capillary forces and decrease the fiber coalescing fraction.

This finding is expected to assist the proper design, fabrication, and use of face masks with nanofibers. It also provides direct visual evidence on the necessity to replace face masks frequently, especially in cold environments.

Read the full story: https://aip.scitation.org/doi/full/10.1063/5.0061847

Source: https://aip.scitation.org/journal/phf

NCTO welcomes Senate passage of U.S. infrastructure bill, funding to bolster domestic PPE supply

The National Council of Textile Organizations (NCTO), which represents U.S. textile manufacturers from fiber through finished products, issued a statement welcoming Senate passage of a bipartisan infrastructure bill that will provide billions of dollars in new spending with the aim of revitalizing the nation’s roads, bridges and railways and help reconstitute a domestic supply chain for personal protective equipment (PPE).

“We commend the Senate for passing the bipartisan infrastructure bill, which will provide critical resources for our nation’s aging infrastructure and at the same time help incentivize the reshoring of personal protective equipment (PPE) production, an important priority of the U.S. textile industry,” said NCTO president and CEO Kim Glas.

NCTO worked with congressional allies to include a version of the Make PPE in America Act, legislation co-sponsored by Senator Rob Portman (R-OH) and Senator Gary Peters (D-MI), in the infrastructure legislative package. The bill ensures all PPE purchased by the Departments of Homeland Security, Health and Human Services and Veterans Affairs are Berry Amendment-compliant; guarantees long-term contracts (a minimum of two years) to U.S. manufacturers; and creates a tiered preference for PPE made in the Western Hemisphere by our free trade partners using U.S. components, after domestic manufacturing capacity has been maximized.

“We sincerely thank Senator Portman and Senator Peters for working to include their Make PPE in America Act in the infrastructure bill,” Glas said. “This bill will help onshore critical production of personal protective equipment (PPE) by guaranteeing long-term contracts for domestically produced PPE and ensuring that taxpayer dollars are utilized to bolster the federal purchase of American-made PPE.”

Source: ncto.org

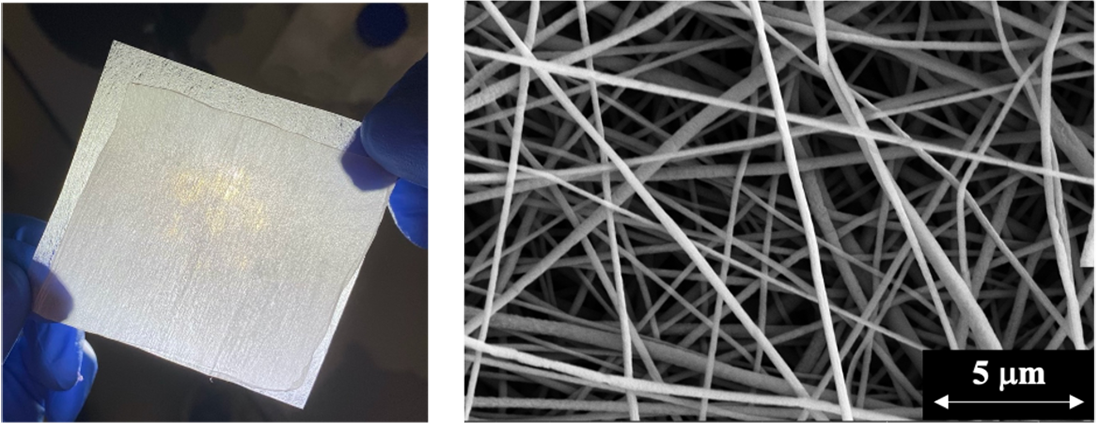

Polymer nanothread filter captures 99.9% of coronavirus aerosols in experiment

A filter made from polymer nanothreads captured 99.9% of coronavirus aerosols in an experiment.

“Our work is the first study to use coronavirus aerosols for evaluating filtration efficiency of facemasks and air filters,” said corresponding author Yun Shen, a UC Riverside assistant professor of chemical and environmental engineering. “Previous studies have used surrogates of saline solution, polystyrene beads, and bacteriophages — a group of viruses that infect bacteria.”

The study, led by engineers at UC Riverside and The George Washington University, compared the effectiveness of surgical and cotton masks, a neck gaiter, and electrospun nanofiber membranes at removing coronavirus aerosols to prevent airborne transmission. The cotton mask and neck gaiter only removed about 45%-73% of the aerosols. The surgical mask did much better, removing 98% of coronavirus aerosols. But the nanofiber filter removed almost all of the coronavirus aerosols.

Shen and George Washington University colleague Danmeng Shuai produced a nanofiber filter by sending a high electrical voltage through a drop of liquid polyvinylidene fluoride to spin threads about 300 nanometers in diameter — about 167 times thinner than a human hair. The process created pores only a couple of micrometers in diameter on the nanofiber’s surfaces, which helped them capture 99.9% of coronavirus aerosols.

The production technique, known as electrospinning, is cost effective and could be used to mass produce nanofiber filters for personal protective equipment and air filtration systems. Electrospinning also leaves the nanofibers with an electrostatic charge that enhances their ability to capture aerosols, and their high porosity makes it easier to breathe wearing electrospun nanofiber filters.

Read the full story: https://news.ucr.edu/articles/2021/05/17/nanofiber-filter-captures-almost-100-coronavirus-aerosols

Source: ucr.edu

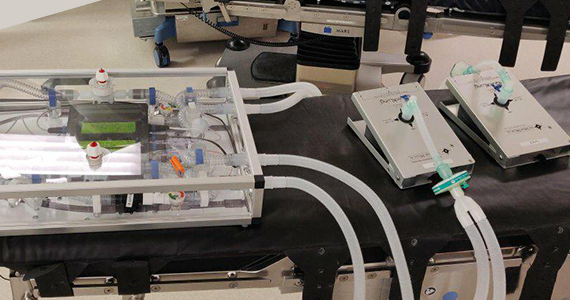

Meissner wins $13.4 million contract from BARDA to increase production critical to COVID-19 vaccine

Meissner Filtration Products announced the award of a $13.4 million contract from the Biomedical Advanced Research and development Authority (BARDA), part of the office of the Assistant Secretary for Preparedness and Response (ASPR) at the U.S. Department of Health and Human Services (DHHS), to facilitate expedited expansion of their production capacity for products critical to COVID-19 vaccine and therapeutics manufacturing.

“Meissner has experienced substantial demand for our products associated with federally funded vaccine and therapeutics manufacturing efforts,” stated Christopher Meissner, CEO of Meissner Filtration Products. “It has been incredibly fulfilling for our organization to be able to make a direct impact fighting this pandemic and this contract serves to amplify and accelerate those efforts.”

Meissner will be expanding its Camarillo, California, manufacturing campus by making a significant investment alongside the BARDA award to include additional cleanroom manufacturing space, implementing advanced inventory management systems and adding support areas to augment capacity.

“While we have seen increased demand on the basis of COVID-19 vaccines and therapeutics, our products are also a key piece in the development and manufacture of other lifesaving medicines so it’s critical that we able to support all of our customers through this period and in the future,” said Max Blomberg, Executive Director of Operations. “This expansion, which will provide a substantial capacity augmentation for our Camarillo campus, is just the latest in our continuing work to ensure we scale with our clients’ needs.”

This project has been funded in part with federal funds from the BARDA, ASPR, DHHS, under Contract No. 75A50121C00028.

