In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Matt Migliore at mmigliore@inda.media.

Most recent update: September 30, 2020

Fitesa acquires Fiber Dynamics

Fitesa has acquired the assets of Fiber Dynamics Inc., (FDI) a producer of engineered nonwovens. Located in High Point, North Carolina, FDI manufactures meltblown and carded nonwovens for disinfectant wipes, filtration, facemasks, automotive, medical, hygiene and other industrial applications.

This is Fitesa’s third acquisition in 2020. In February, the company acquired Freudenberg Hygiene Brazil. In August, Fitesa announced the agreement to purchase Tredegar Personal Care, which is expected to close during the fourth quarter of 2020.

Source: fitesa.com

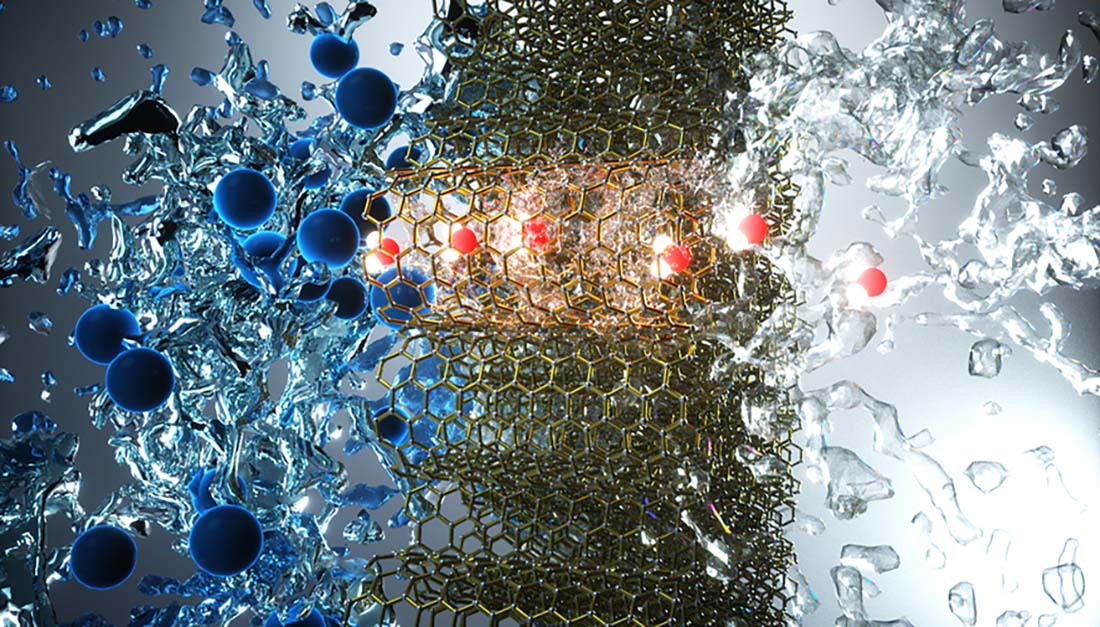

Researchers develop carbon nanotube porins to enhance performance of CNTs in desalination

Researchers at Lawrence Livermore National Laboratory (LLNL) have created carbon nanotube (CNT) pores which – at just 0.8nm – are so efficient at removing salt from water that they are comparable to commercial desalination membranes.

As the dominant technology for removing salt from water, reverse osmosis uses thin-film composite (TFC) membranes to separate water from the ions present in saline feed streams butsome fundamental performance issues remain.

TFC membranes, however, are constrained by permeability-selectivity trade-offs and often have insufficient rejection of some ions and trace micropollutants, requiring additional purification stages that increase energy usage and cost.

Biological water channels, also known as aquaporins, provide a blueprint for the structures that could offer increased performance. They have an extremely narrow inner pore that squeezes water down to a single-file configuration that enables extremely high water permeability, with transport rates exceeding a billion water molecules per second through each pore.

The team has developed CNT porins (CNTPs) – short segments of CNTs that self-insert into biomimetic membranes –which form artificial water channels that mimic aquaporin channel functionality and the intrachannel single-file water arrangement. Water and chloride ion transport was measured through 0.8-nm-diameter CNTPs using fluorescence-based assays. Computer simulations and experiments using CNT pores in lipid membranes demonstrated the mechanism for enhanced flow and strong ion rejection through the inner channels of carbon nanotubes.

