A comparative performance assessment of various facemask technologies

There are two realities when looking for a protective mask: one, people want a choice; and two, they need to be able to trust those who make the masks and the performance statements they make. Many masks that have been sold since COVID-19 first arose offer some generic level of protection, but distinct features in fashion, gadgetry, sustainability, etc. Filtration performance and fit aren’t always top considerations. Then again, some claim “KN95” performance but they don’t fit well or even lack the actual certification to prove protection. All these features and claims are confusing, and they led us to try to answer the question, “What are the facts behind all this fluff and marketing?”

A surprising initial finding in a comparative study on facemasks we conducted, was that for people who have a full beard, protection is generally cut in half. Because virus-loaded aerosols go with the airflow, when the air goes towards the mask, it can go around the mask and through the beard and be inhaled. Many people still don’t know (or acknowledge) this. (14Steven E. Prince, 2021)

Misinformation abounds

During this study it quickly became evident just how much facemask misinformation, or misleading information is in the marketplace. For example, there is a company called the “N95 Mask Company.” This company doesn’t make N95 masks though; they make KN95 medical masks. And while the U.S. Food and Drug Administration has been recommending KN95 masks during the pandemic because there was a shortage of N95 masks at various periods during the past two years, KN95 masks account for 60% of the counterfeit masks. That means, out of 10 product offerings claiming to perform like KN95, only 4 products really do, if worn correctly.

It is important to understand the standards and regulations and also the test methods that are the basis for all the performance data and claims that facemask companies make. For the purposes of this study, data and test reports from facemask companies were examined to better understand the filtration performance variables of facemask technology, as well as the amount of plastic waste resulting from facemask use during the pandemic. Facemasks lying on the floors in shopping malls, in parking lots and on the street were a serious issue, so sustainability will be an important part of facemask design in the future.

Clarifying standards

There are many standards related to facemasks. In the U.S. the N95 standard from National Institute for Occupational Helath & Safety is one of the more prominent and well-known thanks, ironically, due to its infamous shortage in 2020. Also, there’s an American Society for Testing and Standards (ATSM) medical/surgical mask standard (not protecting from inhaling virus-filled aerosols), and the new standard for general public facemasks and barrier coverings (ASTM F3502-21). There are two levels to this new standard in terms of how well it filters out particles and aerosols and how easy it is to breathe through. The lower levels for filtration and ease of breathing are quite simple to achieve – however, they are still more relevant for COVID protection than surgical/medical masks are because they are made to fit close to the skin. Surgical masks are designed only to prevent direct splashes from sneezing or spitting, including, of course, the open wounds during surgery. Evaluated as the critical aspects of this study are mask fit, filtration efficiency, and breathability or comfort.

Equivalently in Europe, there are facemask/respirator standards referred to as FFP1, FFP2 and FFP3 with FFP2 being most known (and similar to N95). In China there’s the KN95, which pretty much follows the U.S. N95 standard, and, lastly, the Korean standard, KF94, which is equivalent to the FFP2 standard in Europe.

During this study it quickly became evident just how much facemask misinformation, or misleading information is in the marketplace.

With all the standards around facemask technology, there are test methods to determine filtration efficiency and breathability/pressure drop, as well as chemical resistance, splash resistance, etc. But a test method referenced by itself is not very meaningful. Nonetheless companies often advertise with a particular test method, but they do not report the actual results neither on the product packaging nor their websites. Some even do not provide the data upon request. And some are just fake and worthless. A standard, like N95, prescribes the level of performance for a mask, and test methods prescribe how those properties need to be measured.

Performance unmasked

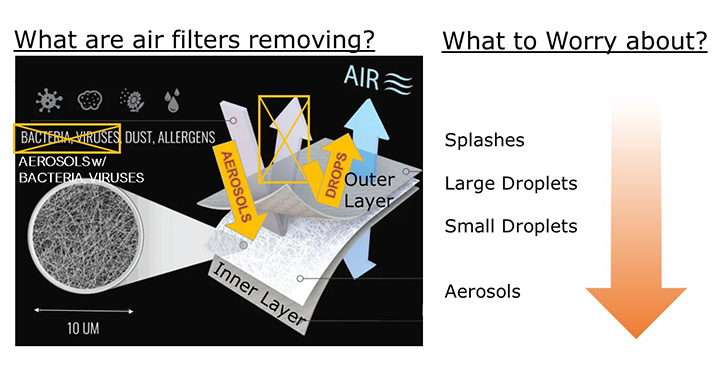

We were also looking at different facemask technologies. The aim was to identify what are these filters actually removing from the air. Common multilayer masks typically remove small particles like allergens and dusts, but not viruses or individual bacteria. Fortunately, the viruses and bacteria that are in the air are inside aerosol droplets, typically small water droplets that are loaded with bacteria and viruses. And so, what really needs to be protected against are splashes of somewhat larger droplets, and the very fine droplets that get into the aerosols that linger in the air around people.

