The American Filtration & Separations Society marked its 32nd anniversary with the presentation of its FiltCon 2019 conference April 1-3 in Cherry Hill, New Jersey. The event featured short courses, technical sessions in four tracks, six plenary presentations and an expo. Leveraging subject matter experts from academia and commercial backgrounds, FiltCon touched on a wide range of topics related to industrial, air, gas, and liquid filtration.

Advances in nanofiber filtration schemes

Following short courses on day one of FiltCon, the conference program kicked off with a plenary session by professor Wallace Leung of The Hong Kong Polytechnic University. Leung discussed the role of nanofiber technology in enabling efficiencies in what he describes as the three core areas of impact for filtration going forward: Energy, Health and Environment.

Among the world’s leading researchers in the area of nanofiber filtration, Leung touched on several new developments, including the use of layered nanofibers, microfiber-nanofiber composites, and photocatalytic graphene-infused nanofibers.

Leung said new technology leveraging a layered (i.e., multilayer) nanofiber has shown to minimize pressure drop in facemask filtration applications. While nanofibers offer very high filtration efficiency, this efficiency is accompanied by an adverse high pressure drop. By employing a multilayer design separated by permeable support, Leung said it is possible to achieve high filtration efficiency with lower pressure drop than traditional single-layer nanofiber facemasks. In road tests in Hong Kong, Leung said the multilayer nanofiber achieved at least 75 percent capture efficiency for nanoaerosols for people at rest and 60 percent for people engaging in heavy activities. Meanwhile, pressure drop was reduced by up to 30 percent.

Leung also discussed the use of electrostatically charged nanofibers to induce dipoles on neutrally charged aerosols to capture airborne viruses by electrostatic force. He said this technology is particularly advantageous during a flu virus outbreak, as it is able to enhance filtration efficiency without added pressure drop. Further, he said solutions with microfibers upstream of nanofibers in a composite system have proved to be effective for long-term heavy aerosol loading. The microfiber-nanofiber composite provides excellent capture of nanoaerosols from initial filtration (due to downstream nanofiber layer) to subsequent surface/cake filtration (due to upstream microfiber layer). Leung said microfiber-nanofiber composite filters are well suited for applications in transportation, hospitals, offices, and auditoriums.

Another development Leung highlighted during his presentation focused on the use of graphene-infused nanofibers to improve filtration efficiency. Citing new technology, which employs photocatalysts working synergistically to harvest light-producing radicals, Leung explained that graphene helps optimize electron transfer to produce needed radicals along the nanofiber to enable photocatalytic oxidation of gaseous pollutants, viruses and bacteria. For NOx and formaldehyde, specifically, Leung said graphene-infused nanofiber outperforms currently available technologies by seven times and three times, respectively.

Advancements in high-purity filtration membrane media

Don Largent, the high-purity filtration product manager for AAF Flanders, used his plenary session to cite a series of megatrends that he believes will drive the filtration industry in the coming years.

Largent said with more than 7 billion people predicted to be living in cities around the world by 2050, air pollution will continue to be a pressing concern. Currently, 92 percent of the world’s population is living in areas where World Health Organization Air Quality Guidelines are not met. Urbanization will compound this issue, and this trend will present opportunities for new and existing filtration technologies.

At the same time, Largent said the continued rise of the middle class will also drive demand for filtration. According to the National Intelligence Council’s “Global Trends 2030” report, the growth of the middle class “constitutes a tectonic shift – for the first time a majority of the world’s population will not be impoverished.” In addition, Largent noted that 70 percent of middle class spending will be in Asia by 2050.

With the rise of the middle class, Largent said tremendous pressure will be put on resources. By 2030, studies predict demand for food will increase by 35 percent, demand for water will increase by 40 percent, and demand for power will increase by 50 percent. To meet these needs, Largent said filtration systems will have to play a key role.

