In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Matt Migliore at mmigliore@inda.media.

Most recent update: December 30, 2020

Camfil expands global footprint with new state-of-the-art R&D and production facility in China

Camfil Group is expanding its operations globally, with a new state-of-the-art facility in China now under construction. This advanced facility will be one of the largest Camfil Group has in the world, built on a total area of 40,467 square meters in Taicang city, Jiangsu province, China. Construction is expected to be completed in 2021.

The Taicang facility will feature a research & development center equipped with advanced technology and the ability to design custom products for the Asia Pacific market. A new laboratory in the R&D center will enable filter testing according to ISO 16890. This facility will also include the first integrated factory for Camfil Group with four production lines: general ventilation filter, turbomachinery filter, molecular contamination control filter, and a new series for air pollution control, as well as a metal works center for housings, air cleaners, and dust collectors.

Source: camfil.com

Clarkson University’s Center for Air and Aquatic Resources Engineering and Sciences receives DoD PFAS accreditation

Clarkson University’s Center for Air and Aquatic Resources Engineering and Sciences (CAARES) Lab is now accredited to perform per- and polyfluoroalkyl substances (PFAS) analysis.

The accreditation is through the Department of Defense Environmental Laboratory Accreditation Program (DoD ELAP), which is designed to accredit laboratories that wish to test for Department of Defense environmental restoration programs.

PFAS, or Per- and Polyfluoroalkyl Substances, represent a diverse group of man-made chemical compounds that are persistent; meaning they don’t break down and can accumulate over time. According to the EPA, there is evidence that exposure to PFAS can lead to adverse human health effects. PFAS compounds have been used in hundreds of industrial applications and consumer products including carpeting, apparel, upholstery, food paper wrappings, fire-fighting foams, and metal plating.

Clarkson University has numerous research grants with the EPA and DoD investigating ways to destroy PFAS in contaminated water and soil. These promising technologies have been featured in several international publications, are undergoing field tests, and have spun-off two start-up companies, including Professor Michelle Crimi’s RemWell LLC and Professor Selma Mededovic and Professor Thomas Holsen’s DMAX Plasma LLC.

“I am fortunate to be working with talented researchers and state-of-the-art equipment in the CAARES laboratory. There are only a limited number of accredited labs in the country, and we are the only accredited university lab. This distinction will give us a significant advantage as we continue to pursue research in this area,” Professor Holsen, Co-Director of CAARES said.

CAARES has analytical facilities that house a number of major instruments, as well as laboratory space specifically designed to support research. The major types of instruments are an inductively coupled plasma-mass spectrometry (ICP-MS) system, liquid chromatography-mass spectrometery (LC-MS) systems, and gas chromatography-mass spectrometry (GC-MS) systems, including a 2-D gas chromatograph/high-resolution mass spectrometer system. The Environmental Protection Agency (EPA) and Clarkson University have funded this equipment.

Source: clarkson.edu

US stimulus package includes $82B for facility upgrades, including ventilation and filtration systems

U.S. congressional leaders have voted to approve a $900 billion COVID-19 relief package. The legislation assistance includes “back-to-school” funding of $82 billion for colleges and schools, including for heating-and-cooling system upgrades to mitigate virus transmission and reopen classrooms. The funding is significant for manufacturers of filter media and related equipment for HVAC systems in such facilities.

Read the full bill: https://www.washingtonpost.com/us-policy/interactive/2020/covid-relief-bill-full-text/

Sartorius acquires WaterSep BioSeparations LLC

The life science company Sartorius has acquired U.S.‑based purification expert WaterSep BioSeparations LLC through its subgroup Sartorius Stedim Biotech. WaterSep BioSeparations develops, manufactures and markets hollow‑fiber membrane devices and pre-sterilized assemblies for upstream and downstream biopharmaceutical applications. The privately owned company based in Marlborough, Massachusetts, employs around 15 people and is expected to earn revenue of approximately $2.5 million U.S. in 2020 at strong growth rates and a substantial double-digit EBITDA margin. The parties agreed on a purchase price of approximately $27 million U.S. plus an earn‑out component of up to $9 million U.S. , depending on the achievement of defined sales revenue growth by 2023.

Source: sartorius.com

Hollingsworth & Vose NanoWave XT filtration media wins WFI Product of the Year Award

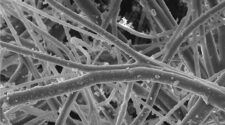

Hollingsworth & Vose, a global manufacturer of advanced materials used in products that provide clean air, clean liquids and energy storage, won Waterloo Filtration Institute’s Product of the Year Award for its standards-setting NanoWave XT filtration media.

With NanoWave XT, H&V has introduced a new filtration media for use in HVAC systems that outperforms other media – reducing exposure to hazardous fine particulates while lowering energy consumption.

H&V’s NanoWave XT is used to improve indoor air quality (IAQ) in numerous public facilities, including hospitals, schools, airports, hotels and more.

The Product of the Year award is given out annually to one new product to signal excellence in the industry. As an organization, WFI is dedicated to developing advanced filtration and separation solutions for a clean and sustainable world. WFI connects the filtration industry and academia.