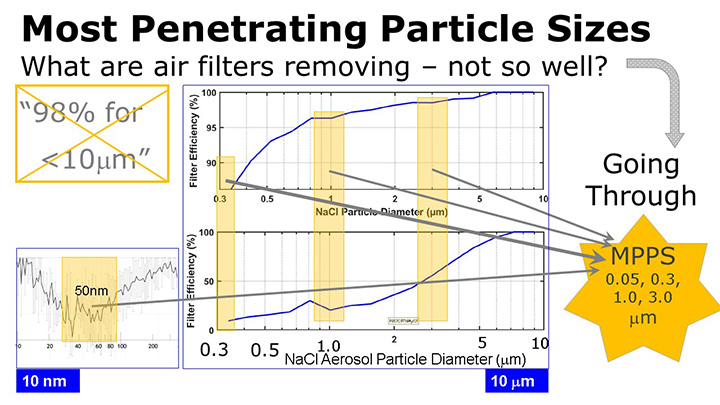

Of the facemask technologies currently on the market, it is common to see performance statements indicating, for example, that their technology removed 98% of particles smaller than 10 micrometers. This is a misleading statement.

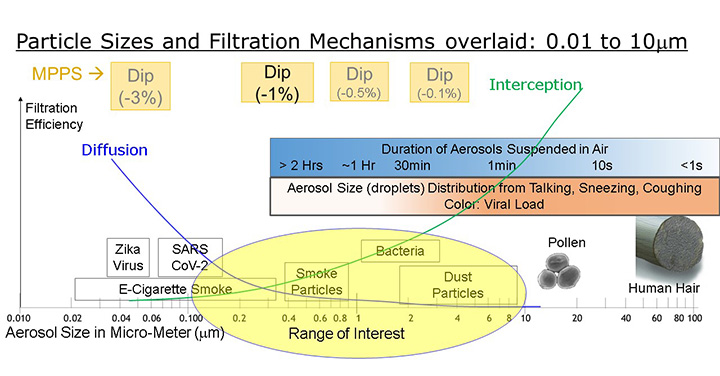

In the chart provided (Figure 1), filtration is shown through masks for particles from 10 nanometers on the far left to 10 micrometers on the far right. As one can see, the filtration efficiency is not constant across all these particle sizes. There are weaknesses in the mask and filtration technologies. This means that there are what’s called the most penetrating particle sizes (or MPPS). For each of these orange bands, there is a hole, or a door cracked open because the filter mechanisms cannot prevent those particle sizes from passing through the filter. There are literally holes in the filtration spectrum. (10Norbert Serfozo, 2017) (1Anand, 2020)

In looking at these holes, the MPPS zones are around 50 nanometers, 0.3 micrometers, 1 micrometer, and 3 micrometers. What does this mean for protection from viruses like SARS-CoV-2?

Filters work in different ways, depending on the size of the particle (Figure 2). For very large particles, around 10 micrometers or bigger – like grains of sand – they just get stuck like sediment gets stuck between rocks. But then for the other extreme, very small particles in the nanometer range, diffusion becomes dominant and even electrostatic attraction. With particles that are between one and 10 microns, filtration is pretty much by inertial impact, too heavy to get around the obstacle. If the particles are around one micron to half a micron, we’re looking at what’s called interception, scraping by and getting stuck. When there’s fast airflow, larger particles can be attracted to fibers (too heavy to follow the air current around), but then others might not be intercepted because they’re too lightweight. Their mass isn’t high enough. At smaller sizes, diffusion becomes dominant, critical in the submicron-to-nanometer size of particles, or aerosols.

The chart shown here (Figure 3) shows the filtration of aerosol particles from 10 nanometers to 10 micrometers – from volatile chemicals to viruses and bacteria and all the way up to scales of the human hair in the 50-100 micrometer range that are in the air.

Aerosol science tells us that large particles like hair or raindrops, fall out of the air very quickly, in less than a second. When looking at very small particles, they hang around in the air for several hours. What about those tiny aerosol droplets? There’s good news for COVID-19 infection prevention here, as those droplets may not be as much of a concern for infection. Research studies have shown that only aerosol droplets larger than about 4 micrometers can hold a dangerous number of SARS-CoV-2 viruses in them. (4Lee, 2020) [12Stadnytskyi, V., et al. 2020] (3Duguid, 1946) Those droplets are indeed dangerous, but for average-to-good filters, these particle sizes are not a problem. Remember that generally, filtration gets better with larger particle sizes, except for those doors where we have the MPPS particles. The big door is leaking at 50 nanometers, which, according to the current research, isn’t large enough to contain a dangerous amount of virus.

