The Importance of Face Velocity and Its Impact on Filter Parameters and the Role of Inertial Impaction on Larger Particle Size

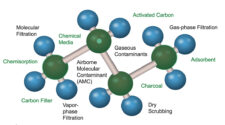

The concern over indoor air quality is a pressing issue in today’s world, largely driven by the ever-expanding industrial landscape and the increasing use of innovative products and materials. Inhaling air pollution particles exposes individuals to significant health risks, including cardiovascular and respiratory problems that could potentially lead to a shortened lifespan. Its primary role is to mitigate the presence of fine particles, within indoor environments. However, a persistent challenge lies in filtration: the substantial pressure differentials that arise across multiple filter layers, subsequently resulting in elevated energy consumption. The goal in filtration system design is to strike a delicate balance between reducing these pressure differentials, maintaining filtration efficiency, and prolonging the lifespan of filters. This pursuit is fundamental for achieving energy-efficient and cost-effective building operations. Filtration hinges on several core mechanisms for trapping particles, including interception, inertial impaction, diffusion, and sieving. The size of particles being filtered is a key factor in determining which mechanism takes precedence in the filtration process. Yet, it’s important to note that each filtration mechanism can be significantly influenced by the face velocity of the filter, an essential parameter with far-reaching impacts on filtration performance. Notably, in the case of nanofiber filters, the pressure differential decreases proportionally with the face velocity, not aligning with Darcy’s Law, this is due to the slip flow effect. Researchers have delved into the effects of velocity profiles on pleat geometry, which, in turn, affects the initial local collection efficiencies. Investigations have also explored the determination of filter pleat geometry based on maximum local velocity. Furthermore, studies have assessed how filter media characteristics influence the efficiency of HEPA filters. Notably, it has been observed that efficiency tends to decline as face velocity increases, primarily due to the reduced time particles spend in contact with nanofiber filters, shedding light on the intricate relationship between face velocity and filtration performance. Studies have further revealed that the specific resistance and density of the dust cake tend to be higher at higher filtration velocities, particularly when the dust concentration remains constant in the case of bag filters. These findings underscore the importance of considering filtration velocity as a pivotal factor in the quest for more efficient and effective filtration systems. This critical factor profoundly affects the overall performance of filtration systems, notably impacting both the pressure differential and efficiency.

To delve deeper into the concept of inertial impaction, it’s important to understand how this phenomenon takes center stage in filtration. Inertial impaction occurs when high air velocity imparts a substantial force of inertia on particles suspended in the air.

The Impact of Face Velocity Over Filter Parameters

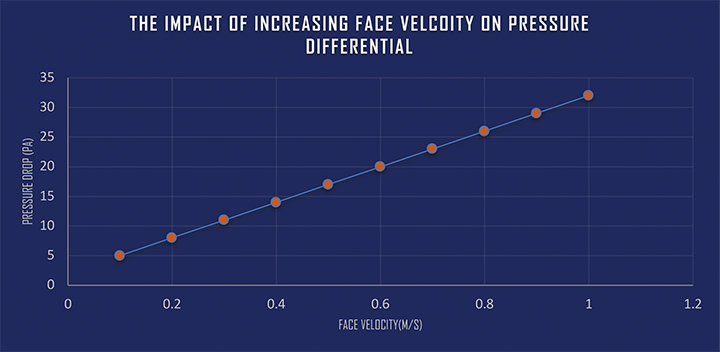

Pressure Differential and Face Velocity

At the heart of understanding the significance of filter face velocity lies the concept of the pressure differential, often referred to as pressure drop. In filtration systems, this pressure differential is the dominant indicator of performance, and it is intimately linked with the filtration velocity. The basic principle is simple: the higher the face velocity, the greater the pressure drop as seen in Figure 1. As the airflow speed increases, so does the resistance to the movement of air through the filter. This dynamic manifest itself as an essential consideration for anyone seeking to optimize filtration systems for a range of applications.

