Today, more than ever, there is huge demand for innovative advances in microfiltration. Customers from across the spectrum – including pharmaceutical, food and beverage and health care – rely on precise filtration to produce safe medical therapeutics, extend the shelf life of food without preservatives and to optimize industrial cooling systems, among other applications.

H&V, a global leader in filtration, separator and energy storage solutions, is meeting this demand with its newest product family, Trupor®. Capitalizing on more than two centuries of fibrous porous materials leadership and innovation, Trupor® brings new high performance microfiltration capabilities to membrane buyers. It is the latest example of how H&V’s advanced materials are used in nearly every industry and touch every aspect of modern life. Wherever people work, live or travel, H&V solutions like Trupor® are close by, helping to create a cleaner, healthier, more sustainable world.

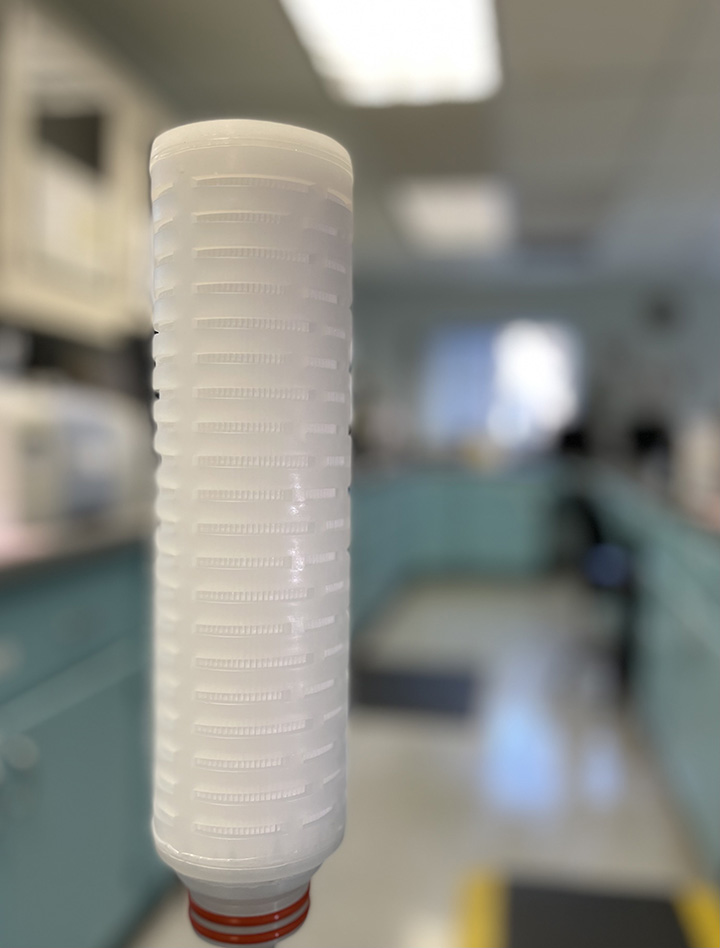

Sold as a rolled good, Trupor® is a patented microporous filtration that delivers membrane reliability with best-in-class flow rates.

The Trupor Advantage®

Prior to developing Trupor®, H&V had introduced superior performance to new air filtration using charged products – TechnoStat™ and AlphaPerm™ are just two examples – but charge was not an option in liquid filtration, which is what drove the novel approach and led to Trupor®’s superior performance.

Sold as a rolled good, Trupor® is a patented microporous filtration that delivers membrane reliability with best-in-class flow rates. It is designed to save both money and time, and its composite structure and superior pore size uniformity deliver long life and stable performance in the thinnest possible efficiency layer.

Trupor® also enables improved flow compared to traditional membranes, leading to lower costs and the ability to filter novel fluid streams. Offered in industry standard materials, Nylon and PES/PBT composites, Trupor® can be used as a final efficiency layer for improved flow or co-pleated as a capacity layer to extend life and reduce change-outs. Trupor® can be also used in both dead-end and cross-flow applications.

High performance

Trupor® offers an array of benefits and features that make it the right choice for microporous filtration.

- Membrane reliability, with industry standard pore sizes and materials.

- Reference cartridges that consistently show twice the flux and nearly twice the capacity of benchmark membranes.

- Compliance with relevant FDA, EMA, NSF and other regulatory guidelines.

- Hydrophilic and hydrophobic versions available.

Partners for growth

Innovation in porous materials requires a thoughtful approach to speed and feedback. H&V has two partners helping to drive the growth of Trupor® in the market: I.W. Tremont and Superior Felt and Filtration.

- I.W. Tremont uses Trupor® in its LabExact brand of products, which are sold through multiple channels worldwide, including Amazon.com. The LabExact product line helps new users of membranes get the benefits of Trupor® faster.

- To distribute Trupor®, H&V chose Superior Felt and Filtration, which runs the largest distribution center for nonwovens in North America and is committed to providing fast, convenient service to customers.

More to come

Trupor® is available today in Nylon with pore sizes of 5.0 micron, 1.2 mm, 0.80 mm, 0.65 mm, 0.45 mm, and 0.20 mm. Other polymer families, using the same polymers already used by microfiltration cartridge buyers, are on the way.

To find out more about Trupor® and how it can help meet your microfiltration needs, visit www.trupor.com.

This content is sponsored by Hollingsworth & Vose.

![Figure 1: Differentiation with membranes based on the famous Robeson diagram that plots selectivity vs. permeability. From Reference. [4]](https://www.filtnews.com/wp-content/uploads/IFN_042023_membranes_Figure1-225x125.jpg)