Big Data is another megatrend Largent believes will have a significant impact in filtration. As of 2018, Largent noted that there were 15 billion large manufactured objects in the world, and less than 2 percent of those were connected to a network system. However, with Industry 4.0 gaining momentum, more than 50 billion devices are expected to be connected by 2020. With this increase in connectivity comes increased transparency in a wide range of environments, and Largent said this will have an impact in filtration as the “invisible becomes visible,” performance requirements increase, and tougher legislation opens the door for a significant increase in new applications and technology development.

Largent said the megatrends of urbanization, a growing global middle class, and Big Data, ultimately lead to what he sees as the fourth filtration megatrend – indoor air quality science & awareness.

Citing the WHO, Largent said air pollution is estimated to cause 7 million deaths per year. With urbanization and a growing middle class putting added pressure on air quality and resources and Big Data making the invisible visible, people will begin to make the connection between health and resource concerns and the need for filtration systems. This, Largent predicts, will lead to a boom in filtration demand and huge increases in investment in filtration technology.

Gas cleaning in demanding applications

Professor Achim Dittler, Ph.D., of the Karlsruher Institut fur Technologie, presented a plenary session on gas filtration, which focused on the separation of particulate matter from gas streams.

Dr. Dittler noted that while filter media are characterized under distinct laboratory conditions according to given standard test procedures, they are applied under operating conditions, which are often different from test conditions. Once particulate matter is reactive or gas conditions become humid or reactive, he said the operational behavior of the filter may change significantly.

For example, he cited depth filters, which are used in air-conditioning systems, cleanrooms, and exhaust gas treatment. Particles are separated inside a porous structure. While detachment of separated particles and stepwise transportation does not happen in most applications, reactive components in deposited particle structures can cause rearrangement and detachment. Likewise, he said gas reactions due to solubility conditions can impact filtration performance, such as in costal conditions.

Dittler said a full understanding of operating conditions is required to predict the performance of a filter media in a given environment, particularly in gas filtration scenarios. More details about the research Dr. Dittler and the Karlsruher Institut fur Technologie are conducting in the area of gas cleaning in demanding applications can be found at mvm.kit.edu.

Gaining an advantage in a competitive market

Charles Vaillant, chief technology officer for Mann+Hummel, presented a session on the keys to successful innovation in a competitive marketplace. As Mann+Hummel strives to differentiate itself, Vaillant said the company is focusing on three specific areas: E-Mobility, Digitalization and Sustainability. From an execution perspective, Vaillant said there are three tactics Mann+Hummel relies upon to achieve its goals: Customer Obsession, Speed and Innovation.

By understanding how customers use products in their actual habitat and leveraging data gathered during the use of its products in live applications, Vaillant said Mann+Hummel is able to design solutions to meet the unique needs of very specific customer sets. “We do not farm in ISO dust,” said Vaillant. “We farm in snow and rain and different conditions.”

On the e-mobility front, Vaillant said Mann+Hummel sees hybridization as a game changer, with cars becoming smaller, lighter and more efficient. Likewise, he said the cars of the future will become office spaces and living rooms, and the standard for filtration and cabin air quality will need to improve to meet the requirements of these different uses.

“The vehicle will drastically change, and you see OEMs working on how the interior of cars will function in the future,” said Vaillant.

Vaillant said he often asks customers, “What is the best filter we can provide?” A question to which one customer replied, “Charles, the best filter you can provide is one that doesn’t exist.”

Vaillant said this concept of nonexistence is behind Mann+Hummel’s Senzit digital monitoring tool. Senzit uses sensors to monitor air filter status in agriculture, construction and mining machinery, gauging filter load status, remaining filter lifetime, and machine hours worked. Senzit measures the condition of the air filter and transfers the data to a user’s mobile device or the fleet manager’s desktop. Thus, a manual check of the filter is not necessary. This allows the user to plan maintenance times in advance and in combination with other maintenance activities, increasing machine uptime, protecting the vehicle engine, and preventing unnecessary filter changes.

