ASTM Committee E29 announced the new Standard Test Method for Bubble Point Pressure of Woven Wire Filter Cloth.

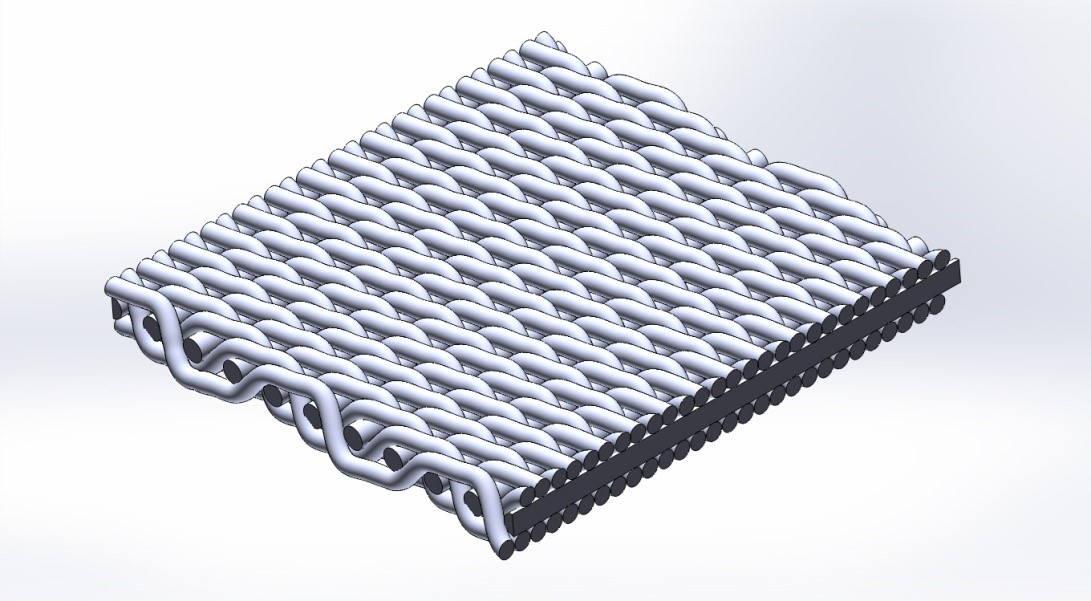

Woven wire filter cloth (aka. Dutch weave) used for general industrial filtration including the separation of solids from fluids (liquids or gases) is covered under ASTM Specification E2814. Users of filter cloth often have a desire to classify specifications based on a pore size for some filtration rating criteria.

Accordingly, the bubble point test determines the pressure at the largest pore in a specimen and converts that to a pore size by applying a calculation factor for each filter cloth specification.

Standard E3278 addresses the shortcomings in the historic ARP901 reference, and provides a technically robust document with the pore size calculation factor based on the most current computer geometric modeling techniques.

The new Standard will benefit both users and producers of woven wire filter cloth by identifying, controlling, and mitigating uncertainty from bubble point test specific variables, resulting in more accurate and consistent test results.

Standard E3278 is under the jurisdiction of ASTM International Committee E29 on Particle and Spray Characterization, and is the direct responsibility of Subcommittee E29.01 on Sieves, Sieving Methods, and Screening Media.