NanoWave XT has the highest performance and protection against PM1 particles. It offers the best possible cost-efficiency and significant energy savings due to up to 40% lower pressure drop, which reduces CO2 emissions by 30%.

In addition to producing filtration media for HVAC systems, H&V is a leading producer of critical healthcare related materials, including filtration media for facemasks, N95 respirators, materials used in the production of ventilators, surgical hoods, and consumables for COVID-19 test systems.

Source: hollingsworth-vose.com

WFI virtual conference attracts nearly 200 attendees with a focus on IAQ & COVID-19

The Waterloo Filtration Institute’s 2020 Virtual Conference, “IAQ Health and Safety Solutions Associated with COVID-19,” was presented December 15-16. The event was attended by near 200 filtration industry professionals.

The event was moderated by Jay Forcucci, conference co-chair and vice president of Cerex Advanced Fabrics, and it featured 16 distinguished expert speakers from academia and the industry Four sessions addressed the latest developments of facemasks and air filtration in response to COVID-19:

- Emerging Challenges and Responses

- IAQ and the Built Environment

- Facemask Technologies and Latest Developments

- Facemask/Air Filter Test Methods and Standards

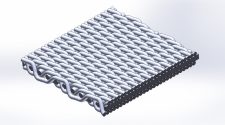

“Product of the Year Awards” were presented to Hollingsworth and Vose for its NanoWave XT filter media and Donaldson Torit for its Rugged Pleat Baghouse and Filter.

“Innovative Product of the Year Awards” were also awarded to Pure Air Filtration in the USA (FiberShield), Hangzhou Special Paper Industry Co., Ltd. In China (Akso & Hermes Multi-function loop scarf), Camfil in the USA (Durafil Compac), and IFTS in France (GLP/LEP Porometer).

“Student of The Year” was awarded to the student who had the highest score in WFI’s Certified Filtration & Separation Specialist (CFSS) 2020 program, which included 9 required courses and 8 elected courses. Kiarash Kiantaj of LMS Technology in Minneapolis, Minnesota, won this award.

Source: wfinstitute.com

NX Filtration nanofiltration membranes to serve drinking water treatment project in Indonesia

NX Filtration, specialist in innovative hollow fiber membrane solutions, was selected to supply its hollow fiber nanofiltration membranes for the optimization of the Dumai City Water Treatment Plant in Indonesia. The project, for the Ministry of Public Works and Human Settlement of the Republic of Indonesia, the World Banks’ National Urban Water Supply Program (NUWSP) and the Local Government of Dumai City, contributes to the goal of providing access to improved water sources.

The nanofiltration system for the city of Dumai, an important trade hub in the province of Riau on the island of Sumatra, will have a capacity of 50 liters per second (180m3/h), consisting of 120 NX Filtration dNF80 membrane modules. With this system, the local Masjid river can be turned into a valuable source for the supply of drinking water to the city of Dumai. This river contains high amounts of color and various pollutants, which are accumulated in the river during its flow through the rainforest.

The project was initiated by PT. Bayu Surya Bakti Konstruksi, an Indonesian specialist in constructing water and wastewater treatment plants, in collaboration with PT. Bumi Kirana Asri, Indonesia’s local distributor for NX Filtration’s products. Through a series of pilot tests, that were conducted over the past year, these parties demonstrated how the hollow fiber nanofiltration system could effectively remove color and various pollutants from the peat water, and as such form the basis for municipal water supply.

The project is expected to be commissioned in April 2021 and is partly financed by the World Bank through its National Urban Water Supply Program (NUWSP), which seeks to provide access to improved water sources for the population and strengthen the operational performance of water service providers in selected urban areas.

Source: nxfiltration.com

FILTECH 2021 postponed

With the expectation that Germany will be restricting large events through the first quarter of 2021 due to ongoing complications from the COVID-19 pandemic, FILTECH 2021, which was scheduled to take place Feb. 23-25 in Cologne, has been postponed. New dates have not yet been announced.

Conference organizers are working to identify dates to reschedule the event.

Source: filtech.de

ISO updates standards for treating irrigation wastewater

Nearly half of the world’s population is living in areas that lack sufficient water for at least one month a year and this could increase to up to 5.7 billion in 2050, according to the International Organization for Standardization (ISO).

Treating wastewater to make it available for other uses such as irrigation is a powerful solution to water scarcity, yet it can pose risks to health and the environment if water quality and methods of treatment are not appropriate. ISO has a series of standards to facilitate this safely and effectively, and some have just been updated to be even more useful in today’s environment.

ISO 16075-1, Guidelines for treated wastewater use for irrigation projects – Part 1: The basis of a reuse project for irrigation, and ISO 16075-2, Guidelines for treated wastewater use for irrigation projects – Part 2: Development of the project, are designed to help maximize the benefits and reduce any related risks incurred in agricultural irrigation systems.

These guidelines outline the factors to be taken into account in such projects, namely water quality, soil and climate, the effects these can have on water quality and ways of improving it.