Ultimately, Vaillant said customers want simplicity. “Don’t confuse me, make it simple, make it easy, make my costs low,” are common mantras from the customer side, according to Vaillant.

In terms of sustainability, Vaillant said innovation in filtration will be dictated in large part by public policy. “People have a voice today in a way they did not in the past,” said Vaillant. And this voice will increasingly bring environmental and sustainability concerns to the forefront, which Vaillant said will naturally shine a light on innovative filtration systems.

Membrane advances

Peter Cartwright of Cartwright Consulting Co., LLC, presented a session on emerging technology for membrane treatment. He said while the crossflow, pressure-driven membrane separation technologies of microfiltration, ultrafiltration, nanofiltration and reverse osmosis have been lynchpin processes in water and wastewater treatment for over 75 years, incremental improvement is happening, and much time and effort is being expended to develop radically new products with superior performance and enhanced application efficiency. Cartwright highlighted three specific membrane technologies that have advanced beyond the laboratory stage.

Nanoporous Graphene Membranes

Citing the work of assistant professor, Piran Kidambi, Ph.D., of the Vanderbilt School of Engineering, Cartwright discussed the use of graphene for Nanoporous Atomically Thin Membranes (NATMs). NATMs are two-dimensional, one carbon atom thick membranes that feature a hexagonal lattice construction. Cartwright explained how Dr. Kidambi has used graphene NATMs to produce “several order of magnitude” higher flux than existing RO membranes by removing contaminants via molecular sieving.

For example, studies showed hydroxylated and hydrogenated graphene NATMs produced virtually 100 percent salt rejection with a water permeability of nearly 100 L/cm2/day/MPa, while the highest performing RO membranes generated less than 1 L/cm2/day/MPa water permeability at approximately the same salt rejection rate.

While the early performance results are compelling, Cartwright said graphene does have some shortcomings, including that it is difficult to fabricate and that it is hydrophobic. He also noted, importantly, that graphene membrane technology has yet to be commercialized, so there is a lack of real-world application data.

Forward Osmosis

Cartwright highlighted forward osmosis (FO), noting that while it has not displaced RO membrane technology in the way some had predicted when it was first introduced, it has a valuable role to play in certain filtration applications.

Cartwright said FO offers some compelling advantages, such as a resistance to fouling, no power requirement, and the ability to support chlorine tolerant membranes. However, these advantages come with one important disadvantage, i.e., significantly lower flux rate than RO systems. RO systems operate in the range of 400-1,100 PSI, while FO systems operate in the range of 25 PSI. That said, Cartwright pointed out that FO systems offer power savings of about 30 percent compared to RO systems, with a comparable capital cost.

Cartwright said hollow-fiber FO membranes are well suited for low viscosity liquids where a high packing density and low footprint are required; tubular FO membranes are suited for highly viscous liquids, where ease of cleaning and installation are important; and spiral wound FO membranes are suited for liquids with medium viscosity, where standard module configurations are desirable.

Biomimetic Membranes

Cartwright cited biomimetic membrane technology from a new company called Aquaporin (Kongens Lyngby, Denmark) as a compelling advance for the filtration industry. The technology mimics the aquaporin protein molecule and facilitates water passage. Aquaporin water channels are nature’s water filters and can be found in all living cells – from bacteria to plants to humans. Aquaporin water channels only allow water (H2O) to pass through the channel, while blocking all other present impurities, regardless of their molecular weight. Each aquaporin water channel can transport up to one billion water molecules per second.

Aquaporin (the company) leverages aquaporin proteins to facilitate filtration functions within all of its products. By incorporating aquaporins into RO membranes, Cartwright said it is possible to give a membrane the same unique properties as in nature, allowing the membrane to achieve up to 50 percent higher water flow. Cartwright said this technology is ideal for water treatment in remote areas where water pressure is low or where water purifiers are operating without a pump.