Source: meissner.com

ASHRAE Epidemic Task Force releases ‘unequivocal statement’ on airborne transmission of SARS-CoV-2 in buildings

ASHRAE has released the following statement:

“Airborne transmission of SARS-CoV-2 is significant and should be controlled. Changes to building operations, including the operation of heating, ventilating, and air-conditioning systems, can reduce airborne exposures.”

It replaces the April 2020 statement that said airborne transmission was “sufficiently likely” that airborne precautions should be taken. At that time both, the World Health Organization (WHO) and the Centers for Diseases Control (CDC), contended that transmission of SARS-CoV2 was by droplet and fomite modes, not airborne. Subsequently, both have acknowledged the risk of airborne transmission indoors.

“This may seem like a small step, but we feel it is important to leave no doubt about our position, given the muted support for ventilation and filtration as important tools in the effort to stop the pandemic, from some organizations that should be leading more strongly,” said William P. Bahnfleth, Ph.D., P.E., ASHRAE Epidemic Task Force chair.

The ASHRAE Epidemic Task Force has been developing and disseminating guidance for the control of airborne transmission of SARS-CoV-2 since its formation in March 2020.

“ASHRAE volunteers have played a huge role in evaluating evidence and developing detailed guidance to improve indoor environmental quality,” said Bahnfleth. “The public, globally, is benefitting from the volunteer efforts of some of the most knowledgeable scientists and engineers in our field and this updated guidance is proof of it.”

To view the complete airborne transmission statement and other COVID-19 resources, visit ashrae.org/COVID-19. Questions specific to Epidemic Task Force guidance can be emailed to covid-19@ashrae.org

Source: ashrae.org

Researchers employ copper foam to filter microbes in facemasks and air filtration systems

During the COVID-19 pandemic, people have grown accustomed to wearing facemasks, but many coverings are fragile and not easily disinfected. According to research published in ACS Nano Letters, Georgetown University Department of Physics professor Kai Liu and his group of researchers have transformed copper nanowires into metal foams that could be used in facemasks and air filtration systems, which are more durable and have the potential to effectively filter out microbes.

“When a person with a respiratory infection, such as COVID-19, coughs or sneezes, they release small droplets and aerosolized particles into the air,” said graduate student James Malloy (C’22), first author of the study, “Minuscule particles can stay airborne for hours, so materials that can trap these tiny particles are ideal for use in face masks and air filters. The foams filter efficiently and can be easily decontaminated, reused repeatedly, and recycled.”

Though current filtration systems such as those in N95 masks are helpful in reducing the spread of COVID-19, the materials they are made with contain some drawbacks.

Fiberglass, carbon nanotubes and polypropylene fibers are not durable enough to undergo repeated decontamination procedures and some further rely on electrostatics that precludes washing, which leads to large amounts of waste from single-time use.

Liu’s team recently developed metallic foams with microscopic pores that are stronger and more resistant to deformation, solvents and high temperatures and pressures. As such, they wanted to test copper foams to see if they could effectively remove submicron-sized aerosols while also being durable enough to be decontaminated and reused.

Their most effective material was 2.5 millimeters thick and trapped 97% of deep submicron aerosolized salt particles, which are commonly used in facemask tests.

Read the full story: https://college.georgetown.edu/news-story/research-by-physics-professor-shows-copper-foam-could-be-highly-efficient-durable-filter-for-reusable-masks-and-air-cleaners/

Source: https://www.georgetown.edu/

Biden awards contracts for up to 22.2 million U.S. made facemasks

The National Council of Textile Organizations (NCTO) reported that the Biden Administration has awarded two contracts to Parkdale Mills and Ferrara Manufacturing Inc., as part of U.S. President Joe Biden’s pledge to procure millions of domestically made facemasks for community health centers, food pantries and soup kitchens across the country.

North Carolina headquartered Parkdale Mills, the nation’s largest cotton yarn spinner, has partnered with Ferrara Manufacturing, a tailored clothing company based in New York City’s garment center whose workforce is union represented by Workers United/SEIU, to manufacture over 17 million reusable masks.

The government said it could purchase up to a maximum of 22.2 million masks under the two contracts announced today. The masks will be Berry compliant, and thus 100% U.S.-made.

Ferrara Manufacturing and Parkdale Mills will contract with additional U.S. companies across the manufacturing supply chain, employing nearly 5,000 American workers as a result of these awards. Parkdale will be utilizing yarn from their facilities in NC, VA, and GA and Ferrara will deploy their cut and sew operations in New York City.

Source: ncto.org

Camfil to present webinar on managing virus threats with air filtration

On Thursday, April 8, Camfil will present a free webinar on how effective air filtration can help businesses, industrial facilities, healthcare facilities and public buildings mitigate virus infection spread. The virtual presentation will take place at 1:00pm EST.

The webinar will be led by Camfil’s Healthcare Segment manager, Kyle Petersen. With overall responsibility for providing the most compliant indoor air quality solutions to protect patients, visitors, and healthcare personnel in hospitals and other healthcare facilities, Mr. Petersen’s prior experience managing Camfil’s National Accounts Program has exposed him to a broad spectrum of air filtration in a variety of industry segments.

Key topics to be covered include:

- Air filter materials and configuration, and how they impact the ability of filters to mitigate virus risk

- Current scientific knowledge of the transfer dynamics of SARS-CoV-2 and other viruses

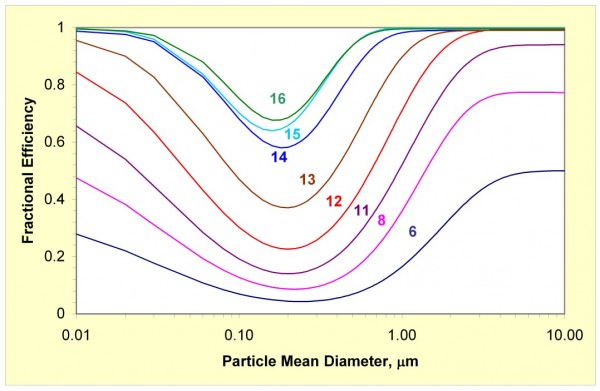

- The effectiveness of capture efficiencies at different MERV values

- The importance of MERV-A values in air filter choice

- Discussion of HEPA air filters and in-room air cleaners and air purifiers

Register for the webinar here.

Source: camfil.com

Ahlstrom-Munksjö, Virgis Filter S.P.A & Webasto partner to protect indoor environments from COVID-19

Ahlstrom-Munksjö has partnered with Italian filter producer Virgis S.P.A for the distribution of a HEPA filtration solution produced by Webasto, which is designed to make indoor environments safer against COVID-19 as well as other viral and bacterial organisms.

The HEPA devices, HFT300 and HFT600, were launched in Europe in 2020 to meet the demand for increased protection in vehicles and buildings. The main purpose of these filter devices is to protect the passengers and the operators in emergency vehicles, school buses and public transportation vehicles. The first units were primarily installed in ambulances in Germany and the U.S., as well as in public buses in the Netherlands and school buses in the U.S. Now the technology is being applied to offices, restaurants and museums.

The spread of COVID-19 and the consequent increase in the global demand for protective materials required many companies to rapidly adapt, leverage their expertise and innovate. Ahlstrom-Munksjö used its long-term experience and leadership in the manufacture of filters to develop a suitable media for HEPA H14, manufactured in a compact cartridge, which represents the core of the Webasto device.

