In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg: ken@filtnews.com

Most recent update: July 29, 2024

Andritz to Design Carbon Capture Plant in Finland

International technology group ANDRITZ has been selected to perform the front-end engineering design (FEED) for a large-scale carbon capture unit for Westenergy’s waste-to-energy plant in Mustasaari, Finland. This project will make a significant contribution to decarbonization and the circular economy.

The order was received from ECCU Ltd, a joint venture of Westenergy Ltd, CPC Finland Oy and funds managed by Prime Capital AG. The aim is to capture all the carbon dioxide from the flue gases of the Mustasaari waste-to-energy plant, which produces district heating and electricity from sorted, non-recyclable municipal waste. The captured carbon dioxide will be liquefied, and a large portion will be made available to produce carbon-neutral synthetic e-fuels.

As the FEED contractor, ANDRITZ will refine the carbon capture plant concept and prepare the design documentation as a basis for the joint venture’s final investment decision. The concept will place a focus on the optimal integration of the carbon capture process into the waste-to-energy plant to maximize the utilization of available heat and the reuse of residues in a closed loop.

Raoul Farer Joins NC State Wilson College of Textiles and Nonwovens Institute

Raoul Farer PhD has been appointed professor at North Carolina State University’s Wilson College of Textiles and executive deputy director at The Nonwovens Institute (NWI).

Dr. Farer will serve as professor in the Wilson College of Textiles’ Department of Textile Engineering, Chemistry and Science (TECS). As executive deputy director with NWI, Dr. Farer will join the Institute’s leadership team, working closely with Behnam Pourdeyhimi PhD, and Tom Daugherty to manage the implementation of NWI’s strategic vision.

Dr. Farer joins TECS and NWI after a 24-year career with Freudenberg Performance Materials in Germany, Spain and the United States, bringing extensive knowledge in textile technologies with a specialization in nonwovens.

Throughout his career, Dr. Farer has championed investments in new equipment and upgrades in technology to improve the uniformity of nonwovens, optimize and modernize technologies to help reduce energy consumption, while also allowing for increased usage of recycled materials. During the Covid-19 pandemic, Dr. Farer and Freudenberg partnered with NWI and NC State to build a full-scale FDA-approved face mask production facility in Durham, North Carolina.

Cleanova Acquires Sidco Filter Co. and Shawndra Products

Cleanova has successfully acquired Sidco Filter Co. and Shawndra Products Inc., two leading clean tech filtration companies based in the U.S. These strategic acquisitions align with Cleanova’s vision to expand its global footprint and strengthen its presence in the filtration industry.

Cleanova, established in October 2023 and owned by the pan-European private equity firm Px3 Partners (Px3), combines fresh thinking with proven technology to provide innovative filtration solutions. The addition of Sidco and Shawndra underscores Cleanova’s commitment to constant innovation and the highest product quality, as they expand their market reach.

Established in 1997 and headquartered in Manchester, New York, Sidco Filter Co. manufactures original equipment manufacturer (OEM) and aftermarket filters for air and gas markets. Shawndra Products Inc., founded in 1982 and headquartered in Lima, New York, provides meticulously designed filter elements. Sidco and Shawndra merged earlier this year to form Sidco Group, prior to the acquisition by Cleanova.

The two companies have built strong reputations for their innovation, quality and customer service. Their mission and vision also closely align with that of Cleanova, with a continual journey towards industry-leading filtration solutions and placing customers at the heart of decision-making.

Kurita America and Solugen to Develop New Carbon-Negative Products for Industrial Water Treatment

Kurita America, part of the Kurita Group, a leading global provider of industrial water treatment solutions, announced a collaboration with Solugen, a bio-based chemical manufacturer, to develop a suite of new carbon-negative water treatment products. These innovative solutions will introduce high-performing, bio-based substitutes to phosphorus and other petroleum derived additives currently on the market.

“We are very excited to expand our partnership with Solugen to create innovative technologies that tackle many of the challenges of traditional water treatment programs,” said Mike Mowbray, senior vice president of the Marketing and Technology Group for Kurita America. “This collaboration will significantly enhance our existing CSV (creating shared value) business that helps customers achieve sustainability goals.”

Kurita’s CSV business, one of the company’s fastest growing segments, focuses on products, technologies, and business models that save water, reduce CO2 emissions, and minimize industrial waste while improving plant productivity for customers. One of the recently developed product lines is the Tower NG series of cooling products, which replaces most of the traditional water treatment chemistries with a combination of the latest polymer technology and Solugen’s proprietary biodegradable corrosion inhibitor. By leveraging innovative bio-based solutions, the Tower NG series eliminates the dependence on traditional organo-phosphonates while providing equivalent or better results for deposit and corrosion control.