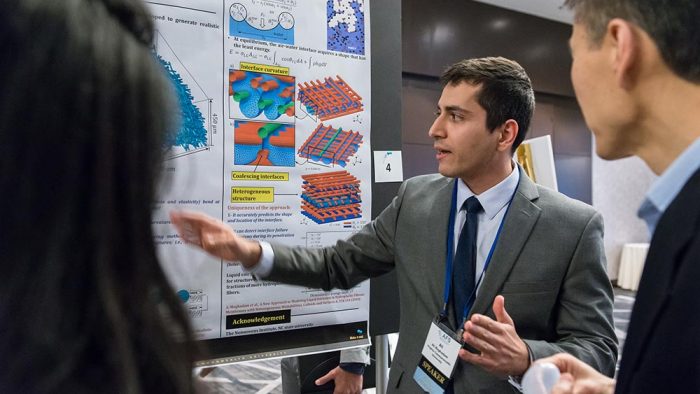

Poster presentations

FiltCon featured poster presentations by students from universities worldwide. A panel of judges reviewed the posters during the conference, and awards were issued for first, second and third place.

First place went to Mohammad Jamali of Virginia Commonwealth University for his poster, titled “Droplet Adhesion to Hydrophobic Nonwoven Fibrous Surfaces.” The poster featured computational and experimental data on droplet mobility over hydrophobic nonwoven materials (electrospun Polystyrene in this case). As the Earth’s gravity is not strong enough to detach water droplets from the fibers, the experiments were conducted using an aqueous ferrofluid, and the ferrofluid droplets were mobilized on the surface with the help of a permanent magnet. The detachment process was recorded via a high-speed camera to detect the moment of detachment, and the magnetic force was measured using a sensitive scale. Numerical simulations were also conducted to help develop an easy-to-use predictive equation for the force required for droplet detachment from the nonwoven surface.

Second place went to Harshal Gade of the University of Akron, Ohio, for his poster, titled “Faraday Bucket Measurement of Charged Pvdf Nanofibers.” The poster featured electrospun polymeric nanofibers, three-dimensional porous structures with high surface-to-volume ratio. According to the poster, electrospun fibers, depending on the polymer material, may inherently exhibit stored electrical charges. There are a number of techniques reported in literature for inducing charges into fiber mats. One common issue is measurement of the amount of charge in a fiber mat. In this poster, a custom-made Faraday bucket was described for measurement of the charge on the fiber mat. The poster discussed experimental challenges to achieve consistent, reproducible charge measurements. Measurements of PVDF samples were compared to charges on other common fiber materials. The poster explained how applications of the Faraday bucket were employed in experiments to (1) assess methods for storing charged fiber mats and (2) evaluate the decay rate of charged fiber mats.

There were two third place winners: Emrah Sozumert, Loughborough University, Leicestershire, UK, for his poster titled “Developing 3D Fully Parametric Multi-Scale Computational Model for Nonwoven Simulations” and Sina Yousefi, Virginia Commonwealth University, for his poster, titled “Effects of Electrospinning Parameters on Microstructure of Polystyrene Fibrous Mats.”

Souzumert’s poster focused on a method to develop a 3D multi-scale, fully parametric computational model for characterizing the deformation mechanism of nonwovens. This parametric model was used for simulating deformation behavior of nonwovens under tensile and compressive loads, as well as their flow behavior under various operating conditions. The developed model accounts for 3D fibers with various cross-sections and fiber-to-fiber contacts, transmitting the force from one fiber to another. The model enables the performance of parametric investigations on fibrous networks. Depending on computational power, the poster showed how scales of models from 2 mm to gigantic 3D parametric models for macro-scale analysis can be generated, as well as the monitoring of the morphological characteristics of the nonwoven microstructure.

