Indoor air quality, or IAQ, is such an import topic today because, depending on the research you have in hand, the average person is spending up to 90 percent of their time indoors. And, much to the layperson’s surprise, the air quality within the indoor environment is often more seriously polluted than outdoor air – even in the largest and most industrial cities.

For this reason, there is a lot of work being done to identify solutions that can measure air quality efficiently and cost effectively. At the same time, government regulations are putting pressure on commercial and industrial business to ensure a certain level of air quality within their environments.

Interestingly, however, the Occupational Safety and Health Administration (OSHA) here in the United States has not yet issued a standard that directly addresses IAQ. Meanwhile, ASHRAE and ISO are promoting two different standards for indoor air quality, and countries who are not allied to ASHRAE or ISO are, in many cases, are following hybrid or outdated IAQ standards. It’s a bit of a mess, to be honest, and there is much work to be done to ensure homes and facilities around the world provide adequate air quality for the people who inhabit them.

Sources of chemical pollutants (gases and vapors) come from five main categories: products used in the building; products that can get pulled into the HVAC system from outside the building; accidental spills; products used during construction activities; and byproducts of combustion such as carbon monoxide, formaldehyde, and nitrogen dioxide.

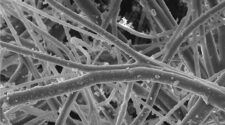

Digital IAQ sensors are providing needed data to track, analyze, and clean air in the ambient environment.

Image courtesy of iStock.com/Suebsiri.

Consider the tightening of a building envelope … A tight home may be incapable of providing make-up air for exhaust fans, a clothes dryer or vented combustion equipment. The negative pressure in the home caused by these appliances can draw exhaust gasses back into the home (back drafting), and also force air through the building envelope and create moisture/mold problems as humid air condenses within the building envelop. This is a problem that deserves some consideration.

Consider the consequences of plastics around the fireplace … With the advent of flat screen TVs, many homes and businesses have located their television directly over one of the largest heat sources in the living space – a fireplace. This area is generating a lot of heat, and surrounding surfaces are heated dramatically, so much so that there is a potential for plastics to off-gas. Are our in-home filtration systems capable of mitigating this off-gassing?

To effectively address IAQ, it all starts with the system. If the HVAC unit is not sized correctly and equipped with the proper controls, it is impossible to maintain proper IAQ over the long-term. Some air cleaners are highly effective at particle removal, while others are not. The overall effectiveness of an air cleaner depends on how well it collects pollutants from indoor air (typically stated as a percent efficient) and how much air it draws through the cleaning or filtering element (stated in cubic feet per minute). A very efficient collector with low air circulation rate will not be effective, nor will a cleaner with a high air circulation but a less efficient collector.

On the positive side, the Internet of Things (IOT) and the emergence of IAQ sensors are making things easier. IAQ sensors work by detecting volatile organic compounds (VOCs) and odors. By measuring the total volatile organic compounds (TVOC) and applying it to a rating scale, these sensors provide the data needed by connected systems to track, analyze, and clean air in the ambient environment. The sensor chips are typically just a few millimeters in width and can easily fit within the existing electronics of exhaust fans, air filtration systems, and HVAC systems. This technology is enabling air purifiers that collect pollutants, eliminate airborne allergens, mold, bacteria, viruses and volatile organic compounds. The patented technologies that are becoming commercially available today will truly change the IAQ landscape of tomorrow.

Before I end this my inaugural “Tech Talk” column, let me leave you with a shameless plug. As part of my duties with INDA, I am currently leading an initiative, along with a committee of industry experts, to raise awareness on IAQ and the roll that filtration can and will play going forward. This initiative is in the early stages of development, but if you would like more information and details on how to get involved, please reach out. My contact details are below.

Chris Plotz is the director of education & technical affairs at INDA, Association of the Nonwoven Fabrics Industry. Plotz is a business leader with 19 years of technical nonwovens- and filtration-related experience in global product management and product development within leading manufacturers including Parker Hannifin, ITW Pro Brands, and BHA Technologies, Inc. Most recently, Plotz was the director of innovation with The Green Edge, management consultants, where he led product lifecycle activities for sanitizing technologies. Chris can be reached at cplotz@inda.org or 919 459-3748.