Pentair and MSP Airport to Collaborate to Reduce Single-Use Plastic Waste

Pentair plc, and Minneapolis-St. Paul International Airport (MSP) announced a new collaboration to sustainably deliver great-tasting, high-quality drinking water while reducing the need for single-use plastic water bottles for the millions of travelers that visit and fly through the MSP international hub each year. MSP, owned and operated by the Metropolitan Airports Commission (MAC), is the 19th busiest airport in North America by passenger traffic.

Pentair is the first partner in MSP’s new strategic partnership program which aims to collaborate with businesses and community organizations to enhance the passenger experience and drive innovation. As the Official Water Sponsor of MSP, Pentair is working to help the airport promote sustainability through the installation of 10 HOPE Hydration HydroStations. The cutting-edge HydroStations are the first water refill stations of their kind at any airport worldwide, dispensing free, chilled, and filtered water while providing an interactive experience to users. Through the HydroStations, Pentair and MSP will be educating travelers about water-related issues and the positive environmental impact they can make by bringing and filling a reusable water bottle while traveling.

Each of the HydroStations feature filtration technology by Everpure from Pentair Water Solutions, providing MSP employees and travelers with a free, great-tasting and more sustainable alternative to single-use plastic water bottles.

It is estimated that the current network of 80 water bottle refill stations at MSP reduce the need for approximately 600 pounds* of single-use plastic bottles every day. Using integrated IoT technology, the HydroStations at MSP track real-time impact data associated with the elimination of single-use plastics including plastic and carbon emissions savings, which will be displayed on each HydroStation.

MANN+HUMMEL Appoints New President & GM for the Automotive Aftermarket

MANN+HUMMEL, a leading global supplier of filtration solutions, has appointed Cedric Dackam as the new President & General Manager for its Automotive Aftermarket division comprising Original Equipment Service for Passenger Cars and as well as the Independent Aftermarket for Passenger Cars and Heavy Duty Vehicles and the Industry sector. The division offers a comprehensive product portfolio of high-performance filters and system components for motorcycles, cars and trucks, regardless of the type of drive system.

Dackam has held various management positions at the Ludwigsburg-based filtration company since 2002. Most recently, as President & General Manager of Water & Membrane Solutions, he was responsible for managing and steering the activities of this business unit and driving its growth. He holds a Master of Science in Chemical and Process Engineering from the University of Karlsruhe (KIT) and an MBA from Western Michigan University, USA.

In his role, Cedric Dackam succeeds Stefan Tolle, who is entering retirement: “I wish Cedric every success in his new role. He has a wonderful team and years of experience from a range of areas within the organization to build on, which is why I am confident that he is a great choice to successfully manage the upcoming tasks.”

“Stefan has done an amazing job for the past three years, preparing our transformation coinciding with the changes in the automotive industry, always keeping our customers in the spotlight. Now that he is leaving for his well-deserved retirement, I am proud to have Cedric on our team to tackle new challenges”, said Kurk Wilks, CEO of MANN+HUMMEL.

NX Filtration Announces CEO: Floris Jan Cuypers

NX Filtration, the global provider of hollow fiber nanofiltration technology, announced the appointment of Floris Jan Cuypers as new Chief Executive Officer (CEO), effective September 1, 2024, to lead NX Filtration through its next stages of growth. Cuypers has a strong track-record of executive leadership positions focusing on commercial impact and operational excellence. Floris Jan Cuypers is succeeding Jeroen Pynenburg, who will step down as CEO at the end of July 2024. NX Filtration also reports half-year 2024 revenues of €5.9 million, an increase of 57% versus the first half-year of 2023, and reconfirms its full-year revenue outlook.

Floris Jan Cuypers (1978) brings a wealth of experience in leading and growing international organizations. Between 2018 and 2023 he served as Chief Operating Officer (COO) and Chief Commercial Officer (CCO) at ERIKS, a global industrial service provider, offering technical products and services to all sections of industry. At ERIKS, he also assumed an ad interim role as CEO of its Dutch operations between 2021 and 2022. Since 2023, he has been COO at SHV Energy, providing decentralized, low-carbon and clean energy solutions to business and residential customers around the world. Floris Jan Cuypers is a Dutch national and holds a Master of Science in Applied Physics from Delft University of Technology in the Netherlands.

