There are three primary property considerations of fibers for filtration performance — the choice of fibers, the process of producing the media and the final application.

When it comes to performance, the fundamental fiber properties are those that are designed to optimize volume, air permeability, and the pore size of the material. Volume and air permeability work in combination and affect the dirt holding capacity. Pore size is associated with the size of particle that is capable of penetrating the media, essentially this characteristic dictates filtration efficiency.

Each of these properties can and do affect the others, and there is a balance needed to optimize the filter for the application.

Fiber size matters

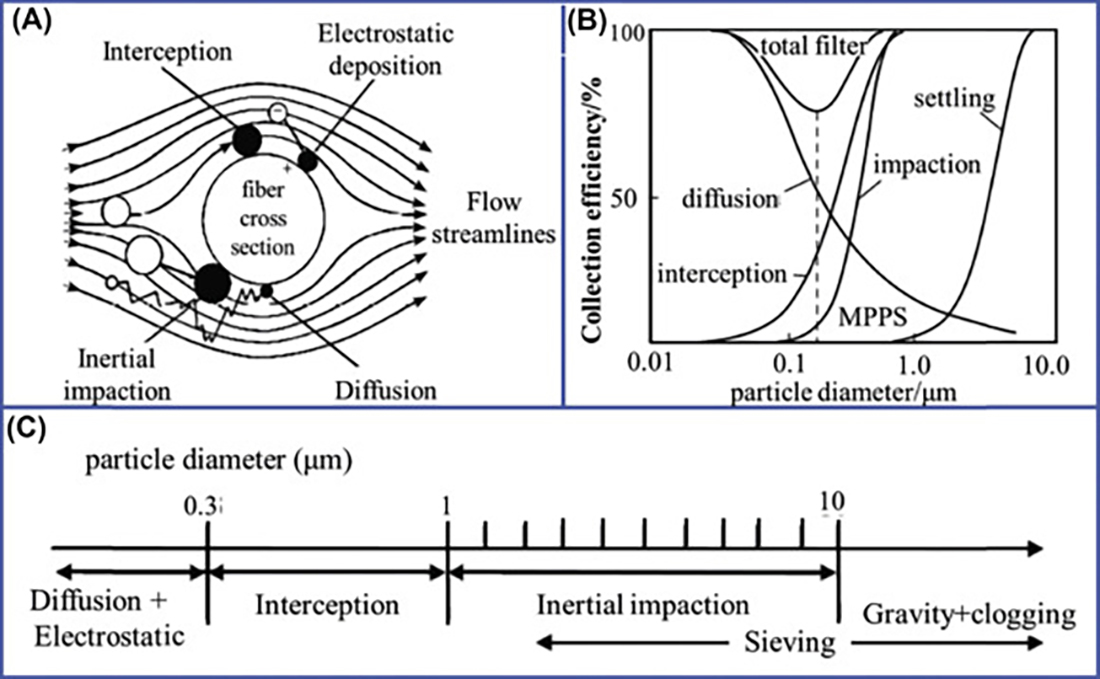

The filtration process is only as good as its filter’s ability to capture particles. There are a number of different filtration mechanisms for collecting particulates either on the surface of the media or via penetration within the media. Primary mechanisms, of which there are four, include:

- Inertial impaction;

- Diffusion (Brownian motion);

- Interception and electrostatic effects; and

- Indirect interception (the dominant filtration mechanism for modern air filter products).

It has been my experience that as the fiber diameter increases, the probability of dust deposition would increase significantly on the surface of the fiber and between the fibers. Filter pore size and fiber diameter also have a significant affect on the dust deposition rate in the initial stage of filtration within the depth of the filtration media, and the effect is gradually weakened as the filtration process progresses.

There is a lot of physics at work in filtration, but to keep it simple, this is how these mechanisms work in practice:

- If the fibers are much smaller than the particles, filtration is a result of Impaction and Interception.

- If the fibers and particles are similar in size, filtration is a result of Impaction, Interception and Brownian Diffusion.

- If the fiber is much larger than the particles, filtration is a result of Impactions and Brownian Diffusion.

Torturous path

It takes two to tango, and it’s a torturous path. Fibers and particles have a mutual relationship, but they behave differently based on their relative sizes. As an example, if a particle touches a fiber, it gets captured most of the time. In this interplay, the size and shape of the fibers are significant. A small fiber diameter is the prevailing method for increasing filtration efficiency as it creates a dense porous structure. A larger fiber diameter creates a more open structure, but one with less efficiency.

Fibers can be round or angular in shape. An angular fiber typically provides a higher surface area than a round fiber and raises efficiency. The exception to this rule is a fiber that is flat, as a flat fiber does not create a torturous porous structure and thus limits or even prevents flow.

Other factors

Other factors to be mindful of are those related to the strength of the fibers as they also play a part in efficiency. These properties are modulus and tenacity. Modulus is a term that describes how flexible or ridged a fiber is. Tenacity is the breaking strength. A high modulus fiber in a filter media tends to be one with a lower filtration efficiency because the fibers are ridged and don’t densify. Tenacity would seem to be a driver of strength in a nonwoven filter media, however equally, if not more importantly, is the bonding of the fibers. Lastly, fiber orientation, or the amount of uniformity in the fiber direction influences the filtration performance by optimizing pore size, strength and overall contact area.

Nanofiber

Nanofibers are exciting technology! Most times nanofibers are added to other fibers to enhance many properties. Since size matters, adding even an almost imperceptible amount of nanofiber dramatically improves filtration efficiency at a relatively low pressure drop. Adding nanofibers also extends the life of the filter by making it easier to clean because the fibers keep the particulate at the surface rather than depth loading.

Chris will be addressing these points and more at his upcoming “Filter Media Training,” Feb. 25-26, 2020, in conjunction with FiltXPO at Navy Pier in Chicago. For more details and to register, visit www.inda.org/education/filter-media-training.php.

* International Filtration News is owned by INDA, Association of the Nonwoven Fabrics Industry.

![Figure 1: Heat Exchanger Proventics GMBH.[22]](https://www.filtnews.com/wp-content/uploads/IFN_2_2024_crimpedmicrofiberyarns_Fig.-1-Heat-exchanger-225x125.jpg)