North Carolina State University Researchers Develop an Air Filtration Technology that Catches and Kills Pathogens with up to 99.9% Efficiency

While the need for effective air filtration technologies has long been recognized, traditional solutions such as high-efficiency particulate air (HEPA) filters and ultraviolet light (UVC) devices have demonstrated limitations in providing comprehensive pathogen removal and deactivation, particularly during COVID-19. In response to these challenges, North Carolina State University (NC State) researchers have developed a groundbreaking air filtration technology – SPAR (Smoke and Pathogen Air Removal), formerly known as FIL-TEX, that offers a viable alternative for the 21st century.

For decades, HEPA filters have stood as the gold standard in air filtration. Their impressive 99.9% efficiency in capturing small particles and pathogens has made them a staple in healthcare, education, transportation, and other settings. However, HEPA filters have inherent drawbacks. They excel at capturing pollutants but fall short in deactivating bacteria and viruses, making filter replacement a potentially hazardous endeavor.

Dr. Warren Jasper, a professor at NC State, explains, “Because HEPA filters merely capture particulates and pathogens and focus them in one place, there is a strong likelihood that any collected bacteria or viruses will be re-aerosolized when replacing the filter.”

Furthermore, HEPA filters are typically positioned within air handling systems, which limits their effectiveness. Even when added to an air purifier, they fail to offer widespread protection. “Essentially, HEPA filters are often placed too far away to provide protection to areas where people are congregating,” Jasper says.

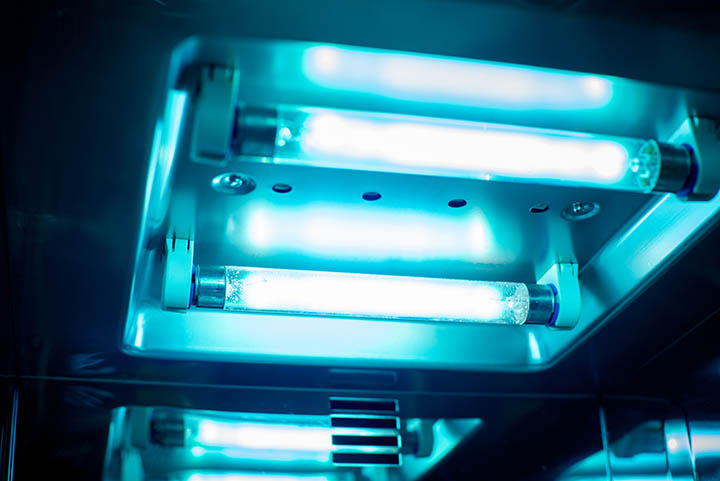

Ultraviolet light disinfection technologies (UVC) have gained popularity for their ability to deactivate live pathogens by destroying their DNA. However, just like HEPA filters, UVC systems have their own set of challenges including potential health risks such as headaches and skin cancer for individuals overexposed to UV light. Furthermore, integrating UVC technologies with HVAC systems can increase operational and maintenance costs due to higher power requirements and costly bulb replacements.

A 21st Century Air Cleaning Technology Emerges

Recognizing the limitations of these decades-old technologies, NC State researchers embarked on a mission to develop a cutting-edge solution that addresses the unique challenges of today’s world.

“Filtration of airborne particulates can be divided into two camps – active and passive. We decided to take the best performance characteristics from passive technologies that capture particulates and active technologies that purify the air and combine them into a single, more modern air cleaning solution,” Jasper says.

The result of their innovative endeavor is SPAR, which represents a fusion of the finest attributes of HEPA filters and UVC devices, encapsulated within a flat, lightweight, non-thermal plasma-enhanced textile. This innovative textile filter excels at both capturing and killing bacteria, viruses, and other contaminants, boasting an impressive 99.9% efficiency.