The new HFT 300 and HFT 600 devices combine two main features to reduce viral loads in ambient air. They offer an extremely high virus removal efficiency thanks to HEPA H14 filters, and also generate very high air volume flow for the rapid and complete filtration of the air on an ongoing basis.

The HFT 300 and HFT 600 devices are specifically designed to filter the air, removing 99.995% of particulates corresponding to SARS/COVID-19 virus sizes (0.1 micrometers) and effectively reducing the risk of infection. Ultra-compact and light, these devices can be installed in less than 30 minutes.

The device complies with the International HEPA Filter standards WHO/CDC/ECDC, and is compliant with European Medical Device Directive CE 47/2007.

For more about HFT 300 and HFT 600 units from Webasto: https://www.webasto-comfort.com/int/content/air-filtration-system/

You can read more about HEPA filter from Ahlstrom-Munksjö: https://www.ahlstrom-munksjo.com/products/filter-media/air-filtration-for-industrial/high-efficiency-and-hvac/

Source: ahlstrom-munksjo.com

Nanocoating technology professes to stop SARS-CoV-2 in HVAC systems

A new nanocoating from Curran Biotech, based in Houston, Texas, professes to effectively and cheaply stop the spread and lingering impacts of the SARS-CoV-2 virus when applied to the filter fabrics in common HVAC (heating, ventilation and air conditioning) systems.

Curran’s Capture Coating permanently bonds to the porous materials within a filter, stopping viruses, bacteria and fungi dead, while not impacting airflow or breathability.

With the emergence of the worldwide pandemic, a new approach to protecting buildings and inside air from the transmission of contagions has been required, and the hydrophobic nanocoating was developed to combat the airborne nature of the coronavirus.

Standard air filters are rated using the MERV (Minimum Efficiency Reporting Value) system – with MERV8 typical for public buildings. With the Curran Biotech Capture Coating, these filters outperform much higher rated filters in terms of viral protection, without impacting airflow (static air pressure).

Curran Biotech treated filters operate normally with regard to dust and other dry particulates but reject aqueous/liquid-phase contaminants. Because the coronavirus in its most infectious state is surrounded by an aqueous liquid-phase environment, Capture Coating physically stops the virus at the surface of the air filter.

Capture Coating is being made available now from distributors and retailers across the globe. It is already being used in 11 states across the United States and it is to be expanded to 25 with the next few weeks.

Source: curranbiotech.com

Test results show Fiber Bond VE3 chemistry inactivates 99.9% of SARS-CoV-2 in HVAC systems

Fiber Bond announced the release of its VE3 Technology, an engineered chemistry that inactivates SARS-CoV-2, according to test results.

Lab testing concludes that Fiber Bond’s VE3 Technology inactivates 99.99% of the airborne SARS-CoV-2 virus within 15-minutes. The VE3 Technology is a value-added chemistry, developed in-house at Fiber Bond to help stop the spread of COVID-19 in any facility with an HVAC system.

The patent-pending VE3 Technology captures and inactivates the SARS-CoV-2 virus within the nonwoven media of Fiber Bond HVAC air filters. Fiber Bonds VE3 Technology was “evaluated for its ability to inactivate SARS-coronavirus type 2” by Microbac Laboratories, Inc., and “demonstrated a 99.99% inactivation of the virus challenged.”

In March 2020, shortly after the start of the COVID-19 pandemic, Fiber Bond’s team of engineers focused their expertise on the conceptualization and production of an HVAC-compatible filtration product with the ability to capture and eliminate the SARS-CoV-2 virus within an engineered binder system.

In-house research and development of VE3 Technology successfully and swiftly progressed at the Fiber Bond facilities in Michigan City, IN. And, by late 2020, Microbac Laboratories, tested the VE3 Technology for capturing and inactivating the airborne SARS-CoV-2 virus.

“This technology development undertaken by our Fiber Bond technical team is a testament to our ongoing efforts on providing products that enhance air quality. The VE3 technology is focused on providing an additional safeguard against airborne viral particles, specifically COVID-19, and is a great complement to our product portfolio that already includes antimicrobial products. Cleaner air helps to maintain a safer environment for all of us,” said Greg Wilkerson, president & CEO of Fiber Bond and Blocksom & Company.

The VE3 Technology is designed to work in residential, commercial, and industrial HVAC systems to provide equivalent protection against SARS-CoV-2 in high-efficiency air filters. The VE3 Technology is added to the adhesive bonding agent used in the manufacturing of Fiber Bond’s nonwoven filtration media for HVAC applications. VE3 also includes Fiber Bond’s exclusive EPA-certified Spor-Ax antimicrobial agent for eliminating fungal bacteria growth on the filter media.

Source: fiberbond.net

Guidelines doc provides ventilation strategies for COVID-19

The National Occupational Research Agenda (NORA) Manufacturing Sector Council’s COVID-19 workgroup published a guideline document highlighting building ventilation best practices to protect against the spread of airborne pathogens. The document, titled “Ventilation Strategies to Reduce the Risk of COVID-19 in Manufacturing,” is the product of a collaboration between the National Association of Manufacturers and the Centers for Disease Control and is based on input from individuals in business, labor, academia and government. The COVID-19 workgroup is primarily led and operated by non-government members, in order to tailor practices to manufacturing-specific needs. Shortly after the pandemic began, the workgroup assembled to identify information that was not readily available and would be helpful to keep workers safe.

The information is a collection of data, implementation strategies and testimonials on the use of outdoor air, existing industrial ventilation, and heating, ventilation and air conditioning (HVAC) systems to reduce the spread of COVID-19 at manufacturing facilities. These steps can be an important element in a facility’s health and safety plan when implemented within the Hierarchy of Controls, which are control measures, moving from most effective to least effective.

The virus that causes COVID-19 spreads between people more readily indoors than outdoors. Ventilation is a key engineering control at the point of the generation of infectious agents, where the source is infected people.

View the ventilation guidelines here.

Source: nam.org

SGS introduces IC Mark for reusable facemasks in U.S. and Canada

As more and more people around the world rely on the use of face masks to prevent the spread of COVID-19, SGS launched the first Independently Checked Mark (IC Mark) for reusable fabric masks, a new way for consumers in the U.S. and Canada to know if these products conform to industry and regulatory requirements.

The new IC Mark tests and verifies products using key performance attributes from the recently published industry consensus standard, ASTM F3502 Standard Specification for Barrier Face Coverings.

The Mark gives manufacturers and retailers a greater ability to demonstrate their focus on quality and performance, to create and supply products that meet or exceed the minimum legal requirements. In addition, its widespread use will provide consumers across North America with at-a-glance assurance that products satisfy safety and performance claims, and meet regulatory standards.

“Consumers need reassurance from manufacturers and retailers that the reusable fabric masks they are using are performing as intended”, says Matthew McGarrity, Senior PPE Technical Manager for SGS North America. He adds, “They also need to know important criteria such as how many laundering cycles their masks can go through until they are no longer of use.”

SGS in North America, along with other industry experts, helped draft the ASTM F3502 Standard Specification for Barrier Face Coverings. Its criteria include minimum design, performance, and care/use instructions.

