Founded more than 100 years ago, John Crane is a global leader in rotating equipment solutions, supplying engineered technologies and services to the process industries. The company designs and manufactures a variety of products, including filtration systems, mechanical seals and systems, couplings, and predictive digital monitoring technologies. All accomplished through a global network of more than 200 sales and service facilities in over 50 countries, John Crane technical experts are strategically located in close proximity to customers around the world.

In this edition of IFN’s Executive Q&A, we interview Thomas Grimm-Bosbach, John Crane’s product line director for its Filtration business unit.

Ed Gregor: John Crane is known primarily for mechanical sealing products. Because of the company’s success with sealing products, why is there an interest in filtration?

Thomas Grimm-Bosbach: Process contamination negatively impacts operations, resulting in increased maintenance, reduced production time and unplanned costs. Like the other mission-critical components supplied by John Crane, filtration systems keep operations running at peak performance, extend equipment life and increase operational predictability.

John Crane has been active in filtration supply since 2008 – when the company acquired Indufil – focusing on gas and lube oil filtration for rotating equipment. The addition of filtration systems for widespread rotating equipment complemented our existing product portfolio and added to the range of aftermarket products and services provided to our core customer segments.

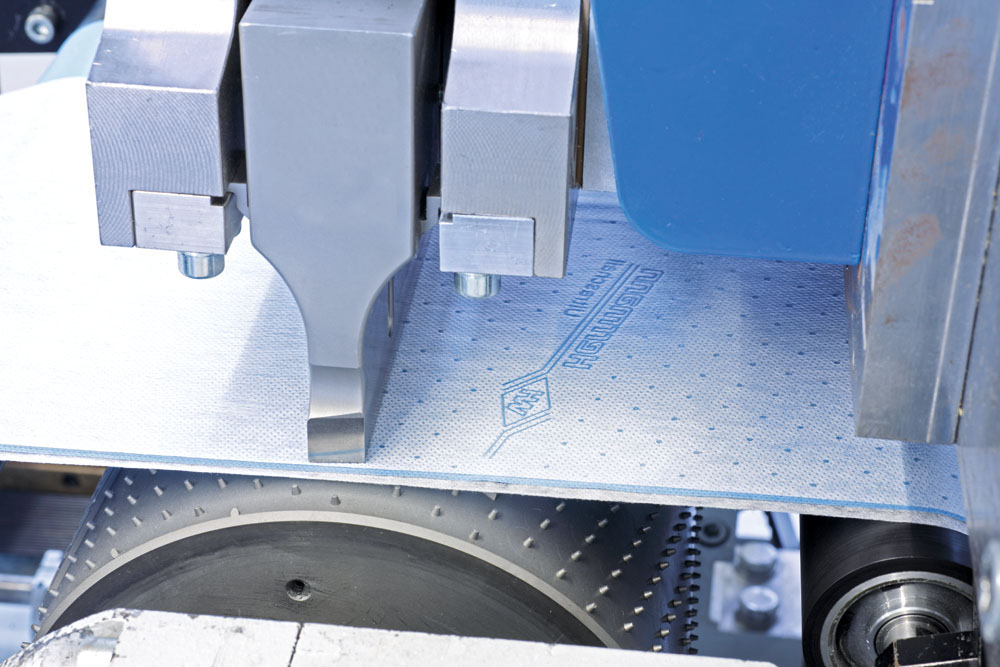

In 2018, John Crane acquired Seebach GmbH, adding additional process filtration elements to our suite of products. We added two new filter element production sites and another development team through the Seebach acquisition, allowing us to further optimize filter systems and elements to customer requirements. By adding new application expertise and breadth to our filtration offering, we can better develop integrated solutions and satisfy our customers’ holistic process equipment requirements.

Ed Gregor: What area or areas of filtration will the company focus on in the future?

Thomas Grimm-Bosbach: John Crane further enhances its technology leadership in energy applications and provides innovative solutions and capabilities to support new applications in mission-critical chemical and process industries. By developing products in new applications, we increase the available market within existing target industries and increase the connection to existing customers.

Ed Gregor: Regarding growth, are you considering acquisitions in filtration, or is John Crane pursuing an organic growth strategy?

Thomas Grimm-Bosbach: John Crane considers both organic and inorganic activities as part of its growth strategy. Many of the industries in which we compete are evolving rapidly, including oil and gas and its downstream industries such as chemical and plastics, so acquiring new technologies is an option.

Ed Gregor: If acquisitions, are you considering domestic or global?

Thomas Grimm-Bosbach: We consider both domestic and global options with a clear focus on market access, technology and media to support our customers worldwide.

Ed Gregor: Are there any particular filtration product areas you are focusing on?

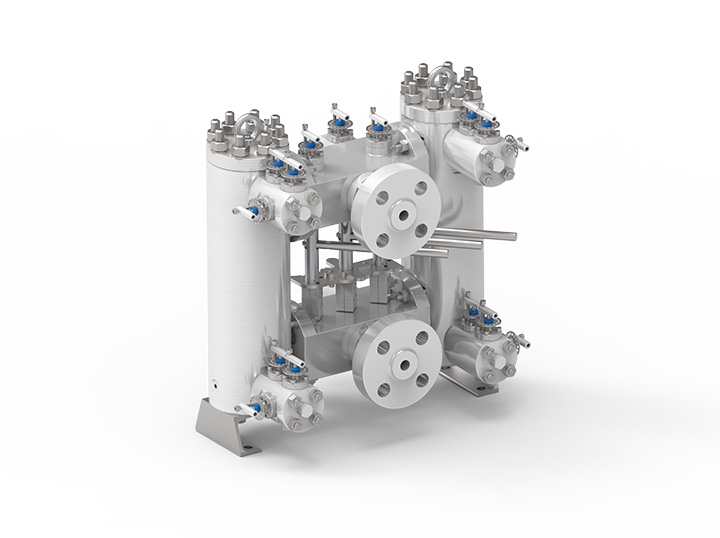

Thomas Grimm-Bosbach: In the coming year, we will launch four new filtration products:

- A high-flow liquid/gas coalescer addressing the problems around burner tip protection in ethylene plants and the protection of molecular sieves in the amine loop

- An automatic backflush filter for the reduction of water consumption in the pulp and paper and mining industries

- A liquid/liquid coalescer for the removal of water from fuels

- A varnish removal filter to extend the lifetime of lubrication oil around rotating equipment

- These new products will significantly contribute to reducing our customers’ carbon footprint and help to reduce the consumption of valuable natural resources.

Ed Gregor: Has John Crane joined any filtration industry trade organizations as part of its growth strategy?

Thomas Grimm-Bosbach: Since 2019, John Crane has been a corporate sponsor of the American Filtration Society (AFS), an advocate for filtration in North America that offers educational initiatives and networking opportunities within the filtration industry.

Ed Gregor: In the areas where John Crane is active in filtration, what market trends do you see occurring?

Thomas Grimm-Bosbach: Market trends strongly depend on the industry and the region we are looking at. In general, we expect the market to recover from COVID-19-related downturns, but the baseline is very different. The recent growth in the pharmaceutical industry is expected to reduce once more, as investments will be directed into other areas. As we recover from the pandemic, the same will be true for the part of the polymer industry whose products mainly go into packaging for online purchases. In contrast, the refining industry will see an uptick as many refineries that closed begin to reopen.

John Crane will focus on industries and application areas where we can contribute to reducing greenhouse gas emissions, preserving our natural resources, and a sustainable energy transformation.

For questions related to this interview, please contact Paul Hulme, business development manager, John Crane Filtration, North America, at paul.hulme@johncrane.com.