How about larger particles, like around 0.3 microns and bigger? Fortunately, the dip for particles bigger than one micron is less than 1%, so it hardly makes a difference in the actual filtration efficiency. The particle sizes that we have to worry about are 0.3 microns to 1 micron. And these are covered by interception mostly. NIOSH test methods and the European equivalent test methods for FFP are testing around that range. So, if a filtration efficiency is good around 0.3 micron to 1 micron, then the larger virus-loaded aerosol droplets are not a concern for facemasks that have legitimately passed the test method. That’s good news and facilitates our facemask evaluations.

Study methodology

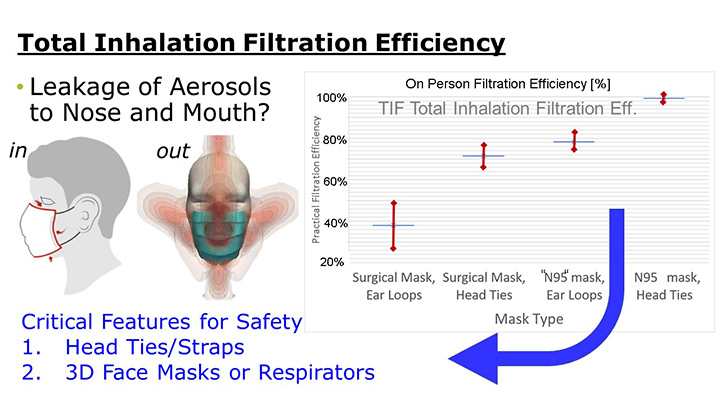

With this information established, our goal then was to determine whether, if the filter is performing well, there could be other cracks in the filtration armor. Aerosols go not only through filters, but they can go around filters and masks.

Figure 4 is based on research that has studied what is called the total inhalation filtration efficiency, or TIF for short. (11Shaji Skaria, 2014) (9Neil J. Rowan, 2021) (6,7,8Makermask.org, 2019) It measures all kinds of ways that particles can get into the nose or mouth. The filtration efficiency for surgical masks with ear loops, for example, is around 40% with a lot of leakage around the mask. What it also studies are not only what is breathed in, but also what is breathed out. The amount of leakage that occurs, or the lack of filtration efficiency, is relevant not only for the wearer, but also for the people exposed to breath from the wearer.

A surgical mask with head ties, like those typically worn by surgeons in the operating room, provides double the filtration efficiency of a standard surgical mask. A similar story we see for N95-type masks like those, namely KN95, that have ear loops. Normally their efficiency is about 80%, while N95 masks, which have head ties or head straps, the filtration efficiency increases to almost 100%, with only a 2% leakage. So, the learning is that facemasks with head ties or straps provide more total filtration efficiency than those with ear loops. Likewise, it is apparent that there is a big difference between surgical masks and 3D masks, like N95, KN95, etc. (13Stahl, 2021) (2Clapp, et al., 2020) (5M.Blachere, et al., 2021)

Our study used six criteria from filtration performance to sustainability, as well as some unique, innovative features. The study considered:

- Two-way filtration (inhale and exhale)

- Seamless design construction

- Ease of sanitization

- Comfort level for extended periods of wearing

- Ability to maintain good voice quality

- Environmentally friendly materials

The study examined different types of masks, including cloth masks, medical-grade respirators, those with transparent fronts, ear loop-free masks, those with and without valves, and some that came with UV sanitization chambers. Those made from very unique materials, such as bamboo or silk were also considered, as well as branded wear with filtration technology embedded within the garments. Award winners from various conferences around the world, those in the news and anything that was really mainstream, or industry-acknowledged, were considered.

Data transparency

Gathering data on these criteria were not easy. Most companies had their filtration features and performance claims visible on their websites, and they were promoted on additional pages, not just the home page. But in many cases, they didn’t make it clear whether their claims were backed by lab tests and if they had certifications that backed these tests. And if they had performed tests and received the certifications for them, often they were not accessible on their websites or anywhere online.