Working with leading experts in textiles, filtration and restricted substances, SGS drafted various domestic and mask/face covering guidelines. The IC Mark approval process tests for:

- Breathability

- Particle filtration efficiency

- Labeling

- Strap attachment strength

- Service life claims

- Restricted substances

- Flammability

Source: sgs.com

New ASTM standard establishes minimum requirements for barrier face coverings in the US

According to report by CNN, a new national mask standard outlines minimum fit, design, performance and testing requirements for facemasks and would require user instructions, package labeling and a permanent tag on the product. ASTM International — an international standards organization — spent seven months conducting expedited testing and review and published its guidance on Tuesday. Experts and industry leaders say the new “Standard Specification for Barrier Face Coverings” has the potential to transform the quality of masks available for personal protection in the American marketplace.

“The new specification for barrier face coverings addresses a key gap and will support consumer confidence when purchasing a face covering that’s labeled as meeting the ASTM standard,” ASTM International told CNN in an email.

In a related story, CNN reports several members of President Joe Biden’s former coronavirus advisory board are urging his administration to more widely recommend and mandate the use of N95 masks, citing a “pressing and urgent need for action” driven by the threat of new coronavirus variants.

In a memo to Biden’s top coronavirus advisers obtained by CNN, a dozen health and safety experts — including four members of Biden’s former advisory board — called on the U.S. Centers for Disease Control and Prevention and the Occupational Safety and Health Administration (OSHA) to “recommend and require the use of respiratory protection, such as N95 FFRs (filtering facepiece respirators), to protect all workers at high risk of exposure and infection.”

They also urged the CDC to adopt the first national consumer mask standard and urged the administration to “coordinate a national effort” to distribute National Institute for Occupational Safety and Health-certified respirators and ASTM barrier face coverings to workers in need and use the Defense Production Act to ramp up mask production.

Source: cnn.com

NOTE: INDA, the Association of the Nonwoven Fabrics Industry, will present a webinar explaining the new ASTM F3502-21 Standard Specification for Barrier Face Coverings on Tuesday, March 2, 11 am EST. See the following brief for more details.

INDA adds webinar program to discuss new ASTM facemask standard for the general public

INDA, the Association of the Nonwoven Fabrics Industry, has added a date to its upcoming webinar series, Tuesday, March 2, 11 am EST, to discuss the new ASTM F3502-21 Standard Specification for Barrier Face Coverings, which was introduced by ASTM on February 15. This standard establishes a set of test methods that evaluate the filter, fit and leakage performance of barrier face coverings, commonly referred to as “facemasks,” worn by the general public and not to be confused with respirators nor medical or surgical masks. The webinar will be presented by respiratory expert, Jeff Stull, Vice Chair of the ASTM Committee that wrote the standard, and Dave Rousse, INDA President. It will provide a detailed review of the new ASTM standard and the test methods it entails and the impact on the entire supply chain of facemask production.

The purpose of guidance for the general public to wear facemasks is to control the spread of viruses. Facemasks made to this new ASTM standard will also provide a degree of particulate filtration to reduce the amount of inhaled particulate matter.

“We approached NIOSH last year on developing a general public facemask standard that could use nonwoven materials beyond Meltblown that still deliver an effective level of filtration, as there was so much demand for the N95 respirators and masks once the Asian supply chain was cut off,” said Dave Rousse, INDA President. “We were delighted to get a positive response from Jon Szalajda, NIOSH Deputy Director, National Personal Protective Technology Laboratory, who is also the Chair of the ASTM Committee dealing with standards in this area.”

“This was a worthwhile project that we worked through the ASTM process in record time,” said Szalajda. “It should provide an important benefit in the fight against COVID-19 spread by reducing consumer confusion about what works and what does not and assisting manufacturers in making effective products.”

The goal of the standard is to assist consumers in making informed decisions about facemasks given the vast array of products currently for sale, including various patterns promoted for home-made manufacture using common textile materials. Prior to the ASTM standard, no standard test method existed which allowed comparisons among different products nor were there any minimum performance requirements. This new standard provides these performance requirements as well as a set of specifications, guidelines and expectations for facemask manufacturers and media suppliers.

The Mar. 2 webinar will be in addition to the INDA Webinar Series already scheduled for March 16, March 25 and April 6. For information on the full webinar series, visit www.inda.org/inda-webinars.

Source: inda.org

* International Filtration News is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).

Freudenberg Level 3 surgical masks receive U.S. FDA 510(k) clearance

ASTM Level 3 surgical masks manufactured by Freudenberg Performance Materials recently received 510(k) clearance from the U.S. Food and Drug Administration (FDA). The surgical masks are intended for use by healthcare personnel to protect both the patient and themselves from transfer of microorganisms, body fluids and particulate material. The facemasks are intended for use in infection control practices to reduce the potential exposure to blood and body fluids.

For the U.S. market, Freudenberg Performance Materials is now providing FDA cleared surgical masks meeting the Level 3 standard of the American Society of Testing and Materials (ASTM). The ASTM Level 3 surgical mask is for use in conditions where there is a high risk of fluid and spray of aerosol transmission, such as operating procedures. The masks are a single-use, disposable device provided non-sterile.

Surgical masks by Freudenberg were tested for performance in five areas: fluid resistance, differential pressure, particulate efficiency, bacterial filtration efficiency and flammability. Upon completion of testing, the surgical masks consistently met ASTM Level 3 criteria in all five performance test areas. Bacterial and particle filtration efficiency test results were greater than 99 percent.

The Durham, NC site of Freudenberg Performance Materials began mask production in 2020 in response to the COVID-19 pandemic. Working closely with local partners, Freudenberg is also aiming to prevent future PPE supply shortages by establishing long-term face mask production for the US market. The site manufactures surgical masks and community masks and is pursuing NIOSH N95 respirator certification.

Source: freudenberg-pm.com

Report predicts North American virus filtration market will grow 11.86% per year through 2026

The North America virus filtration market is expected to grow by 11.86% annually in the forecast period and reach $2,554.1 million by 2026, owing to rapid growth of pharmaceutical and biotechnology industry, increasing investments in R&D, surging need for virus removal and clearance amid COVID-19 pandemic. according to a new report by ResearchAndMarkets.com.

The report is based on a holistic research of the entire North America virus filtration market and all its sub-segments through extensively detailed classifications. The report is based on studies of 2016-2019 and provides forecast from 2020 till 2026 with 2019 as the base year.

Specifically, potential risks associated with investing in North America virus filtration market are assayed quantitatively and qualitatively through a Risk Assessment System. According to the risk analysis and evaluation, Critical Success Factors (CSFs) are generated as a guidance to help investors & stockholders identify emerging opportunities, manage and minimize the risks, develop appropriate business models, and make wise strategies and decisions.

Source: researchandmarkets.com

US DHS investigating counterfeit N95 facemask operation

Federal authorities are investigating a massive counterfeit N95 mask operation in which fake 3M masks were sold in at least five states to hospitals, medical facilities and government agencies. The foreign-made knockoffs are becoming increasingly difficult to spot and could put health care workers at grave risk for the coronavirus.

These masks are giving first responders “a false sense of security,” said Steve Francis, assistant director for global trade investigations with the Homeland Security Department’s principal investigative arm. He added, “We’ve seen a lot of fraud and other illegal activity.”

