We take for granted one of the most basic resources for life in general and every human being – clean air.

TALAMON filter technology is used to realize this requirement. Wherever conventional filtration reaches its limits, TALAMON solutions are in their element.

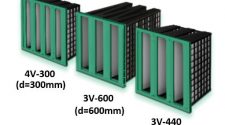

TALAMON’s portfolio includes open-pored foam filter media in various thicknesses and weights per unit area and pleatable flat media with up to five functional layers with a wide variety of functional particles embedded in between, such as synthetic spherical activated carbons and spherical ion exchangers, granulated activated carbons, variants impregnated against a wide variety of harmful gases, as well as other customer-specific sorption materials. Our pleatable flat media can be laminated with a wide variety of nonwovens for particle and aerosol separation.

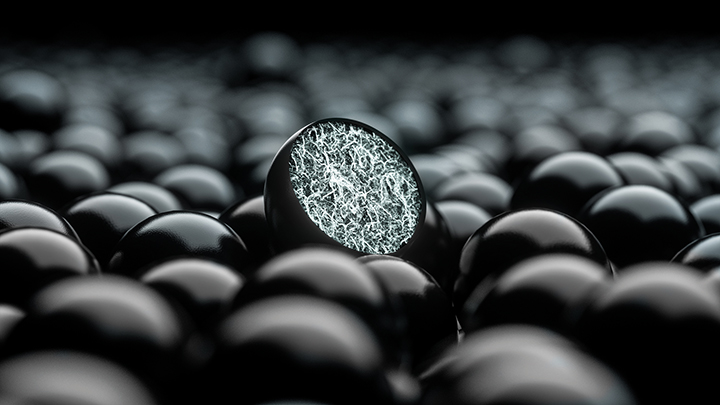

For our foam filter media and components, the inner surfaces of open-pored reticulated polyurethane foams are provided with a special adhesive and a wide variety of functional particles. This results in a solid, very air-permeable filter material with a very high sorbent weight. By choosing the type of sorbent and the foam porosity, almost all adsorptive problems can be solved.

For TALAMON flat media a textile carrier, usually a spunbond, is sprayed with special adhesive threads to create a fine adhesive web. This is then immediately applied with the sorbents intended for the respective product. This creates a first monolayer, which can be covered with a second monolayer of the same sorbent or another sorbent in the next step.

Our technology enables us to manufacture structures of up to five layers, and in individual cases even more.

Exemplary applications

Medicine

Filter technology for medical equipment such as operating lasers, high-frequency scalpels to protect patients and operating personnel are just some of the many applications in the medical field.

Cleanroom

Filter media for the highest level of air quality in microchip production environments. Highest performance and outgassing-free sorptive composite materials are required.

Breathing air

TALAMON filter media, mainly in the industrial sector, guarantee the highest level of protection, convenient applicability, and at the same time low breathing resistance.

Household

Disturbing odors during cooking are no longer removed by kitchen hoods, which blow air to the outside and thus waste heating costs. They are removed in recirculation bonnets equipped with TALAMON foam filter technology or filter units on the kitchen ceiling.

Special applications

The production of customized filter media is our ambition. No matter what challenge you have regarding the removal of molecular gaseous contaminants, TALAMON filter media are the solution.

Automotive

According to DIN EN 15695, Cat 4, pollutants introduced through the outside air, such as pesticides and other plant protection agents in agricultural machinery, must be removed. The situation is similar for landfill vehicles, where many environmental toxins are transported into the cabin through the outside air.

TALAMON GmbH produces all core components exclusively in its own factory in Germany. The entire production process from the use of raw materials to complex system solutions is in one hand and is constantly monitored and controlled.

This content is sponsored by TALAMON Filtration Technologies

Visit us at FILTECH: Hall 7, Stand M31