For over 68 years, Chase Machine and Engineering has been designing and building a variety of standard and custom converting machinery for Woven-Nonwoven Fabrics, Films and Foils. From integrating independent modules to supplying Full-Scale Production Lines, we offer a comprehensive range of machinery that play an essential role in the success of well-known brands and products worldwide.

As one of the premier design and manufacturing companies for custom web handling machinery, Chase serves a wide range of customers in the Textile, Medical, Nonwoven, Converting, Geotextile, Extrusion, Filtration, and Packaging Industries. We partner with leading manufacturers to produce application-specific equipment ranging from Festooners, Accumulators, Inspection Machines, Unwinds/Rewinds and Traverse Winders, to Ultrasonic Slitters, Laminators, and Cut-To-Length Machines.

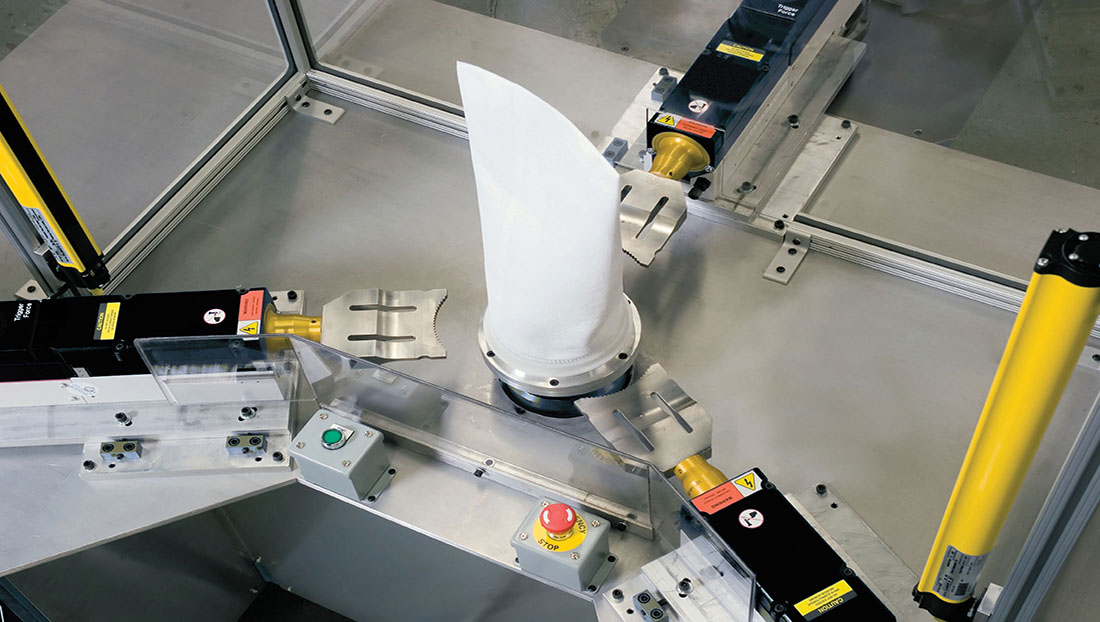

Chase specializes in the integration of technologies such as Ultrasonics, Impulse Welding, RF Welding, Band Sealing, Hot Air Welding, Glue Dispensing, Hot Knives and Conventional Blade Slitters as well as Vision and Marking Systems.

Chase is a vertically integrated company, utilizing State-of-the-Art 3D Solid Modeling Software for our machine designs. Within our 28,000 sq. foot facility, located in West Warwick RI, we program our PLC’s and HMI’s, build our Electrical Control Panels and Machine, Weld/Fabricate, Paint and Assembly our Equipment while maintaining tight control of quality and delivery.

Chase specializes in the integration of technologies such as Ultrasonics, Impulse Welding, RF Welding, Band Sealing, Hot Air Welding and Glue Dispensing, and more.

We place a high priority on customer and product confidentiality, and constantly seek to improve our quality and process controls as we help our customers improve their products and processes. Working together with our customers, Chase will deliver equipment that is newer, faster, more efficient, and more reliable for a timely return on your investment.

For those interested in product development, the Chase Materials Application Lab exists to help your team take their ideas to the next level. Whether creating new products or improving existing ones, Chase can determine the optimum method for manufacturing. Lab capabilities include web handling systems with ultrasonic technology for laminating, embossing, welding, slitting as well as impulse welding machines.

Visit us at www.chasemachine.com and learn why Chase Machine and Engineering has adopted the tagline “EXPECT TO BE IMPRESSED.”

This content is sponsored by:

Visit us at FiltXPO: Booth #804