The use of flame retardants is a societal conundrum. The need to protect human life and property from fire is the foundation for the use of flame retardants. The protection of human life also brings into consideration the sustainable environmental impact that flame retardants may present. Balancing the chemistry to protect human life in a sustainable manner is the challenge that everyone must embrace.

Antimony and halogens (bromine and chlorine) have been used for several decades as cost-effective flame retardants. In recent times, these chemistries have drawn the attention of groups concerned primarily with the impact on mankind’s health because of environmental concerns. As new chemistries are developed, there may be tradeoffs in terms of efficiency, cost, and performance; however, the protection of human life must be the primary focus when developing new consumer products.

Many governments will continue to mandate or legislate additional flame retardant standards for filters or environments where filters are used. History has shown that the flame retardant standards continue to evolve to more stringent requirements and/or additional requirements to guide manufacturers to provide the best technology to better protect the end users. Additionally, the litigation environment is another driver that is affecting the demand for more products to meet current and future flame retardant standards. Manufacturers can’t simply state that their products contain a flame retardant – the filters must meet specific flame retardant test standards over the life cycle of the filters.

Flame Retardants for Filtration Media

While there is still demand and a place for low-cost flame retardant salts, non-durable flame retardant coatings, and flame retardant coatings containing heavy metals and halogens, companies concerned with producing sustainable filtration media are moving forward with new sustainable chemistries. Stahl currently has multiple flame retardant additives and coatings that have been designed specifically for filtration media manufacturers who are focused on developing new sustainable filtration media. Although these products have been designed for 100% cellulosic media, they can also be used on some cellulosic/synthetic blends.

Additional R&D work is focused on bio-based chemistries, polymeric fire retardant systems, synergistic action between sustainable elemental chemistries. Stahl has already successfully incorporated bio-based chemistries in several polymers (as recognized by the EcoVadis Platinum award) and this provides a basis for the development of the next generation of sustainable polymers that can be used in the filtration market. Looking “outside the box” at other elemental synergies is a deep dive that must be taken to allow the filtration market to meet the sustainable goals of the most forward-thinking companies in the filtration industry. This approach will result in market-changing criteria within the filtration market that will provide the end user with an environmental friendlier filter.

The long-term use of antimony-bromine fire retardant chemistries for filtration media is coming to an end due to the environmental concerns attributed to antimony and bromines. Whether we agree with the conclusions attributed to these chemistries, Stahl is committed to developing and providing the sustainable fire retardant chemistries that will meet the needs of the filtration market. Balancing the performance requirements along with the economics and sustainability demands is a challenge that is best suited for an integrated approach with individual filter media manufacturers and end uses. During this transitional phase, Stahl still provides conventional flame retardant additives and coatings.

The fitness for use requirements, such as fire retardancy, pleatability, pleat retention, high temperature exposure to in-service environments, water resistance, color, stiffness, dust holding ability,

pressure drop, etc. are best addressed individually for specific end uses. Filter manufacturers must also be a part of the decision-making process in addressing the conversion to the new sustainable flame retardant coating systems to allow the best fit chemistries for their specific needs. With an understanding that this transition will likely require modifications to the fitness for use criteria or pricing structure, the filtration industry can move forward with more sustainable filters.

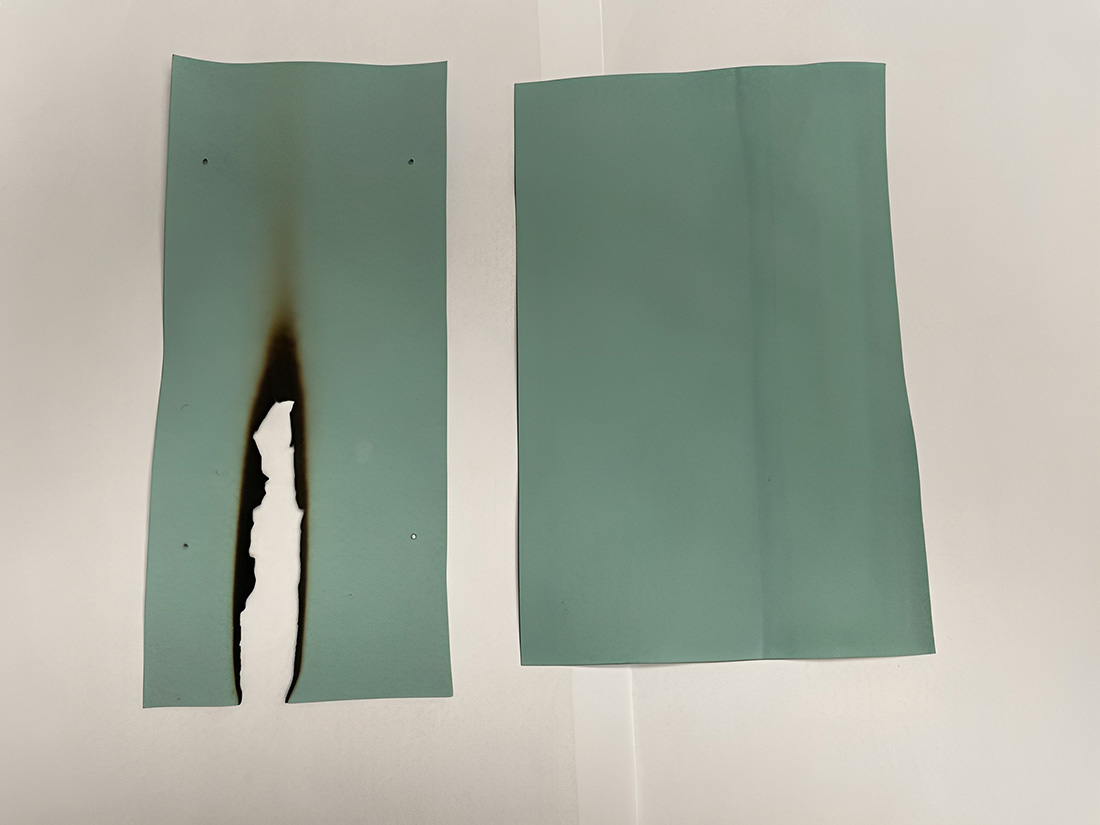

The new filtration media must have a visual identifier that all can see that separates the sustainable filters from the conventional filters. This will provide end users the ability to easily identify the

sustainable filters from the conventional filters and thus allow the market to dictate the desire and speed at which the filtration industry moves to the new sustainable filters.