3rd Year Ph.D. Student

Virginia Commonwealth University, Mechanical and Nuclear Engineering Porous Media and Multi-Phase Flows (PMMF) Laboratory

Mohammad Jamali is pursuing a Ph.D. in Mechanical Engineering at Virginia Commonwealth University, where he is conducting research on understanding droplet mobility and penetration in nonwovens via numerical simulation and complementary experiments at the Porous Media and Multi-Phase Flows (PMMF) Laboratory. His project is supported by The Nonwoven Institute at North Carolina State University.

After finishing his undergrad study in Mechanical Engineering, he passionately started his master’s degree program to developed new ideas and methods for solving challenging practical problems, such as heat transfer and fluid mechanics. He joined the Mechanical and Nuclear Engineering Ph.D. program at Virginia Commonwealth University in 2016. He has done a series of experiments and computer simulation in order to understand and formulate droplet mobility, adhesion and penetration for parallel and orthogonal fibers as his Ph.D. thesis.

Research overview

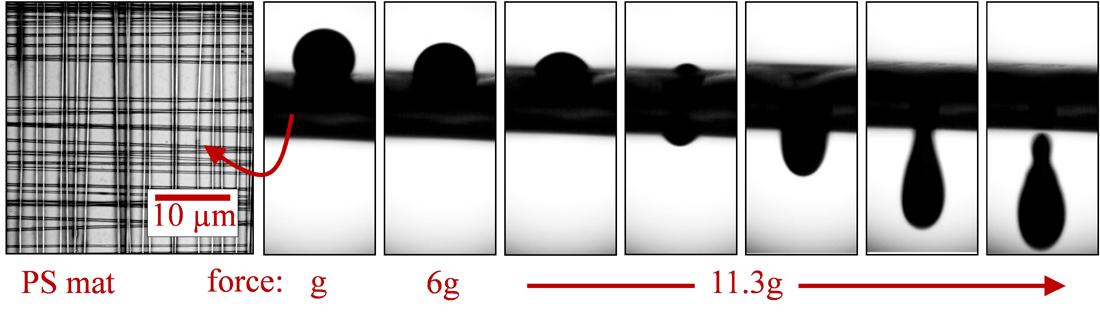

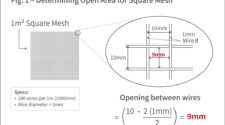

Jamali’s research is focused on mobility of a droplet on a nonwoven surface, which depends on the local wetting state of the surface underneath the droplet. These wetting states include the Cassie state, the Wenzel, the Rose Petal state, and the Gecko state. At a high level, it is the droplet area of contact with the solid surface and the nature of the contact that determines the mobility of a droplet on a nonwoven fabric; the droplet contact angle is not the independent variable in this problem. For instance, it is quite possible that a droplet forming a contact angle of 100 deg with a particular nonwoven rolls off the surface a lot faster than the same droplet does on another nonwoven with which it forms a contact angle of 140 deg. The question to answer here is how a surface can be designed to repel water (or oil) to remain clean not just initially but over time. Similarly, the penetration of a water droplet into a hydrophobic nonwoven (or an oil droplet into an oleophobic nonwoven) is not understood well. For instance, a water droplet may initially bead up on the surface of a hydrophobic nonwoven, but the very same droplet may penetrate into the structure over time (due to evaporation, as evaporation increases the pressure inside a droplet) or upon impact with the surface. These findings are compelling because they illustrate that understanding droplet penetration is critical for water-resistant membranes, wound dressing and functional textiles, and fog harvesting.

These findings are compelling because they illustrate that understanding droplet penetration is critical for water-resistant membranes, wound dressing and functional textiles, and fog harvesting.

Jamali’s project can be of great interest to industry as it develops a series of experimental and computational tools that can be used for characterizing the behavior of a nonwoven interacting with a fluid. Industries that directly benefit from this research include, but are not limited to, protective clothing (“phobic” nonwovens resisting fluid penetration), absorbent media such as diapers (“philic” nonwovens promoting fluid absorption), fluid–fluid and fluid–air separation media (“philic” to one phase, “phobic” to the other), fuel cells (gas diffusion layer).

Career goals

Jamali is aiming to complete his Ph.D. this year. The results of Mr. Jamali’s research on droplet mobility has already led to four published papers, which appeared in Colloids and Surfaces A, Langmuir, and Applied Surface Science, Journal of Applied Physics, respectively. He has also published papers from a different research project on heat transfer and entropy generation analysis of nanofluid flow inside annuli in Applied Thermal Engineering and the Journal of Central South University. While most researchers publish their work in some capacity, few are able to consistently showcase their work in such respected journals.

In the future, Jamali intends to research, develop and test methods for fluid and thermal systems to improve his problem-solving ability in fluid and solid mechanics.

For details on how to submit yourself or a student you know for consideration as a “Student Spotlight” in IFJ, contact Matt Migliore at mmigliore@inda.media or +1 919.459.3754.