Read the full story: https://www.llnl.gov/news/going-flow-water-purification

Source: https://www.llnl.gov/

Analysis shows 50M Americans have experienced dangerous air quality due to wildfires this year

An analysis of U.S. Environmental Protection Agency air quality data by National Public Radio looked at U.S. air quality on days from July to January of each year, specifically focusing on small inhalable particles that can lodge deep in the lungs and be harmful to humans. An EPA spokesperson said this kind of pollutant, known as PM2.5, is the most likely culprit found in the air from wildfire smoke.

The EPA publishes data going back to 1980, though much of the earlier data is missing information about PM2.5.

The analysis found that nearly 50 million people in California, Oregon and Washington live in counties that experienced at least one day of “unhealthy” or worse air quality during wildfire season so far this year. That accounts for 1 in 7 Americans, an increase of more than 9 million people compared with 2018, the worst previous year. And the wildfire season will continue for several months.

Read the full analysis: https://www.npr.org/2020/09/23/915723316/1-in-7-americans-have-experienced-dangerous-air-quality-due-to-wildfires-this-ye

Source: npr.org

Air filter mask designed to protect dogs form wildfire smoke

The Good Air Team, an Austin-based company, announces the first air filter mask specifically designed for dogs called the K9 Mask. It is a wearable air filter mask for dogs to protect them from the short and long-term health dangers of breathing toxic air from wildfire smoke, ash, dust, smog, chemicals, pollen, allergens, ozone, and bacteria. Dog owners in an extreme air pollution crisis can now choose pure air for their dogs.

Recent wildfires across California have sparked concerns about protecting pets from the harmful effects of toxic smoke. Wildfire smoke is dangerous because it produces toxic air particles that are easily absorbed into the bloodstream when inhaled into the lungs. These toxic particles can cause immediate and long-term health problems in people and pets. Smoke inhalation can contribute to health problems including chronic obstructive pulmonary disease, lung cancer, and vision problems.

The Good Air Team is solving the problem of extreme air pollution by providing dogs with an alternative to poor air quality. The K9 Mask is specifically designed for the shape of a dog’s muzzle. Each K9 Mask size has adjustable neck and muzzle straps to fit various size dog breeds. The replaceable air filters used in the K9 Mask have four-layers of air filtration to purify inhaled air. The filters are able to protect dogs using the CDC (U.S. Center for Disease Control) standards for toxic air filtration by using N95 (95% filtration of all non-oil-based air pollutants) with PM2.5 (particulate matter that is less than 2.5 microns in diameter) and activated carbon for absorbing toxic chemical particles.

Source: k9mask.com

EDANA to offer online version of its filtration training course

EDANA’s “Fundamentals in Filtration” will be offered in four sessions to take place on four consecutive days, from 16–19 Nov. 2020.

The training course will provide an overview of all aspects of nonwoven filter media, including filtration principles, processes and applications.

The course will start with an overview of nonwoven raw materials and technologies, with special emphasis on those techniques that are especially useful in the various filtration domains. Next the basic filtration theory will be presented, followed by a more specific explanation about air filtration, air pollution control, and liquid filtration. After a comprehensive review of filtration standards, the course is concluded by a session about converting technologies.

Lean more about this training opportunity here.

Source: edana.org

Evonik, Siemens partner to utilize CO2 & water for climate-friendly chemical production

Evonik and Siemens Energy today commissioned a pilot plant sponsored by the German Federal Ministry of Education and Research (BMBF) that uses carbon dioxide and water to produce chemicals. The necessary energy is supplied by electricity from renewable sources. The pilot plant is located in Marl, in the northern Ruhr area, and its innovative technology of artificial photosynthesis should contribute to the success of the energy revolution. It is an essential part of the Rheticus I and II research projects, which are sponsored by the Federal Ministry of Education and Research (BMBF) with a total of 6.3 million euros.

German Federal Minister of Education and Research Anja Karliczek said on the opening ceremony in Marl, “I am delighted that we have today given the go-ahead for a new test facility of the very highest standard in Marl. With Rheticus, we are showing how we can set up climate-friendly production processes in the chemical industry and at the same time manufacture new innovative products. And this works not only here in Germany, but potentially all over the world. This opens promising opportunities for technology exports. We want to promote effective climate protection and continue to have a strong industrial base in Germany. I am firmly convinced that we can succeed in both. I am pleased that my ministry is now investing a total of 6.3 million euros in the new pilot plant in Marl with this goal in mind and wish all those involved every success.“

Source: corporate.evonik.com

Source: siemens-energy.com

MANN+HUMMEL acquires helsa Functional Coating, strengthens activated carbon position

MANN+HUMMEL group today announced the completion of the takeover of helsa Functional Coating on September 21st, 2020. This business unit of the helsa group, founded in 1947, complements MANN+HUMMEL’s portfolio particularly in the area of elastomer and activated carbon technology for special industrial applications. No information concerning the purchase price has been disclosed.

