The adoption of state-of-the-art filtration systems can work to reduce carbon emissions from aircraft, improve safety and comfort for passengers and ultimately support the aviation industry in meeting its environmental goals.

The coronavirus pandemic will stay front and center in our collective mind for years to come, and so will the memories of one of its most notable characteristics – empty airport terminals as international borders closed, and domestic travel was significantly curtailed.

Aviation has been one of the worst affected industries as restrictions over the last year have inhibited cross-border travel and aircraft have sat dormant on the ground. As a driving force in our fast-paced, connected world, the re-starting of the industry should be a priority, but we also should not lose sight of the positive environmental benefits that have come about as a result of restricted travel.

Aviation emissions decreased by 60% when countries were in maximum lockdown phases and domestic flights were grounded.1 How can the industry restart while continuing to protect the environment as best as possible?

The good news is the European aviation industry has already committed to lowering its environmental impact. Despite being responsible for just 2.5% of annual CO2 emissions, it has a lofty goal of net zero emissions by 2050. That’s why the next generation of ultra-efficient, low-carbon aircraft will exceed current emissions legislation.

Reducing carbon emissions through filtration technology

Central to meeting this commitment is the adoption of state-of-the-art filtration technologies, which are being incorporated into aircraft to reduce carbon emissions and are working to change the aerospace industry for the better. These technologies are being introduced through initiatives including the Clean Sky 2 Joint Undertaking (CSJU) which is a public-private partnership between the European Commission and the European aeronautics industry working to meet the industry’s target of climate neutrality.

At Pall we are actively involved in this initiative through our work to integrate innovative filtration technologies into aircraft to cut fuel burn and reduce emissions. Overall, the CSJU is committed to reducing fuel and CO2 by 75% per passenger kilometer, nitrogen oxide by 90% and perceived noise by 65% by 2035.

