In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Matt Migliore at mmigliore@inda.media.

Most recent update: October 27, 2020

Hollingsworth & Vose adds capacity for its Technostat electret filtration media in Germany

Hollingsworth & Vose announced a major capacity expansion of its Technostat electret filtration media products in Hatzfeld Germany, beginning in the second half of 2021. Technostat is a high-performing electret filter media for Cabin Air, HVAC, Air Purifier, and other Indoor Air Quality (IAQ) applications where high filtration efficiency and low pressure drop are required.

H&V’s unique and proprietary Technostat products have played a direct role in fighting the COVID-19 pandemic in ventilator, respirator, and other critical medical applications. With the latest Hatzfeld investment, H&V is further improving its global Technostat manufacturing footprint, which already includes Kentmere, England and Floyd, Virginia.

Source: hollingsworth-vose.com

Scientists urge U.S. Congress to protect military from PFAS exposure

A group of 42 scientists submitted a letter to leaders of the House and Senate Armed Services committees calling for a ban on military purchasing of certain consumer products with per- and polyfluorinated substances (PFAS). This would be accomplished by including a provision in the National Defense Authorization Act (NDAA) for FY 2021 that prohibits the Defense Logistics Agency from buying products with non-essential uses of PFAS. This includes food packaging, cookware, cosmetics, sunscreens, dental floss, furniture, and carpeting.

“Due to the Department of Defense’s past use of fire-fighting foam with PFAS, some of the most contaminated groundwater in the country is found at military bases,” said Tom Bruton, a Senior Scientist at the Green Science Policy Institute. “The 2020 NDAA took the critical step of phasing out PFAS in military fire-fighting foam. This provision would further protect service members and their families by reducing other routes of exposure to these toxic chemicals.”

PFAS are associated with serious health problems including kidney and testicular cancer, thyroid disease, decreased sperm quality, high cholesterol, and decreased response to vaccines. Because of these health harms and the chemicals’ extreme environmental persistence, a landmark consensus statement signed by more than 200 scientists in 2015 endorsed moving away from non-essential uses of PFAS.

All of the products impacted by the provision are available without PFAS. For example, retailers like Home Depot only sell carpets and rugs without PFAS. The vast majority of cosmetics and sunscreens are made without PFAS.

“With its mighty purchasing power, the military can lead the way in preventing the use of PFAS at its source—in products,” said Arlene Blum, Executive Director of the Green Science Policy Institute. “We can’t get rid of the PFAS pollution in our lakes and rivers, but we can stop adding to it. To get out of a hole, the first step is to stop digging it deeper.”

Source: greensciencepolicy.org

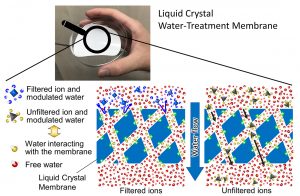

Researchers discover how water can affect its own filtration

Membranes with microscopic pores are useful for water filtration. The effect of pore size on water filtration is well-understood, as is the role of ions, charged atoms, that interact with the membrane. For the first time, researchers have successfully described the impact water molecules have on other water molecules and on ions as part of the filtration mechanism. The researchers detail a feedback system between water molecules, which opens up new design possibilities for highly selective membranes. Applications could include virus filters.

Synthetic chemistry is a field of study related to the creation and exploration of new substances and materials that do not exist in nature. Sometimes a specific property or behavior of a material is required for an application such as pharmaceutical or high-tech manufacture. Synthetic chemistry can help find, create or refine suitable materials. For example, so-called synthetic liquid crystal membranes could be used for water filtration.

When filtering water or other liquids, the aim is to separate chemical components, such as ions, from your target fluid. Use of a porous membrane can be the primary method for doing this. It’s intuitively obvious that holes in a surface will stop anything larger than the hole from passing through. But advanced membranes like synthetic liquid crystal membranes can have pores that are barely a few nanometers, billionths of a meter, across. At these scales, there’s more to membrane functionality than just the size of a pore.