“The takeover will enable MANN+HUMMEL to position itself as a technology leader in this growth market and further set the company up for the future. This is a further step towards achieving our vision ‘Leadership in filtration’”, explained Emese Weissenbacher, Executive Vice President and CFO. “The helsa Functional Coating division has a similar corporate culture since it belonged to a family business also with a long history. We are very much looking forward to working with our new colleagues.”

“For us, as a niche provider of intelligent premium solutions in molecular air filtration, the takeover holds great potential,” said Norbert Gregor, CEO of helsa Functional Coating and future Vice President & Managing Director Molecular Filtration at MANN+HUMMEL. “MANN+HUMMEL’s global infrastructure will enable us to accelerate our growth trajectory and step up our efforts in large-scale projects to reduce molecular emissions worldwide.”

Source: mann-hummel.com

Argonne National Lab to highlight breakthroughs in water purification during ‘Frontiers in Materials Manufacturing’ webinar program

Scientists at the U.S. Department of Energy’s Argonne National Laboratory will review recent breakthroughs in technologies that can deliver next-generation water purification materials during an Oct. 2 webinar program, titled “Materials for Water.”

Part of the department’s “Frontiers in Materials Manufacturing” webinar series, the “Materials for Water” webinar will focus on how manufacturing innovations figure significantly into solving the global water crisis and how pioneering technologies can deliver next-generation purification materials.

The webinar includes a virtual tour of Argonne’s newly expanded Materials Engineering Research Facility (MERF), a one-of-a-kind scale-up R&D facility enabling accelerated materials scale-up and process development through advanced materials synthesis and processing technologies, in situ/operando characterization, and advanced computing. Hear from these experts:

- Frank Cassou, Co-Founder & CEO, Cyclopure

- Peter Fiske, Executive Director, National Alliance for Water Innovation

- Alaina Harkness, Executive Director, Current

- Melissa Klembara, Technology Manager for the RAPID Institute and the Energy-Water Desalination Hub, U.S. Department of Energy

- Katie Kollhoff, Co-Founder & CEP, NUMiX Materials

- Paul Westerhoff, Regents Professor in the School of Sustainable Engineering and the Built Environment, Arizona State University

- Jeffrey Wilbur, RO/NF Membrance Chemistry Manager, DuPont Water Solutions

Register for the webinar: https://web.cvent.com/event/5a9ec6ef-de53-4f20-9499-b55458859084/regProcessStep1

Source: anl.gov

DuPont Water Solutions installs largest MABR system in UK at Severn Trent’s Worcestershire wastewater treatment site

DuPont Water Solutions installed 10 OxyMem membrane aerated biofilm reactor (MABR) modules at Severn Trent’s Redditch Spernal site in Worcestershire. This central treatment plant has thus become the largest MABR in the UK, all during a period of restricted access to the site due to the COVID-19 pandemic.

The plant processes wastewater from the surrounding catchment area as well as excess biosolids from satellite plants. Consideration for future population growth and tighter ammonia consents led Severn Trent to look for improved process efficiencies.

Rather than expanding the plant, Severn Trent opted for an upgrade by converting it to an IFAS (integrated fixed film activated sludge) MABR system. DuPont OxyMem MABR modules were simply lowered into the existing anoxic zone on site, over a two-day period, to boost nitrification capacity of the current process. The advanced technology offers simultaneous COD and ammonia removal, with nitrification rates 2-3 times greater than MBBR technology at the design temperatures.

This full-scale installation follows an extensive 12-month pilot trial at Severn Trent’s Minworth site on the northeastern outskirts of Birmingham. There, the OxyMem system proved its value, producing sludge at just 0.13 kg TSS/kg COD applied compared to the typical 0.3 – 0.4 kg of TSS/kg COD applied for activated sludge. Energy consumption was low and the aeration efficiency was 4.5 kg O2/kWh, two to three times more efficient than conventional technologies.