The Science Behind SPAR

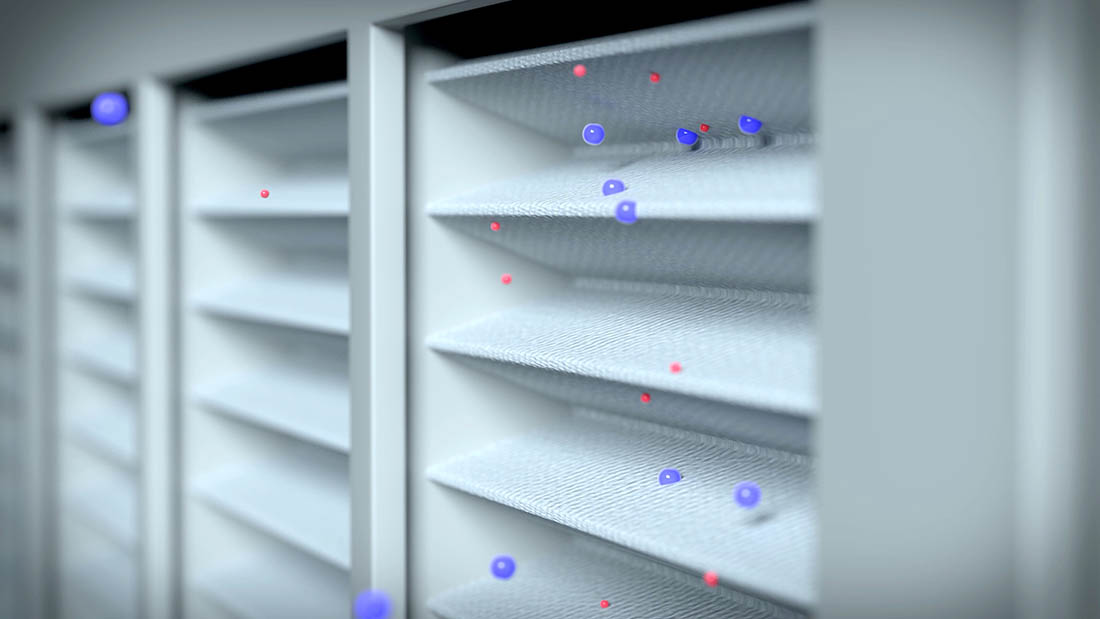

SPAR technology is built on a foundation of woven, knit, or non-woven structures. Within these structures, non-conductive yarns are combined with conductive yarns that serve as electrodes. When voltage is applied to these conducting yarns, they generate a non-thermal plasma (NTP).

Non-thermal plasma, often referred to as cold plasma, represents an electrically energized state of matter that remains cool to the touch. It is composed of a partially ionized gas that reacts with pathogens, chemicals, odorants, and other contaminants, converting them into harmless oxidized forms. When airborne pathogens pass through the SPAR filter, the NTP reacts with the sheath membrane of the microorganisms, deactivating the virus or destroying the cell wall of the bacterium, effectively eliminating airborne pathogens while safely collecting them.

Essentially, SPAR operates as a magnet that attracts, deactivates, and removes unwanted contaminants from the air, all without emitting any additives or substances into the environment.

SPAR technology is built on a foundation of woven, knit, or non-woven structures. Within these structures, non-conductive yarns are combined with conductive yarns that serve as electrodes. When voltage is applied to these conducting yarns, they generate a non-thermal plasma (NTP).

Proven Efficacy of SPAR

The need for an air filtration technology that can eliminate aerosolized pathogens is now more evident than ever, particularly in confined spaces where people frequently gather. Dr. Frank Scholle, Associate Professor of Biological Sciences at NC State, explains, “While good air circulation helps reduce the likelihood of the transmission of airborne viruses and bacteria, effective filtration is crucial in locations where there is not much air turnover and in which we pack a lot of people.”

To validate the efficacy of SPAR, researchers in Scholle’s virology lab conducted extensive testing. They introduced an aerosolized coronavirus, genetically similar to the virus responsible for COVID-19 infections, into a laboratory-scale tunnel with SPAR situated between the inlet and outlet. Air samples collected before and after passing through SPAR demonstrated impressive post-filtration effectiveness, with nearly a 3-log reduction in infectious virus, equivalent to up to 99.7% effectiveness.

Following the successful tests at NC State, SPAR underwent independent analysis at CREM Co Labs, a specialized R&D laboratory focusing on antimicrobial testing. The results were equally compelling, with SPAR proving its ability to remove over 99.9% of airborne viruses, including COVID-19, and 99.9% of airborne bacteria like staph, while deactivating 98% of viruses found on the filter’s surface.

SPAR’s versatility extends beyond pathogens. It has demonstrated rapid absorption of continuous smoke and particulates such as oil, carbon, soot, ash, and tar in enclosed spaces where venting is not feasible, making it a versatile air cleaning technology with numerous potential applications.

Implementing SPAR Technology

The SPAR filter can be crafted from various fabrics, including cotton, polyester, polypropylene, Kevlar, and others. Its lightweight, flat design, with a thickness of only about 2 mm, facilitates high airflow while requiring minimal power consumption. This versatility allows for integration into various air cleaning devices and systems, including wall- or ceiling-mounted units and HVAC systems.

Currently, SPAR technology is available through Stitch Partners, which holds the intellectual property license from NC State. Manufacturers of air cleaning devices can incorporate SPAR as a component in the development of new or existing systems.

For more information, contact Stitch Partners by phone at (978) 880-3783, via email at info@stitchpartners.com or visit https://stitchpartners.com.