“Chemistry plays a big part in what happens at these small scales,” said Professor Takashi Kato from the Department of Chemistry and Biotechnology at the University of Tokyo. “In the case of water filtration, the pores are sized to let nothing larger than water pass through. However, there are also electrostatic forces between ions and pores. If the material is engineered correctly, these forces serve as a further barrier to ions even if they’re smaller than the pores. This is fairly well-understood. But there is yet another important substance at play that can impact water filtration, and that’s actually the water molecule itself.”

Read the full story: https://www.u-tokyo.ac.jp/focus/en/press/z0508_00132.html

Source: u-tokyo.ac.jp/

Yale researchers develop chlorine-resistant membrane for RO filtration

The journal Nature Sustainability published a study by Menachem Elimelech, professor of chemical and environmental engineering at Yale, and his research team on their development of a multilayer polyester membrane that is resistant to degradation by chlorine. This discovery could provide a more sustainable, lower-cost alternative to conventional membranes.

“The exciting component is that we’ve been able to develop a membrane that not only has performance, that is up to reverse-osmosis standards, meaning high salt rejection and high water permeability, but we’ve done so using chemistry that is also chlorine resistant,” said Ryan DuChanois GRD ’23, a doctoral candidate in chemical and environmental engineering and a member of Elimelech’s team. “To our knowledge, that hasn’t been done before.”

Polyamide has conventionally been used for RO membranes due to its ability to withstand a greater range of temperatures and pH levels in comparison to its alternative, cellulose acetate.

However, polyamide is intolerant to chlorine, which is used to treat wastewater before the filtration process. As such, the new material developed by Elimelech’s team marks a potential advance for RO membrane filtration.

Read the full story: https://yaledailynews.com/blog/2020/10/19/how-swimsuit-material-inspired-the-holy-grail-of-water-filtration/

For more about the Elimelech Research Group: https://elimelechlab.yale.edu/

AFS announces October/November webinar lineup

The American Filtration and Separation Society (AFS) announced a new lineup of webinars for the months of October and November. The programs include sessions on reverse osmosis, membrane separation technology and 3D printing within the filtration industry. Registration for members is $195 and for nonmembers is $295. The lineups includes:

Tuesday, October 27, 2020, 9:00 am – 11:00 am – CST, USA

Reverse Osmosis Membrane Technology

By Peter Cartwright, Cartwright Consulting

Tuesday, November 10, 2020, 9:00 am – 11:00 am – CST, USA

Membrane Separation Technologies for Non-Biological Wastewater Treatment

By Peter Cartwright, Cartwright Consulting

Tuesday, November 17, 2020, 9:00 am – 11:00 am – CST, USA

Metal Additive Manufacturing (3D Printing) within the Filtration Industry

By Neil Burns, Croft Filters

Wednesday, November 18, 2020, 9:00am – 11:00 am – CST, USA

Membrane Separation Technologies for Biological Wastewater Treatment

By Peter Cartwright, Cartwright Consulting

Source: afssociety.org

Veolia North America secures three municipal water contracts in St. Michael, Albertville and Hanover, Minn.

September was a good month for VNA’s Municipal Water Division in the State of Minnesota, where the company renewed three municipal contracts and added a new one.

Though the three contracts that were renewed were not due to expire until the end of the year, VNA said the customers were so satisfied with VNA’s performance that they wanted to lock up the renewals ahead of time.

The newest contract calls for VNA to provide labor to operate and maintain the Chisago Lakes Joint Sewage Treatment plant in Chisago City, outside Minneapolis. The plant serves the communities of Chisago City, Lindstrom, Wyoming, Center City and Stacey. Terms of the contract call for VNA to be paid roughly $3.75 million over the next five years. VNA’s bid was selected amidst heavy competition from at least three other service providers. Cook said his team has already begun implementing long-needed upgrades such as digitized record-keeping and preventative maintenance programs.

The three Municipal Water contracts that were renewed:

- In Hanover, VNA was awarded a three-year renewal for $274,000 to continue overseeing the town’s collection and distribution system. VNA has been in partnership with Hanover since 1996.

- In St. Michael, VNA was awarded a three-year renewal for $3.175 million to continue operating and maintaining the town’s water and wastewater collection and distribution system, including a wastewater treatment plant with a capacity of 2.5 million gallons per day. VNA has been in partnership with St. Michael since 1996.