Yousefi’s poster on electrospinning presented a method to produce polymer fibers from a polymer solution. This poster presented a mathematical model developed to serve as a tool to simulate the 3D morphology of electrospun fibrous materials. The model is based on a mass-spring-damper representation of the fibers and allows for realistic simulation of fiber curvature at the fiber-fiber crossovers. The simulations were calibrated using experimental data obtained by electrospinning Polystyrene fibers. With the calibrated code, the effects of electrospinning condition (e.g., voltage or needle-to-collector distance) on the microstructural properties (e.g., thickness or porosity) of the resulting fibrous mats were measured.

Awards

AFS recognized five members in the categories of Senior Scientist, Junior Scientist, AFS Fellow, New Product, and Engineering Merit.

Christine Sun, Ph.D., president of Filtration Technology International, was presented an AFS Fellow award for superior contributions of organization and leadership to the society. Dr. Sun has been an AFS member since 2008, serving on the AFS board in 2010-2012, as AFS Chair in 2016-2017, and receiving the Senior Scientist award in 2012. She is currently the Operation Chair of World Filtration Congress – a conference AFS will host in 2020 – and an Education committee member and instructor for multiple AFS training courses.

Ashish Bandekar, Ph.D., an R&D engineer with Filtration Technology Corporation, received the Young Scientist award, which honors individuals at the beginning of their career who have made important contributions to the technology of filtration and separation. Dr. Bandekar completed his doctorate in chemical and bio-molecular engineering from the University of Akron. He has worked in the areas of filtration, electro-wetting and coalescence and has a patent for his work on electro-wet coalescer in liquid/liquid filtration and has published research papers in multiple journals. Bandekar has been an active member of AFS since 2013 and is currently a member of the Publication Committee and Chapter Affairs Committee for AFS.

Rahul Bharadwaj, Ph.D., received the Senior Scientist award, which honors individuals in the middle of their career who make a significant contribution to the technology of filtration and separation. Dr. Bharadwaj is applications engineering manager at Lydall Performance Materials and previously Global Product development manager at AAF Flanders. He has more than 12 years of experience in research and development in media development and filter design. His areas of expertise involve filtration, separations, filter media, nanofibers and analytical testing. He has been member of the AFS Scientific Committee and is currently an editorial advisory board for International Filtration News. Dr. Bharadwaj is vice chair of AFS and will advance to chair later this year. He is on the WFC Scientific Committee and is involved with several standards and research committees at ASHRAE and ISO. He has more than 15 publications and proceedings in the field of filtration.

Ahlstrom Munksjo won the New Product award for its Extia technology, a calendered, wet-laid nonwoven filtration media that is specifically designed for dust filtration cartridge applications for air pollution control. Extia extends filter life and effectively removes coarse particulates at a low pressure drop and is easier to convert into a filter.

Croft Filters Ltd. was awarded the Engineering Merit Award for CF Quick Release Filter. The Engineering Merit Award is a runner-up award to New Product award, in years when there are two products in close competition for the top award.

The CF Quick Release Filter (QRF), is a solution for mounting a wire mesh disc filter in-line within flexible tubing prior to static operating system elements. Croft’s QRF can filter within a short section of flexible tubing and allows for quick change of filter elements and ease of cleaning, without the need to insert more permanent housings.

Corporate sponsors

AFS named four new Corporate Sponsors at FiltCon:

- Filtration Group Corp.: With offices in 28 countries, Filtration Group is focused on providing solutions for indoor air quality, fluid filtration, life sciences and industrial technologies.

- Fujifilm North America: Fujifilm has leveraged over eight decades of photographic-film manufacturing technology into several new areas of focus, including the micro-filtration membrane market.

- MayAir Group: A manufacturer, developer and provider of air filtration equipment and clean air solutions with offices in China and Malaysia.

- Xinxiang Shengda Filtration Technique Co., Ltd.: Xinxiang Shengda Filtration Technique Co., Ltd., is engaged in designing and manufacturing filtration products since it was established in 1998.

- AFS will host its Fall Conference Sept. 25-26 in Cleveland, Ohio followed by the 13th Annual World Filtration Congress Apr. 20-24 in San Diego, Calif. For more information, visit www.afssociety.org.