Source: dupont.com

Micronics Engineered Filtration Group names Glenn Hollis Chief Financial Officer

The Micronics Engineered Filtration Group announced Glenn Hollis has joined its team as the Chief Financial Officer (CFO). Effective immediately, Glenn will have responsibility for Micronics’ global Accounting, Finance, Human Resources, and IT teams, who will now report directly to Glenn.

“I am very pleased to welcome a proven veteran like Glenn to Micronics’ leadership team. Glenn brings a strong track record of success in global manufacturing companies to Micronics. He is both a hands-on leader and a strong strategic thinker, and I believe his capabilities will complement and enhance our terrific Micronics team as we continue to improve in all aspects of the business to better and more nimbly serve our diverse global customer base,” said Chris Cummins, Micronics’ President and CEO.

Glenn is based out of Micronics’ new Chattanooga headquarters, where the company’s U.S. filter media manufacturing is also located. The company additionally has operations in Dover, NH, Saltillo, Mexico, Stoke-on-Trent, UK, and in Chicago, IL.

Glenn received his bachelor’s degree in Accounting at the University of Kentucky (Lexington) and is affiliated with the Tennessee Society of CPAs and the American Institute of Certified Public Accountants.

Source: micronicsinc.com

Evoqua acquires Aquapure Technologies

Evoqua Water Technologies (NYSE: AQUA), a provider of critical water treatment solutions, has acquired privately held Aquapure Technologies of Cincinnati, Ohio, a water service and equipment company. This acquisition is expected to strengthen Evoqua’s service capabilities in Cincinnati and the surrounding region. Terms of the deal were not disclosed.

Aquapure Technologies serves the commercial and light industrial markets from its Hamilton-based branch. It provides its customers with a variety of water treatment products and services, including deionization, reverse osmosis, softeners and filtration systems.

“We are delighted to welcome Aquapure to the Evoqua family,” said Evoqua Chief Executive Officer, Ron Keating. “For over 30 years, Aquapure Technologies has been very successful by delivering excellent customer service and building a reputation as a trusted partner.”

Source: evoqua.com

Researchers leverage polymer membrane with activated carbon to remove hormone pollutants from drinking water

Supplying people with clean water is one of the biggest challenges of the 21st century worldwide. Often, drinking water is contaminated with micropollutants. Among them are steroid hormones that are used as medical substances and contraceptives. Their concentration in one liter water, into which treated wastewater is fed, may be a few nanograms only, but this small amount may already damage human health and affect the environment. Due to the low concentration and small size of the molecules, steroid hormones not only are difficult to detect, but also difficult to remove. Conventional sewage treatment technologies are not sufficient.

Professor Andrea Iris Schäfer, Head of KIT’s Institute for Advanced Membrane Technology (IAMT), and her team have now developed an innovative method for the quick and energy-efficient elimination of steroid hormones from wastewater. Their technology combines a polymer membrane with activated carbon.

“First, water is pressed through a semipermeable membrane that eliminates larger impurities and microorganisms,” said Schäfer. “Then, water flows through the layer of carbon particles behind, which bind the hormone molecules.” At IAMT, researchers have further developed and improved this process together with filter manufacturer Blücher GmbH, Erkrath. Colleagues at KIT’s Institute of Functional Interfaces (IFG), Institute for Applied Materials (IAM), and the Karlsruhe Nano Micro Facility (KNMF) supported this further development by characterizing the material. This is reported by the scientists in the journal Water Research.

Read the full story: https://www.kit.edu/kit/english/pi_2020_new-process-for-efficient-removal-of-steroid-hormones-from-water.php

Source: https://www.kit.edu/

SUEZ’s ZeeLung selected for ‘world’s largest project of its kind’ in Canada

The Region of Waterloo has selected SUEZ’s ZeeLung technology to equip what will be the largest Membrane Aerated Biofilm Reactor (MABR) system in the world at the Hespeler Wastewater Treatment Plant, in Ontario. The innovative technology will support the regional government’s objectives to deliver better water quality while improving nutrient removal, reducing energy and maximizing the treatment capacity and performance from existing assets.

“This is a first-of-its-kind project for Canada that will demonstrate ZeeLung’s benefits: the ability to quickly and easily upgrade existing wastewater treatment plants on a cost-effective basis, with little disruption to on-going operations,” said Kevin Cassidy, executive vice president engineered systems for SUEZ – Water Technologies & Solutions. “The technology allows customers to increase the treatment capacity of their plants, for a better water quality in a compact footprint while also reducing energy consumption.”