- VNA also secured a three-year, $1.9 million renewal with the Joint Powers Water Board groundwater treatment plant, serving the communities of St. Michael, Albertville and Hanover. The plant has a capacity of 10 million gallons per day. VNA has been in partnership with the Joint Powers district since 1998.

Source: veolianorthamerica.com

Sofi Filtration closes on EUR 3 million funding round

Sofi Filtration announced the closing of a EUR 3 million funding round led by Emerald Technology Ventures and joined by Voima Ventures. This is the first investment of Emerald’s recently announced water innovation impact fund. As part of this transaction, Helge Daebel, Emerald Partner for water activities, has joined the board of Sofi Filtration. Alongside the primary transaction a secondary transaction was conducted with selected investors including Loudspring.

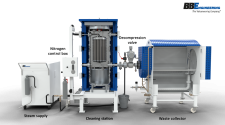

“Sofi Filtration offers a unique, rugged, low-touch and very efficient filtration system for several large industrial markets that are facing significant challenges,” comments Helge Daebel. “Examples are upstream mining and oil & gas production processes, where the amount of water needed per unit of materials extracted increases, while fresh water availability decreases. In combination with strong regulatory pressure, the demand for higher recovery of resources, including water, increases, resulting in an impressive market pull for Sofi Filtration’s solutions. We therefore look forward to working with the company to further capture its market potential.”

Sofi Filtration CEO Ville Hakala explains: “For a number of years, now Sofi Filtration has developed its processes to effectively enter new markets and has established brand awareness as the go-to technology, when it comes to automatically self-cleaning microfiltration. To address the tremendous growth opportunities, we set ourselves out to find the best investors in our specific field of business. With this financing round, we will have the resources to grow our business to the technology’s full potential.”

Source: sofifiltration.com

Koch Separation Solutions to provide membrane filtration in support of ADM’s water & wastewater sustainability initiatives

Koch Separation Solutions (KSS), a global leader in membrane filtration and ion exchange technology, announced it continues to build its relationship with ADM, a leader in agricultural origination and processing solutions. Central to ADM’s philosophy and operations is its commitment to sustainability, and KSS will serve as an ADM preferred vendor for water, wastewater, and in-process separations applications. The relationship is intended to help ADM meet and exceed sustainability and business objectives by improving its processes, conserve water, and protect the environment.

KSS has been working with ADM on a variety of applications, many of which aim to successfully meet tighter discharge limits and/or recover water affecting their production plants. Designs of these applications, which were developed in collaboration with ADM’s Utilities Center of Excellence and KSS Process Engineering, have proven successful when piloted at ADM sites using a variety of membrane configurations. Most recently, ADM’s joint venture Stratas facility purchased a KONSOLIDATOR 544 FEG PLUS tubular Ultrafiltration system from KSS to treat oily wastewater prior to discharge. The system will operate under modified batch mode to retain oil for potential rendering and water for discharge and/or recovery. Additional projects are underway using the PULSION MBR membrane modules to treat wastewater from ADM’s production facilities and purify water for a variety of plant processes.

Source: kochmembrane.com

Mann+Hummel acquires helsa Functional Coating, enhancing elastomer and activated carbon position

Mann+Hummel Group has acquired helsa Functional Coating on September 21st, 2020. This business unit of the helsa group, founded in 1947, complements Mann+Hummel’s portfolio particularly in the area of elastomer and activated carbon technology for special industrial applications. Terms of the acquisition were not provided.

“The takeover will enable Mann+Hummel to position itself as a technology leader in this growth market and further set the company up for the future. This is a further step towards achieving our vision ‘Leadership in filtration,’” explained Emese Weissenbacher, Mann+Hummel’s executive vice president and CFO. “The helsa Functional Coating division has a similar corporate culture since it belonged to a family business also with a long history. We are very much looking forward to working with our new colleagues.”

“For us, as a niche provider of intelligent premium solutions in molecular air filtration, the takeover holds great potential,” said Norbert Gregor, CEO of helsa Functional Coating and future Vice President & Managing Director Molecular Filtration at MANN+HUMMEL. “MANN+HUMMEL’s global infrastructure will enable us to accelerate our growth trajectory and step up our efforts in large-scale projects to reduce molecular emissions worldwide.”