Updates to these standards include additional information such as that related to public and private garden irrigation and further examples of how to improve quality.

The standards are joined by others in the series, also being updated, which include:

- ISO 16075-3, Guidelines for treated wastewater use for irrigation projects – Part 3: Components of a reuse project for irrigation

- ISO 16075-4, Guidelines for treated wastewater use for irrigation projects – Part 4: Monitoring

The revised versions of these are due to be published in 2021.

The ISO 16075 series was developed and updated by committee ISO/TC 282/SC 1, Treated wastewater reuse for irrigation, whose secretariat is held by SII, ISO’s member for Israel.

ISO/TC 282/SC 1 is a subcommittee of ISO/TC 282, Water reuse, which has 22 published standards and a further 19 in development, covering all aspects of water reuse including urban and industrial use, biopharma and the risk and performance of water reuse systems.

The standards are available from your national ISO member or the ISO Store.

Source: iso.org

ATI announces record year of orders for automated filter tester

Air Techniques International (ATI), best known as a designer and manufacturer of photometers and generators used in the clean air and containment industry, announced it has achieved a record year of orders for the 100X Automated Filter Tester.

The 100X combines ATI’s core technologies into a single, compact test unit designed for production, quality control, and R&D applications for test and validation of filter media, cartridges, and masks. In production environments, the 100X provides accurate and repeatable results while minimizing production downtime and maximizing throughput. In QC/R&D labs, the 100X provides the same accurate results while offering portability and quiet operation.

“During the pandemic we saw record demand for the 100X from established media and mask manufacturers, as well as from new organizations entering the market. Our ability to test media and masks to all the major standards, such as GB 2626, was a key decision point for these customers. Short lead times of less than 10 weeks were a big factor too,” said Gautam Patel, Global Product Manager. The range of global standards the 100X meets includes: GB 2626, GB 19083, GB/T 32610, NIOSH 42 CFR Part 84, and EN 13274-7:2019 (Paraffin Oil), which are needed by major filter media companies and manufacturers worldwide.

To test KN95, N95, and FFP style respirator masks, ATI developed an accessory to hold each mask securely in the test fixture and prevent it from being damaged while being tested. The adapter allows the aerosol to enter the adapter and challenge the mask according to industry standards. When the test completes the mask can be easily removed from the adapter and the adapter can be prepared for the next mask test. “The ATI mask test adapter makes it very easy to test your mask. It is simple to prep for testing, yet is sturdy, light weight, and able to accommodate a wide range of mask types and sizes,” said Patel.

The 100X will be featured at Filtration and Separation Asia 2020, Shanghai, China on December 9-11. The event combined with China International Filtration & Separation Exhibition forms the largest filtration event in Asia. Bring your media or mask to booth #C18 and receive a FREE test.

View a short animation and learn more about the 100X: https://www.atitest.com/products/100x

Source: atitest.com

Rensa Filtration acquires Air Filters, Inc.

Rensa Filtration, a family of filtration companies that manufacture best-in-class air filtration products, acquired Texas-based Air Filters, Inc. (AFI). AFI is a full-line filtration manufacturer with over 65 years of experience servicing industries from airports and automotive to medical and museums.

AFI specializes in custom and high-volume manufacturing to meet any air filtration need, from filters to custom parts. Products include pleated air filters to HEPA filters as well as a complete line of Aire-Loc fore-market metal HVAC and HEPA housings. AFI’s pleated air filters–including the patented Expand-A-Pleat—round out Rensa Filtration’s portfolio, making Rensa a turnkey supplier of high-quality, innovative air filtration products.

AFI is Rensa’s fifth acquisition since its inception in 2017. Other members of the Rensa family include Maryland-based Viskon-Aire, Illinois-based Permatron, Michigan- and Ohio-based RoboVent and Michigan-based D-Mark, Inc. Rensa will continue to look to add high-growth companies that are interested in being part of a family of leading-edge filtration suppliers.

Source: rensafiltration.com

Frontenac acquires Newterra Group Ltd.

Frontenac Company, a Chicago-based private equity firm, has acquired Newterra Group Ltd., a global modular water treatment company, from its current shareholders including institutional investors XPV Water Partners and Angeleno Group, LLC. The financial terms of the transaction were not disclosed. Capstone Headwaters and its Water Technology Practice advised Newterra and its board on this transaction.

Newterra is a global leader in designing, engineering, manufacturing, and servicing modular treatment solutions for water, wastewater, stormwater, and groundwater. Founded in 1992 with brands dating back to 1863, Newterra helps clients across a wide range of industries and sectors solve their water and wastewater challenges, offering both standard products and fully customized engineered solutions. Over the past several years in addition to robust organic growth, Newterra has acquired and integrated several companies in key industrial and municipal sectors, broadening its capability to address the needs of global customers with their water and wastewater challenges. President & CEO, Tom Vossman, along with the current executive team, will continue in their roles leading the Company. Water industry veteran and a former Frontenac portfolio company CEO Jim McGivern will join the board.

Source: newterra.com