Blueair Reveals New Air Purifier with Professional Grade Air Purification

Air wellness pioneer Blueair unveiled its most advanced and powerful air purifier to date – the Classic Pro. Building on the award-winning Classic family of air purifiers, the new model is re-engineered with first-of-its-kind multi-layer filtration technology to deliver 40% more performance than before1 and cleanse the air in rooms up to 1,413 square feet2 in as little as 30 minutes.

Blueair artfully engineered Classic Pro to provide long-lasting, advanced protection against indoor air pollutants that can adversely affect consumers’ quality of life. Equipped with Blueair’s proprietary HEPASilent™ dual filtration technology, the Classic Pro can quickly capture 99.97%3 of particles as small as 0.01 microns in size. The unique filtration process delivers more clean air faster while using less noise and energy than HEPA filtration alone4.

For an added layer of protection against particulates, the Classic Pro is the first air purifier to bring the patent-pending PhotonPure™ lighting technology to consumers’ homes. Previously only used in medical settings, this professional pioneering lighting technology targets the main filter’s surface with a safe violet light to reduce up to 91% of harmful viruses5 and bacteria6 trapped on the filter to prevent recirculation into the air. This visible protection is different from ultraviolet-C (UVC) lighting typically seen in air purifiers, as PhotonPure™ operates in a visible wavelength of 405nm compared with traditional UVC. The PhotonPure™ antibacterial lighting technology can ensure long-term, effective usage of the Classic Pro without degrading the air purifier’s filter materials and performance over time. The Classic Pro has a visible blue light that can be seen behind the filter, turning on every 10 minutes.

ZwitterCo secures $58.4m in Series B funding led by Evok Innovations

ZwitterCo, which is transforming water treatment through advanced membrane technologies, announced the successful close of its Series B funding round led by Evok Innovations. Evok was joined by DCVC, BHP, Munich Re Ventures, SiteGround, HG Ventures, and Blue Horizon Advisors. The oversubscribed $58.4 million round will accelerate ZwitterCo’s mission to unlock the potential of unconventional water sources, such as industrial wastewaters and more challenging surface waters or process streams, to meet the massive water demands of industries that underpin a low-carbon future.

“Climate change is simultaneously driving water scarcity and increasing demand for water in industries critical to the low-carbon transition,” said ZwitterCo Co-Founder and CEO Alex Rappaport. “This funding will allow us to rapidly scale our breakthrough membrane technology, empowering industries to reliably and affordably access unconventional water resources while ensuring the water used or recycled in these industries meets the highest purity standards.”

While membranes are ubiquitous in water treatment, there had been no breakthrough innovations in the field for half a century until ZwitterCo introduced membranes with novel zwitterionic chemistries. ZwitterCo’s technology creates unprecedented immunity to organic fouling, enabling ZwitterCo’s membranes to continue working efficiently and sustainably long after traditional membranes would have clogged.

The need for such advanced membrane technology is rising as the changing climate worsens regional water shortages. According to the United Nations, 2.2 billion people globally lack access to safely managed drinking water services, and by 2025, half of the world’s population could be living in water-stressed areas. Additionally, the U.S. Office of the Director of National Intelligence sees a 20-50% rise in global water demand by 2050. As conventional freshwater resources become increasingly strained, the ability to tap into unconventional water sources will be critical for meeting the growing demand for clean water.

Kovalus to Invest $20M in State-of-the-Art Spiral Assembly Factory

Kovalus Separation Solutions, formerly known as Koch Separation Solutions, is making a significant investment of over $20 million dollars in a new 140,000 sq-ft (14k m2) state-of-the-art facility for spiral membrane element assembly in Mexico. This new facility will enable a 50% expansion in spiral membrane production capacity, effectively addressing the growing market demands in the Food, Beverage, Life Science, and Industrial sectors.

“We are extremely excited about this investment in our growth,” said Manny Singh, CEO of Kovalus Separation Solutions. “Membrane technology allows our customers in food, beverage, dairy and industrial applications to significantly improve operational sustainability and profitability, through increased product yield, purity, and water reuse. The increasing demand for our products has prompted an exhaustive evaluation of potential locations for expansion. After careful consideration, we have chosen Mexico due to its proximity to key markets, availability of skilled labor, and rapidly improving infrastructure.

All core membrane technology for spiral products will continue to be manufactured at our Massachusetts headquarters using the same materials, machinery, and quality procedures. This alignment with our Quality Management and Membrane Development teams will ensure consistent product performance and help to support future innovations.

This investment underscores our commitment to enhancing our production capabilities and reinforcing our leadership position in the membrane technology market. It follows our earlier investment this year to expand production capacity at our RELCO facility in Willmar, Minnesota, USA.