During our outreach to gain insights, several companies stated that their results were not available to the general public. This was very disappointing which means the average consumer is not able to get the information they need to make an informed decision on certain facemask technologies. If test results were not available or provided, we considered the NIOSH or ASTM standards to establish the performance requirements to be considered certifiable. Unfortunately, it was necessary to make educated guesses and inferences. The current environment is certainly murky, and that should be a red flag for the average consumer and is an area for improvement in the facemask manufacturing space.

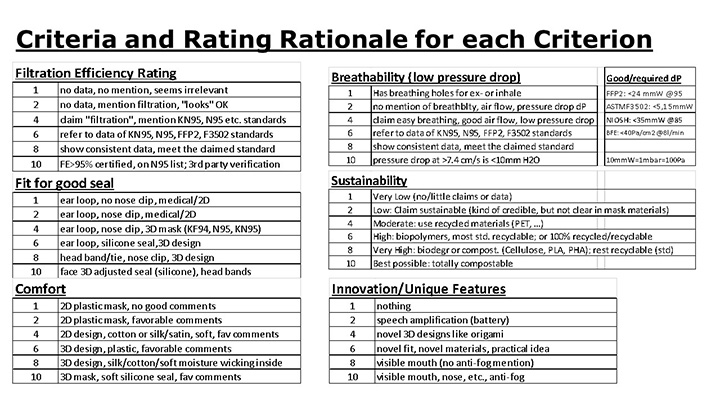

Once the data was gathered, it was clear the masks were quite diverse in quality. To help normalize and evaluate the material for the study, a rating system was used to show how well the criteria were met. If there was no data or mention of filtration efficiency, for example, the mask received a 1 rating for filtration efficiency. If the manufacturer did mention filtration efficiency and it looked like the mask might actually filter something out, then the mask received 2 points. If the manufacturer actually claimed filtration efficiency and professed to have some quality with respect to that, and they mentioned KN95, N95, or other standards, then the mask received 4 points. If the manufacturer actually referred to data like test reports that labs had done for them, the manufacturer received 6 points in the area of filtration efficiency. If the manufacturer showed the data and the data were consistent with a claimed standard, we gave it 8 points. And if the manufacturer exceeded the standard and the proven certificate, and there was a third-party verification, then it received 10 points.

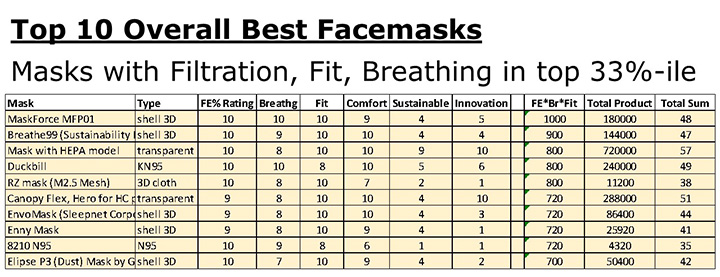

Through this process the wild mess of data that was originally compiled turned into a usable overview table (Figure 5). This provided the ability to compare filtration efficiency versus breathability; sustainability versus filtration efficiency, etc., to determine the bad, better and best masks included in the study.

Study results

As a result of this analysis of the facemask technologies, one durable and one disposable facemask received the highest ratings in respiratory protection. This meant the technology rated high in filtration efficiency and breathability, with very low pressure drop and a very good fit.

The highest-rated durable product was the MaskForce MFP01, which featured an elastomeric mask that fits the face very well and a high-quality filter widely recognized in the HVAC industry, Hollingsworth and Vose’s Trupor, which by itself lasts five years. And this mask featured five filters.

The best disposable mask was from The Nonwovens Institute at North Carolina State University. This mask achieved excellent results in filtration efficiency and breathability, and the masks are tremendously comfortable.

Another aspect of this study looked at innovation. In this area, it was critical to meet the fundamentals of filtration and fit. But another interesting variable that was particularly important to nurses and doctors among others, was the desire to have people see the expressions on their faces, while also being protected from dangerous airborne particulates. Our study identified several transparent facemasks that provide excellent filtration, performance and fit.

Another important innovation was an anti-fake check through QR codes that enabled consumers to verify if the product was actually made by the professed manufacturer and thus meet the advertised performance requirements.

Now let’s look at the sustainability criteria. This criterion evaluated what the product is made from (e.g., recycled plastics, biopolymers or bioplastics); or if it’s reusable or durable – or a combination of the three. Ideally, the mask would have a reusable frame, and then the filter would be a nonwoven made from biopolymers or natural fibers.

Is it possible to obtain a mask that is both safe and sustainable (i.e., environmentally friendly)? There were 10 masks with top filtration performance and eight masks with top sustainability rating, but where were masks that cover both?