Read the full story: https://apnews.com/article/government-investigation-n95-scam-1694ed85d6ef99cdb6662f67d823c271

Source: https://apnews.com/

CDC research shows tight-fit masks or double masking with cloth and surgical masks increases protection

Wearing a mask — any mask — reduces the risk of infection with the coronavirus, but wearing a more tightly fitted surgical mask, or layering a cloth mask atop a surgical mask, can vastly increase protections to the wearer and others, the Centers for Disease Control and Prevention reported on Wednesday, as reported by The New York Times.

New research by the agency shows that transmission of the virus can be reduced by up to 96.5 percent if both an infected individual and an uninfected individual wear tightly fitted surgical masks or a cloth-and-surgical-mask combination.

Read the full story: https://www.nytimes.com/2021/02/10/world/double-mask-protection-cdc.html

Source: nytimes.com

Oerlikon Nonwoven, Wolf PVG commission meltblown plant for FFP2 masks

Oerlikon Nonwoven has commissioned a double-beam meltblown plant with ecuTEC+ electro charging unit at Wolf PVG GmbH & Co. KG. With this plant, the East Westphalian company can now provide nonwovens for the production of surgical and FFP2 masks. In addition to this filter material, which is in great demand today, high-quality meltblown nonwovens can also be produced for medical and industrial filter applications. The plant has now been running for several weeks under stable production conditions with optimal nonwoven fabric quality of the highest standards.

With the beginning of the COVID-19 pandemic and the shortage of protective masks that ensued, Wolf PVG GmbH & Co. KG, a wholly owned subsidiary of the Melitta Group, switched part of its production capacities to nonwoven mask fabric production. As a highly specialized system supplier for everything to do with vacuum cleaners and industrial filter technology, the company from East Westphalia can fall back on its extensive know-how and many years of experience.

With the meltblown plant from Oerlikon Nonwoven, Wolf PVG is further expanding its production capacities. The plant, with its two beams and the ecuTEC+ electro charging unit, is optimally designed for the production of face mask material. The plant is also ideal for the production of other filtration nonwovens. “A decisive point for investing in a plant from Oerlikon Nonwoven was the flexibility of the plant in relation to the possible product portfolio and the competence of the manufacturer,” said Markus Seele, COO of Wolf PVG. Dr. Ingo Mählmann, senior vice president of Sales & Marketing for Oerlikon Nonwoven, said, “Thanks to the numerous setting options for the electrostatic charge provided by the ecuTEC+, the optimum loading status can be set depending on the filter application.”

Source: oerlikon.com

ASHRAE Epidemic Task Force updates HVAC guidance for SARS-CoV-2

As the performance of many HVAC systems in buildings are still being evaluated, the ASHRAE Epidemic Task Force has updated its reopening guidance for HVAC systems to help mitigate the transmission of SARS-CoV-2.

“The Building Readiness Guide includes additional information and clarifications to assist designers and commissioning providers in performing pre- or post-occupancy flush calculations to reduce the time and energy to clear spaces of contaminants between occupancy periods,” said Wade Conlan, ASHRAE Epidemic Task Force Building Readiness team lead. “New information includes the theory behind the use of equivalent outdoor air supply, method for calculating the performance of filters and air cleaners in series, and filter droplet nuclei efficiency that help evaluate the systems’ ability to flush the building.”

Major updates to the building readiness guidance include the following:

- Pre- OR Post- Flushing Strategy Methodology: The strategy has been updated to include the use of filter droplet nuclei efficiency, which is the overall efficiency of filter based on viable virus particle sizes in the air, to assist in determining the impact of the filter on the recirculated air on the equivalent outdoor air. This allows the filter efficiency as a function of particle sized, using on ASHRAE Standard 52.2 test results, to be estimated based on the expected size distribution of virus-containing particles in the air. This calculation is currently based on Influenza A data and will be updated as peer-reviewed research becomes available for the distribution of particle sizes that contain a viable SARS-CoV-2 virus. Additionally, a chart added to help determine the time to achieve 90%, 95%, or 99% contaminant reduction if the equivalent outdoor air changes per hour is known.

- Flushing Time Calculator: There is now a link to a view-only Google Sheet that can be downloaded for use, to help determine the available equivalent outdoor air changes and time to perform the flush. This sheet is based on a typical mixed air AHU with filters, cooling coil, with potential for in AHU air cleaner (UVC is noted in the example), and in-room air cleaning devices. Provided efficiencies of MERV rated filters are based on the performance of over 200 actual filters from MERV 4 through 16, but the tool also allows users to enter custom characteristics for specific filters.

- This sheet also calculates the filter droplet nuclei efficiency based on the cited research but allows a user to adjust the anticipated distribution of virus as desired. It also allows specification of the zone (room) air distribution effectiveness from ASHRAE Standard 62.1 to account for the impact of the HVAC system air delivery method on the degree of mixing. Default calculations assume perfect mixing. Finally, the tool allows for the target air changes to be adjusted if an owner wants to achieve a different percent removal in lieu of the recommended 95%.

- Heating Season Guidance: the guide now includes data to consider for heating of outdoor air and the potential impact on pre-heat coils in systems.

- Adjustments to Align with Core Recommendations: The Core Recommendations were released in the last month and this guidance document needed to be updated to ensure that the information provided aligned with the intent of those recommendations. This included minimum outdoor air supply and filter efficiency requirements and their role in an equivalent outdoor air supply-based risk mitigation strategy.

The guidance still addresses the tactical commissioning and systems analysis needed to develop a Building Readiness Plan, increased filtration, air cleaning strategies, domestic and plumbing water systems, and overall improvements to a systems ability to mitigate virus transmission.

To view the complete ASHRAE Building Readiness guide and other COVID-19 resources, visit ashrae.org/COVID-19.

Source: ashrae.org

Porex medical device filtration materials shown to protect against spread of bacteria and viruses

Porex is one of the first in industry to initiate VFE testing for its porous polymer-based materials; results show components protect against certain aerosolized viruses

To address the spread of healthcare-associated infections (HAIs) from aerosolized viral particles, Porex Corporation, a global leader in porous polymers, has pioneered the use of VFE testing methods for materials used in medical device design. Likely the first in the porous polymer material science industry to run the new analysis on filtration media, the components were able to consistently obtain a 99.9987% VFE score, showing that its materials effectively help to protect healthcare workers and patients from aerosol-based viruses potentially present in medical settings.

Porex initiated VFE testing for its materials after observing the needs of its customers, which frequently fielded concerns from patients and healthcare workers seeking information that the components used in various equipment procedures would not pose risks of a HAI contraction.

Nearly one in 31 hospital patients acquires a HAI—and these infections lead to an estimated 99,000 annual deaths in American hospitals alone, according to the Centers for Disease Control and Prevention (CDC). Healthcare workers face similar—if not greater—threats due to frequent exposure to viral pathogens.

“The pandemic has magnified what was already a pressing issue in healthcare settings around the world, which is that inadequate filtration materials put patients and professionals at risk of contracting dangerous viruses,” said Avi Robbins, vice president, global product development and R&D at Porex. “We took the step to lead the materials industry into VFE testing to validate efficacy, and we are thrilled to confirm that our filtration and venting components are trustworthy and reliable for blocking viral particle spread.”

Porex develops venting and filtration solutions by leveraging several core technology platforms such as sintered particles, bonded fiber, PTFE and Oxyphen track-etched membranes. Filtration and venting media from Porex are suitable for suction canisters, catheters, syringes and other medical equipment utilized in aerosol-generating medical procedures.

