Standardized facemasks typically fall into one of two categories — surgical or respirator. Both variants are designed to offer various levels of protection against the transmission of bacteria and other particulates. World facemask guidelines are about science, but go beyond that. The science is defined by test methods that each region/country espouses. As a rule of thumb, facemasks for medical applications have the highest filtration ratings, as they filter bacteria-sized particles (BFE ≥ 95% to BFE ≥ 98%) and some virus-sized particles (PFE ≥ 30% to PFE ≥ 98%).

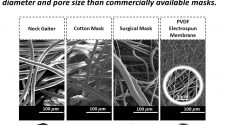

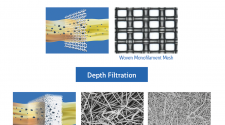

The purpose of the two categories of facemasks is fairly straightforward. Surgical masks are loose fitting and generally are designed to protect others from you, in the event you sneeze or cough. Whereas, respirators – often referenced by their standard codes of N95, KN95 or FFP1, etc. – are form-fitting and protect the wearer. Globally these masks are primarily utilizing a charged meltblown material as the primary filter media, although there are some technologies that utilize mechanical means by way of nanofibers or other membrane substrates.

Supply chain issues

The supply of N95 masks and equivalents in Europe and Asia was so stressed during the early phases of the pandemic because the majority of these style of masks were manufactured in China and Taiwan. Early on, both countries restricted exports of the charged meltblown nonwovens, as well as the finished facemask. The world did not have the machine assets outside these regions to facilitate the ultra-high demand the pandemic has created. These regional requirements have been addressed, but machines take many months to build, install and get up and running, so the backlog demand for facemask is now reaching into 2021.

Many studies indicate that cloth facemasks are better than nothing, but the science indicates that as a filtration device the cloth mask is rarely more than 20% efficient against the coronavirus we are dealing with today. This is a sobering statistic and one that provides a false sense of security.

Facemask performance

The U.S. Centers for Disease Control (CDC) recommends cloth face coverings as a simple barrier to help prevent respiratory droplets from traveling into the air and onto other people when the person wearing the cloth face covering coughs, sneezes, talks, or raises their voice. Many studies indicate that cloth facemasks are better than nothing, but the science indicates that as a filtration device the cloth mask is rarely more than 20% efficient against the coronavirus we are dealing with today. This is a sobering statistic and one that provides a false sense of security. I agree that a cloth mask is better than nothing, but not much better, and potentially dangerous, especially in areas that have high contact intensity.

Facemask standards

Globally there are a number of agencies that establish standards which rely on specific methods to test and validate facemasks. In the United States, the National Institute of Occupational Health and Safety (NIOSH) is responsible for standard development, testing and validation for the workforce. The Food and Drug Administration (FDA) oversees the facemasks that are utilized in medical applications. Other countries establish similar standards and regulatory bodies and their facemask standards are very similar but not harmonized.

Early on in the pandemic there were issues related to counterfeit facemasks, which claimed to meet N95 and KN95 standards. Much of these products originated in China and were manufactured by groups that sought to opportunistically market products. Unfortunately, in their haste to get to market, they manufactured and sold products that did not meet global standards. These companies were quickly identified and shut down, as validation processes identified the products that didn’t meet the standards and eliminated them from the market.

A civilian grade facemask

Sun Tzu said, “In the midst of chaos, there is also opportunity.” From the chaos of counterfeit and short supply, the world was driven to evaluate what facemask resources they have and how to validate these materials for new “civilian grade” applications. Individual countries and teams of countries have been working together to validate and define materials that are better than textiles but that do not meet surgical or respiratory grades. There are currently no standards in place to meet this need and are validated as both source and respiratory controls.

The materials and equipment necessary to make equivalent surgical- and respiratory-grade facemasks is, as noted earlier, in short supply. All areas of the supply chain have been affected from resin, electrostatic charge additives and all the associated equipment to manufacture and test has been stretched to the limits. The world has stepped up to the challenge with investment, but the one thing that cannot be bought is time.

To bridge the gap between the material capacity investments currently being made in the U.S., we need a superior civilian grade facemask which offers an appropriate level of protection for the user and that does not stress the supply chain of N95 or surgical mask resources. This need is being addressed in the U.S. by a team of experts within ASTM, NIOSH and industry to quickly bring decades of experience and ingenuity together to solve the issue.

Also, INDA, The Association of the Nonwoven Fabrics Industry, has reached out to its nonwoven manufacturing members to seek alternatives to the short-supplied meltblown nonwoven to meet the growing need for medical/surgical respirators and masks. What was found is an abundance of nonwoven material produced from other nonwoven methods that could approach the filtration performance of N95, but could not quite meet that level of efficiency. This group is working to develop a media specification as a precursor to the ASTM specification.

The future

Looking ahead the big challenges for facemask technologies and standards is to execute a standard for a civilian grade facemask, which will meet the need and set the stage for respiratory and environmental relief for this and future pandemics. We are in this together and have the opportunity to use the lessons learned to better prepare and adapt to a changing world. Communication of this new specification will be critical. The N95 specification moniker is burned into the psyche of the American public as the gold standard. In a nation that reveres having and being the best, positioning the civilian grade mask in a way that will foster acceptance and adoption by the general population will be crucial.

* International Filtration News is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).