ZeeLung technology is used to upgrade conventional activated sludge plants for nutrient removal and capacity expansion. ZeeLung employs a gas permeable media to deliver oxygen to a biofilm that is attached to the media surface. Oxygen is delivered through the media by molecular diffusion, which is done without the use of bubbles. In conventional wastewater treatment, 60% of the energy used is consumed by blowers that deliver bubbles to provide the oxygen necessary for the biological process. With ZeeLung technology, oxygen is delivered without bubbles, which reduces the energy required for oxygen transfer by up to 4-times. This allows plants to significantly reduce their energy footprint while also increasing capacity and improving treatment quality.

The Region of Waterloo, in southwestern Ontario serves a total population of more than 600,000 people using its 13 wastewater treatment plants to process 180 million litres of wastewater per day. To meet the projected population growth, the secondary treatment process of the Hespeler plant has to be upgraded. The new contract follows an 8-month pilot which demonstrated the ZeeLung technology and refined the design for full-scale implementation.

When commissioned in 2021, the 9.34 MLD upgrade will be the largest implementation of MABR technology in the world.

Source: suezwatertechnologies.com

Joseph Cotruvo earns 2020 environmental health award from NSF International and NEHA

NSF International and the National Environmental Health Association (NEHA) announced Joseph Cotruvo, Ph.D., BCES, as the winner of the 2020 Walter F. Snyder Environmental Health Award. Dr. Cotruvo received the award at the virtual 2020 NEHA Annual Education Conference, in recognition of more than 45 years of dedicated service to environmental and public health through leadership, collaboration, and consensus national standard development. Dr. Cotruvo’s accomplishments as a “clean water crusader” include 23 years as Director of the U.S. EPA’s Criteria and Standards Division in the Office of Drinking Water, and as Director of the Risk Assessment Division in Toxic Chemicals. He also worked four years at NSF International, first as a Senior Regulatory Executive and later as Vice President of Environmental Health Sciences, where he helped to advance the NSF/WHO Collaborating Center for Drinking Water. He later established the professional environmental consulting firm Joseph Cotruvo & Associates.

Dr. Cotruvo chairs the American Academy of Environmental Engineers and Scientists’ Excellence in Environmental Engineering and Science Award committee. He’s an Albert Nelson Marquis Lifetime Achievement honoree and past President of the Inter-American Association of Environmental and Sanitation Engineering. He has served as associate editor and, later, on the editorial board of the American Water Works Association’s Journal AWWA. Dr. Cotruvo is an Adjunct Professor in the Departments of Chemistry and Environmental Sciences at the University of Toledo.

Dr. Cotruvo is a board-certified member of the American Academy of Environmental Engineers and Scientists and an honorary life member of both the American Water Works Association and the Water Quality Association. He is also a member of the American Chemical Society, the International Dose-Response Society, and the Senior Executives Association.

For nearly 50 years, NSF International and NEHA have presented the Snyder Award to recognize public health professionals who safeguard air, water, food, and the environment. The Snyder Award honors NSF International’s co-founder and first executive director, Walter F. Snyder, who provided contributions to the advancement of environmental and public health.

US EPA, DoD & state partners launch PFAS innovation challenge program

At a per- and polyfluoroalkyl substances (PFAS) roundtable hosted by U.S. Congressman Richard Hudson (NC-08) in Fayetteville, N.C., U.S. Environmental Protection Agency (EPA) Administrator, Andrew Wheeler, launched an innovation challenge to identify solutions to destroy PFAS.

The Innovative Ways to Destroy PFAS Challenge is a partnership between federal and states agencies seeking detailed plans for a non-thermal technologies to destroy PFAS in concentrated aqueous film forming foam (AFFF), a type of firefighting foam. This challenge is part of the significant progress the EPA has made in implementing its PFAS Action Plan.

To address the need for new non-thermal technologies that destroy PFAS, without generating hazardous byproducts, EPA is offering up to $50K for the best design concept(s), with the added potential opportunity for field testing of the winning design concept(s) in partnership with EPA and ESTCP. Challenge details can be found at: https://www.epa.gov/innovation/innovative-ways-destroy-pfas-challenge. The challenge closes on November 23, 2020. Winners are expected to be announced in early 2021.

Source: epa.gov