Source: porex.com

MBT, Polyguard announce licensing agreement on nano silver antimicrobial tech for facemasks and filter media

MeltBlown Technologies (MBT) of Sandersville, Georgia, has entered an exclusive license agreement with Polyguard Group, to integrate Polyguard’s antimicrobial technology with MBT’s meltblown facemask and filter media.

In 2020, MBT was able to convert its traditional industrial and construction product model into producing meltblown filtration materials for facemasks. MBT was determined to find ways to improve on existing facemask materials and began collaborating with Polyguard Group to create meltblown products with antimicrobial properties.

“Once we met with the team at Polyguard we could see immediately that these guys were innovators. They have created one of the most unique and important antimicrobial technologies the world has ever seen.” said MBT president, Derek Yurgaitis. “I was completely blown away by the nano silver technology, its unique mechanism of action and the potential to be game changing in the fight against infections. Polyguard has already successfully inhibited Corona virus with a 99.15% reduction. We can now begin to imagine materials from HEPA filters to Facemasks that prevent microbes from replication on their surfaces.”

AFS FiltCon 2021 announces all-virtual format

Due to ongoing concerns surrounding COVID-19, as well as continued travel restrictions around the world, the American Filtration & Separation Society (AFS) has made the decision to shift AFS FiltCon 2021 to a fully virtual event.

The virtual edition of FiltCon 2021 will consist of two concurrent tracks, taking place over three days, April 19 – 21, 2021. The virtual setting will allow for conference attendees to participate in a total of 36 technical presentations, as all sessions will be available to conference registrants on-demand for two weeks after the live broadcast of presentations. Normally FiltCon provides four concurrent tracks with the ability for conference attendees to participate in a total of 24 technical presentations. By offering two concurrent tracks over three days, the virtual AFS FiltCon 2021 allows conference attendees to participate in a total of 36 technical presentations.

Source: afssociety.org

Mask-Alliance Bavaria certifies FFP2 facemask; production to begin at Zettl Group plant in Weng

Founded in May 2020, in response to the COVID-19 pandemic, the Mask-Alliance Bavaria established a complete value chain for the manufacture of facemasks in Germany. In its latest development, the Futurus facemask has been certified as an FFP2 protective mask. In December, production will start at alliance member Zettl Group’s plant in Weng, Bavaria.

Since the beginning of this initiative to produce mouth-nose protective facemasks, the founding members of the Mask-Alliance Bavaria – PIA Automation (automation specialist from Amberg), Sandler Group (manufacturer of high-tech nonwovens from Schwarzenbach/Saale) and Zettl Group (leading supplier in the field of automotive interiors) – had been working to produce certified FFP2 masks in Bavaria.

On December 3rd, Jörg-Timm Kilisch, Managing Director of DEKRA Testing and Certification GmbH, officially presented the certificate at the Zettl Group company site in Weng, Landshut district.

FFP2 or FFP3 masks are particularly recommended as personal protective equipment for healthcare workers who are exposed to an increased risk of infection in their work. The quality of the filter medium, the mask design, the fit and the available filter area are decisive for the classification of the product. In joint development work and close cooperation with the new association member DEKRA, the certification process was successfully completed at the end of October.

The fully automated production lines in Weng will now produce up to 6 million Futurus masks per month. An expansion of the production capacity to up to 10 million masks per month is already being planned. The Mask-Alliance Bavaria is thus expanding its contribution to securing the supply of these important medical products.

Source: masken-verbund-bayern.de

WHO issues updated guidance on mask wearing for COVID-19

The World Health Organization (WHO) updated its guidance published on 5 June 2020 based on new scientific evidence relevant to the use of masks for reducing the spread of SARS-CoV-2, the virus that causes COVID-19, and practical considerations. It contains updated evidence and guidance on the following:

• mask management;

• SARS-CoV-2 transmission;

• masking in health facilities in areas with community,

cluster and sporadic transmission;

• mask use by the public in areas with community and

cluster transmission;

• alternatives to non-medical masks for the public;

• exhalation valves on respirators and non-medical masks;

• mask use during vigorous intensity physical activity;

• essential parameters to be considered when manufacturing non-medical masks (Annex).

Read the updated guidance: https://apps.who.int/iris/rest/bitstreams/1319378/retrieve

Source: who.int

Why ventilation is key to battling COVID-19

As the weather gets colder and people head indoors, the risk of catching COVID-19 is rising. The Wall Street Journal published a video explaining why air ventilation and filtration are one of the best defenses against the coronavirus this winter. The piece does an excellent job of highlighting why MERV-13 filtration is important to indoor air quality.

Watch the video: https://www.wsj.com/video/ventilation-is-key-to-battling-covid-heres-why/EC6274D1-B4F0-40DF-A8EC-F9BDA7C5D1A1.html

Source: wsj.com

FILTECH 2021 postponed

With the expectation that Germany will be restricting large events through the first quarter of 2021 due to ongoing complications from the COVID-19 pandemic, FILTECH 2021, which was scheduled to take place Feb. 23-25 in Cologne, has been postponed. New dates have not yet been announced.

Conference organizers are working to identify dates to reschedule the event.

Source: filtech.de

HanesBrands facemask receives US FDA authorization

HanesBrands announced that a proprietary surgical facemask developed in conjunction with North Carolina State University, the University of North Carolina at Chapel Hill and UNC Health has been authorized by the U.S. Food and Drug Administration for use by health care professionals as personal protective equipment.

The two-ply, single-use surgical mask features a unique fabric developed by NC State’s Nonwovens Institute combined with a fit design created in collaboration with UNC-Chapel Hill and NC State biomedical engineers and UNC Health infection prevention experts.

The Hanes mask uses a duckbill shape for better breathability, a wire nosepiece and foam insert to enhance a contoured fit, and placement of stretchable straps for a secure fit. UNC Health tested the masks to assure they meet FDA particulate filtration standards and OSHA respiratory protection program requirements.

The FDA issued its Emergency Use Authorization for surgical masks in response to concerns relating to the insufficient supply and availability of disposable single-use surgical masks that provide a physical barrier to fluids and respiratory droplets.

The use of unique spun-bond fabric developed by the Nonwovens Institute, the world’s first accredited academic program for the field of engineered fabrics, eliminates the need for a third filtration layer for cost efficiency and filtering effectiveness. The spun-bond fabric is composed of two different polymer materials to make a single fiber that has significant strength and bulk that is as effective in filtration as current materials on the market.

Source: hanes.com/corporate

New company positions HEPA/UVGI air cleaning technology as an effective tool against COVID-19

A New Hampshire company, Air Cleaners Inc., has designed and developed a patented air cleaner that it says can play a critical role as we try to adapt to life in the age of COVID-19.

The company—formed by airflow experts from the semiconductor cleanroom and data center industry—was created to address aerosol transmission of pathogens using the experience and insight of its founders based on their decades of work modeling airflows in mission-critical facilities.

The company’s new product–the Clean Air Curtain(TM)–combines HEPA filtration and Ultraviolet Germicidal Irradiation (UVGI) with an “air curtain” high velocity exhaust to create a separation in local indoor airspaces. Their approach of utilizing HEPA level filtering together with UVGI lighting in a small, portable, desktop package represents a state-of-the-art process for producing the cleanest air possible while providing many unique and significant advantages, according to the company.