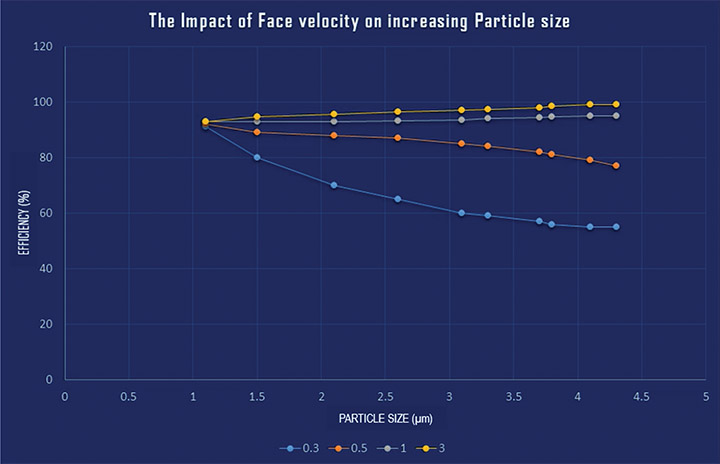

Efficiency and Face Velocity

Efficiency is a central concept in filtration, defining a filter’s ability to capture and retain particles from the air passing through it. The relationship between efficiency and face velocity is multifaceted, primarily driven by particle size. In essence, the efficiency of a filtration system can be greatly influenced by the speed at which air moves through it. The interplay between face velocity and efficiency showcases a complex relationship, where smaller particles may encounter reduced efficiency at higher face velocities, while larger particles tend to benefit from the increased airflow. Understanding this dynamic is pivotal in designing and selecting filters that can effectively address specific filtration needs while optimizing energy consumption and prolonging filter longevity.

Smaller Particle Sizes (<0.5µm)

When it comes to smaller particles, those with a diameter less than 0.5µm, a higher face velocity can pose challenges to filtration efficiency. These tiny particles have less time to interact with the filter media due to the swift airflow, increasing the likelihood of them slipping through the filter’s defenses. This is particularly important to note since smaller particles can include various contaminants, some of which may be harmful to health or the environment.

Larger Particle Sizes

On the flip side, larger particles tend to thrive under higher face velocities. This seemingly counterintuitive phenomenon is primarily attributed to the principle of inertial impaction. With greater air velocity, the particles gain substantial inertia, increasing the probability of collision between particles and the filter media fibers. This collision results in efficient particle capture, a testament to the effectiveness of inertial impaction as a filtration mechanism. As a result, efficiency tends to rise for particles of larger sizes when exposed to higher face velocities.

To delve deeper into the concept of inertial impaction, it’s important to understand how this phenomenon takes center stage in filtration. Inertial impaction occurs when high air velocity imparts a substantial force of inertia on particles suspended in the air. This force becomes increasingly significant as the face velocity rises, creating a higher likelihood of collision between particles and the filter media fibers. In practical terms, this means that larger particles, which possess greater mass, are more likely to collide with the filter media fibers, leading to successful capture and removal. The result is a boost in filtration efficiency, particularly when dealing with particles in the larger size range. This principle underscores the critical importance of face velocity not only in terms of efficiency but also in the application of filtration technology across various industries and scenarios.

The relationship between face velocity and efficiency is not uniform across all particle sizes. This complexity arises from the interplay between inertial impaction and particle size. Smaller particles, due to their limited mass and inertia, struggle to interact with the filter media effectively at higher face velocities. As a result, filtration efficiency for these particles tends to decline as face velocity increases as seen in Figure 2. This presents a challenge in situations where capturing small particles is of utmost importance, such as in cleanrooms or environments that demand stringent air quality standards. Conversely, for larger particles, the dynamics shift dramatically. The increased face velocity imparts a powerful force of inertia, effectively enhancing the chances of particle-media collisions. This translates into an upswing in filtration efficiency for larger particles at higher face velocities.

ISO16890 Testing: Unveiling the Trends

The trends discussed here are not mere conjecture; they are consistently observed and quantified through standardized testing methods. One such standard, ISO16890, serves as a critical framework for assessing filter efficiency. In ISO16890 testing, particles ranging in size from 0.3-10µm are employed as the test media. This size range is carefully selected to encompass the variety of particles commonly encountered in real-world filtration scenarios. The data obtained from ISO16890 testing provides critical insights into how filters perform under different face velocities. It highlights the essential role of face velocity in influencing filtration efficiency across the spectrum of particle sizes. It is clear that smaller particles often face reduced efficiency at higher face velocities, while larger particles reap the benefits of inertial impaction, resulting in improved efficiency.

Finding Significance

The importance of filter face velocity in filtration performance cannot be overstated. It is a key parameter that directly impacts both the pressure differential and efficiency of filtration systems. The interplay between face velocity, particle size, and the principle of inertial impaction reveals a dynamic and often counterintuitive relationship. Moving forward in the realm of filtration technology, understanding these intricacies is crucial. Whether it is concerned with indoor air quality, optimizing HVAC systems, or ensuring compliance with industrial air filtration standards, comprehending the effects of face velocity on filtration performance is fundamental. It allows us to make informed decisions, striking a balance between capturing the full spectrum of particles and ensuring the efficient operation of filtration systems. The journey to harnessing the power of inertial impaction and face velocity in filtration is a voyage into a realm where science, engineering, and practical applications converge to create cleaner, healthier, and more efficient environments for all.