One mask that stood out in the sustainability criteria was named SeeUs95 (Figure 6). This mask has a couple filters, one on each side, both of which provided high filtration efficiency. While this mask’s filtration efficiency is measured (repeatedly) at an N95-level, it is not yet certified to the N95 standard or ASTM standards. The manufacturer is working toward these certifications. What set this mask apart was that it was transparent and also medical grade. The replaceable filters are biodegradable and from natural fibers – bamboo, silk, silver, and carbon. The fit was also uniquely well designed with an airtight bubble seal.

Another mask that stood out as a contender for top mask overall in this study was Canopy. (Figure 7) Canopy is slightly different in that its target use includes hospital settings. It has the distinguishing factor of having a head fitting and a splash guard. The Canopy has a transparent front and an airtight seal that won’t irritate the skin, much like SeeUS95, with extensive testing to support its biocompatibility to ensure it won’t irritate the skin. This is an important factor as healthcare workers have found that after wearing masks for long hours, they often have significant skin issues on their face from exposing it to an airtight environment over extended periods of time. The Canopy mask filters at the N95 level.

So, while the study failed to identify a mask that rated highly in all of the 6 criteria that were evaluated there were some promising results. (Figure 8)

Takeaways

The key takeaways from this study are that the facemask technologies of today are capable of providing high filtration efficiency, a really good fit, and easy breathability. However, the market is lacking sustainable products, but there are good approaches and good intents in this area, so there is opportunity and some positive momentum in this area. On the negative side, there are many companies throwing standards and test methods around like confetti without regard for how this information may be misinterpreted by the consumer. Also, companies are, in some cases, hiding necessary performance data behind the veil of proprietary information. Performance data for technologies that are designed to protect the health of the consumer needs to be clearly communicated, and there is much work to be done here to ensure trust and transparency in the marketplace.

To view the complete list of evaluated facemasks along with the detailed analysis or references on each, contact Natasha at natasha@natashadifiore.com.

References

- Anand, S. M. S., 2020. Size distribution of virus laden droplets. Nature, Volume 10, p. 21174.

- Clapp, P. W., Emily E. Sickbert-Bennett, P. M., James M. Samet, P. M. & al, e., 2020. Evaluation of Cloth Masks and Modified Procedure Masks as Personal Protective Equipment for the Public During the COVID-19 Pandemic. JAMA Internal Medicine, 181(4), pp. 463-469.

- Duguid, J. P., 1946. The size and the duration of air-carriage of respiratory droplets and droplet-nuclei. Journal of Hygiene (London), Volume 44, pp. 471-479.

- Lee, B. U., 2020. Minimum Sizes of Respiratory Particles Carrying SARS-CoV-2 and the Possibility of Aerosol Generation. International Journal for Environmental Research and Public Health, Volume 17, p. 6960.

- M.Blachere, F., R.Lemons, A., P.Coyle, J. & D. NotiPaDa, R. C. G. H. G. R., 2021. Face mask fit modifications that improve source control performance. American Journal of Infection Control, 50(2), p. 133.

- Makermask.org, 2019. Improving Mask Fit and Seal. [Online]

- Available at: https://makermask.org/improving-mask-fit-and-seal/

- [Accessed 10 9 2021].

- Neil J. Rowan, R. A. M., 2021. Disposable face masks and reusable face coverings as non-pharmaceutical interventions (NPIs) to prevent transmission of SARS-CoV-2 variants that cause coronavirus disease (COVID-19). Science of the Total Environment, Volume 772.

- Norbert Serfozo, J. O. N. Z. M. L. V. Ž., 2017. Size-Resolved Penetration of Filtering Materials from CE-Marked Filtering Facepiece Respirators. Aerosol and Air Quality Research, Volume 17, pp. 1305-1315.

- Shaji Skaria, G. C. S., 2014. Respiratory Source Control Using Surgical Masks With Nanofiber Media. Annals of Occupational Hygiene 58(6), 58(6), p. 771.

- Stadnytskyi, V. e. a., 2020. The airborne lifetime of small speech droplets and their potential importance in SARS-COV-2 transmission. Proc. Natl. Acad. Sci. of USA, Issue June 2, 2020 117 (22), pp. 11875-11877.

- Stahl, C. F. K. e. a., 2021. Comparison of the Filtration Efficiency of Different Face Masks Against Aerosols. Frontiers in Medicine (Pulmonary Science), Volume 8, p. 654317.

- Steven E. Prince, e. a., 2021. Assessing the effect of beard hair lengths on face masks used as personal protective equipment during the COVID-19 pandemic. J Expo Sci Environ Epidemiol., 31(6), pp. 953-960.