The Clean Air Curtain is complementary to local HVAC systems, as many buildings are without whole-building HVAC systems, or have inadequate fresh air ventilation. In these cases, the best method of clearing the air of pathogens is to use portable filtration devices.

Source: aircleanersinc.com

Data suggests cotton batting can increase the filtration efficiency of cloth facemasks

Recent FDA chief Scott Gottlieb, Ph.D., argued that he’d “rather try to get everyone in masks” and “try to get them in high-quality masks because we know it’s going to slow down the transmission.”

Against this backdrop, a new study published in Risk Analysis, “Reinventing cloth masks in the face of pandemics,” by Stephen Salter, P.Eng., describes how Effective Fiber Mask Programs (EFMPs) can help communities find a balance between the economy and curbing community spread.

A separate study by Stadnytskyi, et al. estimates that one minute of loud speaking generates at least 1,000 virion-containing droplets that remain airborne for more than eight minutes. If everyone uses effective masks, the benefit is compounded because each person’s mask reduces the number of particles they transmit, and also the number of particles they inhale.

The new study in Risk Analysis suggests that the effectiveness of cloth masks can be improved by using a non-woven material such as cotton batting. Increasing the surface area of fibers exposed to moving air improves filtering efficiency because the smaller particles are absorbed onto the fibers. In May and June of 2020, 17 handmade cotton batting masks underwent 35 tests using commercial quantitative fit testing equipment to determine their filtering effectiveness. The results showed average filtering effectiveness of 76 to 90 percent against aerosol particles.

Read the full story: https://www.sra.org/2020/10/23/new-data-on-increasing-cloth-mask-effectiveness/

Source: https://www.sra.org/

PureAir Filtration, Nobel Biomaterials partner to develop antimicrobial fiber for filtration

PureAir Filtration, a company specializing in removing corrosive gases, toxic vapors and odors, announced it has launched a strategic partnership with Noble Biomaterials, a leader in antimicrobial and conductivity solutions for soft-surface applications. The companies have developed an antimicrobial fiber called FiberShield that can be used as an added fabric layer in particulate filters to help fight microbes amid the COVID-19 pandemic.

FiberShield is made of a proprietary blend of nonwoven nanofibers that are impregnated with antimicrobial Ionic+™ silver technology. The antimicrobial fabric can be used in any particulate filter and is the only one on the market to offer such flexibility to filter manufacturers. FiberShield with Ionic+ technology has been tested and proven effective by independent testing laboratories to inactivate over 99% of specific pathogens.

PureAir also debuted a second product in its antimicrobial line called Microbe-sorb, an adsorbent media that utilizes a proprietary blend of compounds to activate, enhance and deliver the strong antimicrobial properties of permanganate, a material commonly used in medical practices since the early 1800s. Independent laboratory tests show Microbe-sorb inactivates over 99% of microbes on contact.

Source: pureairfiltration.com

Lidl to install hospital-grade air filters in all U.S. stores, aims to prevent spread of COVID-19

Following recently issued Centers for Disease Control (CDC) guidelines stating that the COVID-19 virus can be spread through the air, Lidl US announced it will install new air filtration systems rated MERV 13 or higher in all of its U.S. stores by the end of this year. Air filters rated MERV 13 or higher, which are typically found in hospitals, help filter out COVID-19, according to public health and industry leaders.

“Since the beginning of the pandemic, we have worked diligently to protect the health of everyone in our stores by meeting or exceeding CDC guidelines and this measure to create cleaner, healthier air is no different,” said Johannes Fieber, CEO of Lidl US. “Customers and team members in Lidl stores can breathe easier knowing we have an added layer of protection against COVID-19.”

Lidl US is among the first national grocery retailers to install hospital-grade air filtration systems across its entire store network. Previously, Lidl stores used advanced commercially rated MERV filtration systems. Epidemiologists and professional associations have recommended using high-efficiency air filters MERV 13 or higher wherever technically feasible to trap small airborne particles that can transmit the virus.

Source: lidl.com

Meat processing giant, Tönnies Group, leverages Camfil air cleaners as part of pandemic prevention scheme

Camfil has entered an agreement with Tönnies Group, Germany, for the implementation of an air filtration concept at a meat production facility at Tönnies headquarters. The aim is to set high hygiene standards for the sensitive food area and focus on improved indoor air quality at the facility.

In food production facilities, air is the invisible ingredient, and better air quality can help the facility achieve operational excellence and great quality product along with employee health. Often, the lack of standards in the meat production industry around ventilation and limitations in the design of the facility can lead to poor airflow along with insufficient positive pressure in the indoor environment. Also, to achieve the temperatures of around 6 C to 10 C required for meat processing, Tönnies uses convection coolers. They cool the circulating air and return it to the room for reuse. Scientific studies have shown, that airborne pathogens such as viruses can spread through this air recirculation. Germs packed in aerosols is 80 nanometers to 160 nanometers in size and can remain active in the air for up to three hours. These convection coolers can distribute the pathogens in the room and significantly increase the risk of infection for employees.

Due to the global pandemic, Coronavirus (COVID-19), Tönnies Group concluded that they want to protect their facility and employees from these harmful pathogens in the air. They aim to provide healthy, sustainable food with responsible production that meets high standards. The new multi-level hygiene solution consists of high-efficiency HEPA air cleaners, certified with EN1822:2019 from Camfil. These air cleaners (CC 6000 and CC 2000) with ProSafe HEPA H14 filters clean the indoor air from the circulating aerosols or viruses and provide clean filtered air to the cooling system for circulation. The systems were positioned at an elevated position so that the air cleaners can get a good flow of air through the production rooms and at the same time do not interfere with operations.

Initial measurements, which were carried out shortly after the installation, showed particle reduction by more than 50%.

Source: camfil.com

Nanotech coating for filters shows promise in capturing aerosolized virus particles

A physics professor from the University of Houston has developed a nanotech coating designed to allow air filters to capture airborne or aerosolized droplets of the virus that causes COVID-19.

The coating works by capturing liquids which encase the virus particles while still allowing air to flow through unimpeded. That allows ventilation systems to remove the virus during normal operation, without retrofitting or limiting the system’s ability to draw fresh air, said Seamus Curran, a physics professor known for his work commercializing nanotechnologies.

The coated filters are currently installed in one public building in New York City.

Balancing filtration with air flow is critical to indoor air quality, a key issue as colder weather in some parts of the country pushes more people indoors.

Curran, on the faculty of UH’s College of Natural Sciences & Mathematics, has worked with waterproof coatings, known as hydrophobic coatings, for almost a decade. The filter coating is a new water-based version designed to capture airborne virus particles, trapping them on the filter’s coating without limiting air flow.

He said the treated filters should be used in conjunction with other precautions, including masks and social distancing.

Read the full story at: https://www.uh.edu/nsm/physics/news-events/stories/2020/0929-filter-coating.php

Source: https://www.uh.edu/

Waterloo Filtration Institute to present Annual Conference with a focus on IAQ & COVID-19

The Waterloo Filtration Institute (WFI) will present its 2020 Annual Conference, December 15-16, 2020, 8:00 am -12:00 pm EST. The theme of the event will be “IAQ Health and Safety Solutions Associated with COVID-19”. It will address the critical roles of facemasks and air filtration during the current pandemic for public health and safety.