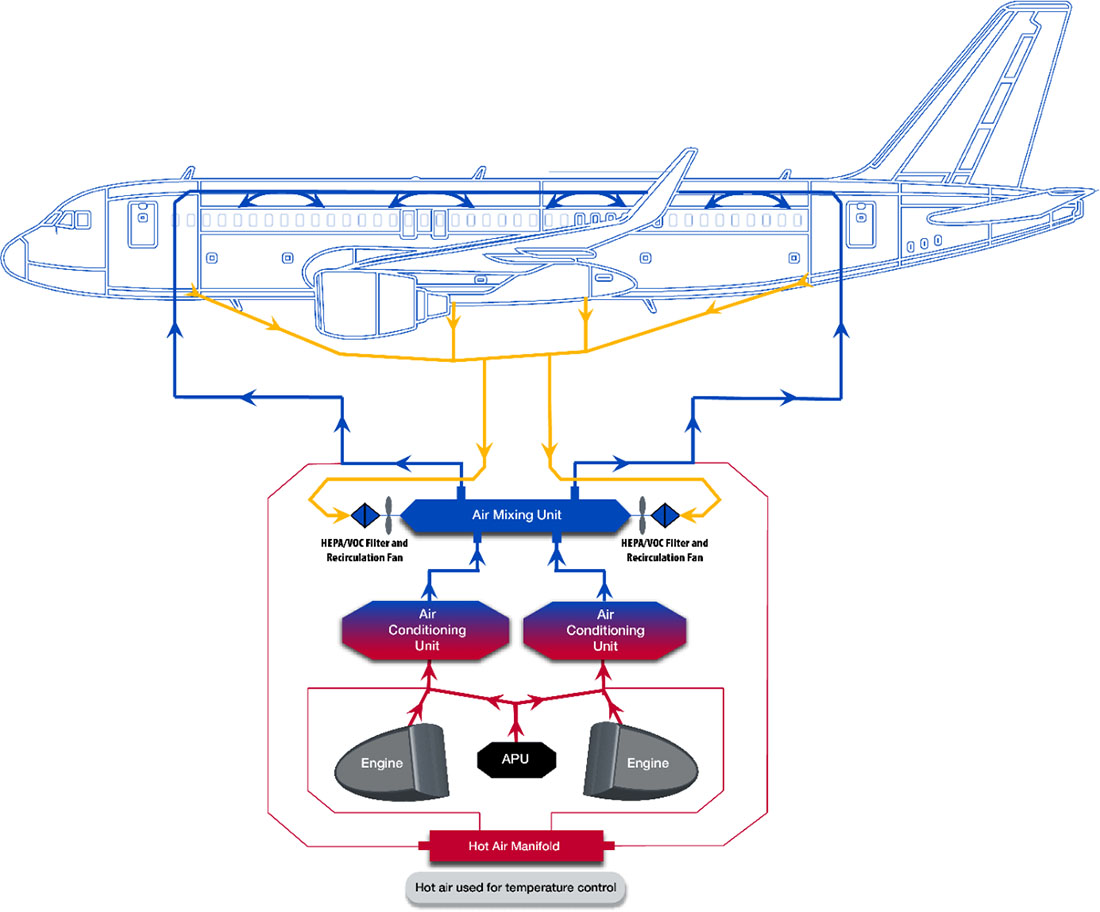

There are two core pieces of technology that have the potential to significantly impact carbon emissions of aircraft – Adaptive Environmental Control Systems and Aircraft Engine Inlet Protection. As part of the same project, Pall is also working on the next generation of Cabin Air Recirculation Filters to make overall air travel safer.

A breath of fresh air

Adaptive Environmental Control Systems (AECS) can continually monitor air quality in a cabin and adjust the fresh air flow accordingly to ensure a constant source of clean air while optimizing fuel economy. This can enable an aircraft to reduce the amount of fuel used to power the ECS to just 3% – from the standard 5% – thanks to a 40% reduction in the amount of bleed air required.

This can result in transatlantic flight fuel burn being reduced by up to 2,000 kg, as taking bleed air from the engine results in a reduction of thrust capability and additionally, avoids energy waste in the act of air compression for the cabin air supply, and subsequent decompression of the cabin.

This also has a significant economic impact. As fuel constitutes up to 30% of total industry expenses, fitting all planes with AECS could have a significant cost-cutting impact. At a time when the aviation industry is suffering financially from the effects of the pandemic, this is especially important.

Protecting engine assets

There are also other significant innovations happening as part of the Clean Sky 2 project that will support carbon emission goals. Pall is contributing to the development of the tilt rotor integrated air intake and engine protection system (TRIcEPS) through a vortex tube filtration technical demonstrator. A removable thermoelectric ice protection system, based on heater layer technology, can be used on the wings of aircraft to reduce icing while a vortex tube filter can protect the engine from particles in harsh environments.

The successful completion of the TRIcEPS technical demonstrator will have a positive environmental impact by ensuring engine protection in tough environments, allowing aircraft to fly more direct and land closer to the end destination not dependent or being limited by previously considered optimal landing sites.

Protecting the environment post-pandemic

Beyond reducing carbon impact, filtration has another crucial role. There is increasing investment and innovation at Pall in Cabin Air Recirculation Filters, which work to help reduce the spread of infectious agents in the cabin such as SARS/coronavirus. Combining HEPA filtration with High Performance Activated Carbon (HPAC) and other innovative solutions such as hybrid photocatalytic air filters enables the removal of other pollutants and odors.

The adoption of state-of-the-art filtration systems can work to reduce carbon emissions from aircraft, improve safety and comfort for passengers and ultimately support the aviation industry in meeting its environmental goals.

References

- “Temporary reduction in daily global CO2 emissions during the COVID-19 forced confinement,” Nature, May 19, 2020, https://www.nature.com/articles/s41558-020-0797-x.

![Figure 1: Heat Exchanger Proventics GMBH.[22]](https://www.filtnews.com/wp-content/uploads/IFN_2_2024_crimpedmicrofiberyarns_Fig.-1-Heat-exchanger-225x125.jpg)