The new facility in Mexico is expected to begin operational qualification in late 2024, marking a significant milestone in our expansion strategy.

Ahlstrom Introduces Fluoro-Free Filtration Materials

Ahlstrom is launching a new range of filtration materials that offers fluoro-free technology. Ahlstrom is extending its innovative fluoro-free technologies into a wide range of industrial air filtration applications to support filter manufacturers in creating products with long-lasting filtration performance without the use of fluorochemicals.

Ahlstrom’s new fluoro-free filtration materials are ideal for gas turbine air intake, air pollution control, heating, ventilation, and air conditioning (HVAC) applications. The new range of materials offers water-repellent properties, which increase the durability and stability of the final filter in wet conditions. In global filtration markets, hydrophobic properties are essential to maintaining the highest filtration performance in challenging environments.

In air pollution control applications, for example, hydrophobic materials save energy by limiting the pressure drop increase in humid conditions. Specifically, in gas turbine applications, water repellency prevents liquid water ingress and dissolved salt penetration through a filter, protecting the turbine from corrosion.

Grundfos Appoints Hamed Heyhat to CEO Water Utility Division

Grundfos has appointed Hamed Heyhat as Executive Vice President and Divisional CEO, Water Utility.

Heyhat, who will be part of Grundfos’s Group Management, brings more than 20 years of experience from the utilities industry gained at international companies such as Alstom, General Electric Company and most recently Honeywell. He joins Grundfos from a role as president of Honeywell’s Smart Energy business.

“Hamed Heyhat brings deep knowledge from the utilities industry, many years in senior leadership and a proven track record in roles with profit and loss responsibility, as well as mergers and acquisitions,” said Poul Due Jensen, CEO of Grundfos. “He has an ambitious, present and authentic leadership style, and I am confident that he is a great fit for Grundfos, and our Water Utility division.”

Heyhat has a Bachelor of Science in Electrical Engineering from Iran University of Science and Technology, and an MBA from Manchester Business School.

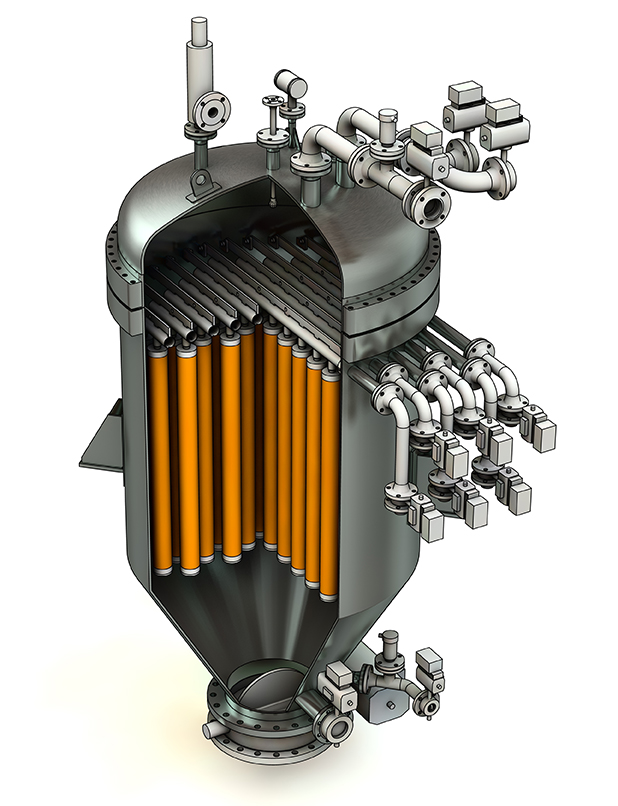

NX Filtration Receives Orders From Thermax for Projects in India

NX Filtration, a global leader in advanced hollow fiber membrane technology, announced that it has added Thermax Ltd., an Indian multinational engineering company involved in clean air, clean energy and clean water, to its customer base. Thermax has placed a sizable initial order for both hollow fiber nanofiltration and ultrafiltration modules from NX Filtration.

With over 40 years of history, Thermax is among the prime Indian companies focusing on water and wastewater treatment, with more than 20,000 water and wastewater treatment installations across various municipal, industrial and commercial applications.

After extensive successful piloting with NX Filtration’s hollow fiber nanofiltration technology, Thermax will now be scaling up to full-scale water projects. Thermax initial order involves hollow fiber nanofiltration modules with an aggregate total capacity of approximately 5 million liters per day, and ultrafiltration modules with a total capacity of approximately 25 million liters per day and will be used for various of its existing and new water treatment installations across India.