The virtual conference will feature the following four sessions:

1. Emerging Challenges and Responses

2. IAQ and the Built Environment

3. Facemask Technologies and Latest Developments

4. Facemask/Air Filter Test Methods and Standards

The event will feature 16 distinguished speakers from academia and the industry to share their latest developments and trends on IAQ health and safety solutions in response to the pandemic.

WFI is dedicated to supporting the growth of the global filtration industry and the advancement of filtration and separation processes for a clean, healthy, and sustainable world.

For full program details and to register, visit wficonference.org.

Freudenberg to add meltblown capacity in Europe

Freudenberg Performance Materials (Freudenberg) is expanding its production capacity for nonwoven media used exclusively to manufacture certified facemasks of the mouth-nose protection type pursuant to the EN14683 standard, as well as FFP1, 2 and 3 masks pursuant to the EN149 standard. The media are specially developed for and sold to the medical technology processing industry. To that end, Freudenberg is investing in the construction of a new state-of-the-art meltblown production line at the Kaiserslautern site. Commissioning of the new plant is slated for the first quarter of 2021.

“As a world-leading manufacturer of technical textiles and filtration media, Freudenberg Performance Materials has deep expertise in materials for certified face masks. By expanding our production capacity in Kaiserslautern, we are making a contribution to mastering the challenges presented by COVID-19 and supplying certified type face masks as well as FFP1, FFP2 and FFP3 masks in Germany and Europe”, said the CEO of Freudenberg Performance Materials, Dr. Frank Heislitz.

With the new line, Freudenberg is significantly expanding production capacity for meltblown nonwovens in Kaiserslautern. The world-leading technical textiles manufacturer produces these materials from extremely fine meltspun polypropylene microfibers that are several times thinner than a human hair. Masks made of these nonwovens can filter very small particles such as viruses thanks to the superfine structure of the material and its electrostatic charge.

Source: freudenberg.com

SWM increases production of air filtration media, as COVID-19 drives demand

In response to customer demand that has more than doubled over the past year, SWM International is ramping up production of its Alphastar Electrostatic Media product at its Wilson, North Carolina manufacturing facility. Alphastar Electrostatic Media is a primary component in HVAC air filtration products, including MERV 13-rated air filters.

“We began to see demand rising in April due to the COVID-19 pandemic, and quickly developed ongoing plans to support our customers. Expanding our output was critical, as we are an essential supplier to many of the largest air filtration companies in the U.S. SWM is determined to do everything we can to help our customers deliver the air filters and medical respirators that are vital tools in stopping infection spread and improving indoor air quality,” said Bart Sistrunk, Commercial Director of Filtration for SWM.

The company is expanding the workforce at the facility to support the higher production level and is continuing to evaluate further actions to increase output. This follows efficiency projects earlier in 2020 to increase capacity on the existing production lines. SWM anticipates ongoing demand for Alphastar media as commercial and residential customers respond to recommendations from the Centers for Disease Control (CDC) and ASHRAE (American Society of Heating, Refrigeration and Air-Conditioning Engineers) to upgrade building filtration to a minimum of MERV 13, which requires more frequent changes compared to lower level filters such as MERV 8.

The proprietary fiber blend in SWM’s Alphastar media is carded and needled into a fully homogenous material, making it a highly effective nonwoven for a variety of air filtration applications, including emergency respirators, N95 masks, CPAP (continuous positive airway pressure) machines, and ventilators.

Source: swmintl.com

Freudenberg facemask receives EN 14683 certification

Freudenberg Filtration Technologies announced its German-made facemask design has been certified as a TYPE II medical facemask according to EN 14683.

Freudenberg Filtration Technologies completed all the necessary certifications within a few weeks.

“At the heart of our medical face masks is a soft three-layer polypropylene filter medium that is characterized by its superior breathability,” said Dr Thomas Caesar, Director Global Filter Engineering Industrial Filtration at Freudenberg Filtration Technologies.

The three-layer design reduces the release of aerosols contaminated with viruses and bacteria. Freudenberg Filtration Technologies says that external laboratory tests confirm a filtration efficiency of more than 98% in aerosol separation.

The independent dermatological institute Dermatest has rated the product’s skin compatibility as “excellent,” according to Freudenberg. Elastic ear loops and a nose clip allow Freudenberg Filtration Technologies’ mouth-nose protection to be individually adjusted and ensure a comfortable fit.

Freudenberg is only supplying the certified facemasks to companies that order 7,500 units or more.

Source: freudenberg-filter.com

NWI’s spunbond high-efficiency filter media wins RISE Innovation Award

More than 150 professionals in product development, materials science, and new technologies convened for the 10th conference edition of RISE—Research, Innovation & Science for Engineered Fabrics, held virtually, Sept. 29-Oct. 1. The event was co-organized by INDA, the Association of the Nonwoven Fabrics Industry, and The Nonwovens Institute, and North Carolina State University.

Among the program highlights was the presentation of the RISE Innovation Award, which was presented to The Nonwovens Institute at North Carolina State University for its Spunbond High-Efficiency Filter Media. The product is a completely new approach to creating filtration media with the right efficiency at low pressure drop at a throughput of 350 kg per meter per hour. The pressure drop with The Nonwovens Institute’s new filter is unmatched by any meltblown structure and doesn’t require electrostatic charging, which has been an obstacle to facemask manufacturing during the COVID-19 pandemic. The materials is also much stronger than traditional meltblown filter media, thus providing the potential for reuse after appropriate cleaning and disinfection.

NWI won the 2020 RISE Innovation Award for its new spunbond filtration media. Photo: INDA

NWI said it has produced 4.5 million meters of the material so far, enough to produce 100 million masks.

Other nominees for the award included FemTech at MAS Holdings Pvt. Ltd. for its leakproof absorbent nursing pads and Sustainable Solutions Incorporated for its BlueCON Nonwovens initiative that produces recycled resin from hospital waste.

Source: riseconf.net

Researchers develop graphene filtration technology to neutralize organic particles, including bacteria, mold spores & viruses

Technology developed by researchers at Ben-Gurion University of the Negev (BGU) in Israel in partnership with Rice University in Houston, Texas is being commercialized by LIGC Application Ltd. to develop and manufacture products for filtration systems, including those that filter COVID-19 airborne particles.

LIGC is a company at the forefront of laser-induced graphene (LIG) commercialization. Hubei Forbon Technology Co. Ltd. (300387.SZ) in Wuhan, China provided $3 million in funding.

LIGC Co-founder and Chief Executive Officer Yehuda Borenstein says, “In the absence of better filtration technology, the indoor spaces where we used to spend most of our ‘normal’ life—schools, stores and workplaces— due to COVID-19 present a real risk. This technology will provide cleaner and more breathable air with lower energy and maintenance costs and virtually silent sound levels.”

Active air filters made with LIG are designed to damage and destroy organic particles including bacteria, mold spores and viruses at the micron and sub-micron levels when passed through a microscopic network of porous graphene.

This cost-effective and scalable approach is produced using commercially available CO2 lasers to create a conductive graphene mesh. The graphene mesh heats, electrocutes and neutralizes organic particles and pathogens with revolutionary efficiency compared to active carbon filters, UV-C and fiber HEPA filters that are used widely in schools, offices, homes, ships, and other facilities. Aircraft are already equipped with HEPA filters that remove viruses and bacteria from the circulated cabin air, but at high energy and maintenance costs.

Source: ligcapp.com

Source: aabgu.org