Strengthening the workforce with highly qualified employees, particularly in the area of research and development, a broad product pallet and additional production capacity will help MANN+HUMMEL to increase its competitiveness and offer customers valuable additional benefits.

Source: airfiltration.mann-hummel.com

Caterpillar to acquire Weir Oil & Gas

Caterpillar Inc. has signed an agreement to acquire the Oil & Gas Division of the Weir Group PLC, a Scotland-based global engineering business. Headquartered near Fort Worth, Texas, Weir Oil & Gas produces a full line of products for oil & gas applications.

The purchase price of $405 million is to be paid in cash at closing. The acquisition requires approval by Weir shareholders and is subject to review by various regulatory authorities as well as customary closing conditions. The transaction includes more than 40 Weir Oil & Gas manufacturing and services locations and approximately 2,000 employees.

“We are pleased to have reached this agreement. Caterpillar is a great new home for Weir Oil & Gas, its world-class people, products and services,” said Jon Stanton, Weir Group CEO. “It will enable Weir Oil & Gas to continue to flourish, ensuring the business remains at the forefront of innovation and customer service in the future.”

Morgan Stanley & Co. LLC is serving as Caterpillar’s exclusive financial advisor for the transaction.

Source: caterpillar.com

Lydall to provide meltblown filtration media to participants in ‘Next-Gen Mask Challenge’

Lydall, Inc., a leading global manufacturer of value-added engineered materials and specialty filtration solutions, today announced its partnership with XPRIZE, a nonprofit organization that uses global competitions to crowdsource solutions to some of the world’s biggest challenges. Lydall will supply fine fiber meltblown filtration media, the critical component of N95 respirators and surgical masks that traps harmful particles, to the 25 qualified teams of XPRIZE’s Next-Gen Mask Challenge. Launched in July 2020, this four-month challenge invites young adults around the world to develop the next generation of surgical-grade consumer facemasks. In addition to sharing a one-million-dollar prize, the three winning teams will be connected to rapid manufacturing opportunities in the U.S. to bring their designs to life.

Participants in XPRIZE’s Next-Gen Mask Challenge are tasked with designing face masks that offer a level of performance comparable to that of a surgical mask. This means that the mask must block 95 percent of particles while letting in enough air to allow the wearer to breathe comfortably. Lydall’s meltblown filtration media enables mask manufacturers to meet rigorous standards for quality and efficiency set in the U.S. by NIOSH, a division of the CDC, and ASTM. The material is even imbued with an electric charge that attracts particles, keeping them away from the wearer’s nose and mouth.

Source: lydall.com

Waterloo Filtration Institute to present Annual Conference with a focus on IAQ & COVID-19

The Waterloo Filtration Institute (WFI) will present its 2020 Annual Conference, December 15-16, 2020, 8:00 am -12:00 pm EST. The theme of the event will be “IAQ Health and Safety Solutions Associated with COVID-19”. It will address the critical roles of facemasks and air filtration during the current pandemic for public health and safety.

The virtual conference will feature the following four sessions:

1. Emerging Challenges and Responses

2. IAQ and the Built Environment

3. Facemask Technologies and Latest Developments

4. Facemask/Air Filter Test Methods and Standards

The event will feature 16 distinguished speakers from academia and the industry to share their latest developments and trends on IAQ health and safety solutions in response to the pandemic.

WFI is dedicated to supporting the growth of the global filtration industry and the advancement of filtration and separation processes for a clean, healthy, and sustainable world.

For full program details and to register, visit wficonference.org.

NWI’s spunbond high-efficiency filter media wins RISE Innovation Award

More than 150 professionals in product development, materials science, and new technologies convened for the 10th conference edition of RISE—Research, Innovation & Science for Engineered Fabrics, held virtually, Sept. 29-Oct. 1. The event was co-organized by INDA, the Association of the Nonwoven Fabrics Industry, and The Nonwovens Institute, and North Carolina State University.

Among the program highlights was the presentation of the RISE Innovation Award, which was presented to The Nonwovens Institute at North Carolina State University for its Spunbond High-Efficiency Filter Media. The product is a completely new approach to creating filtration media with the right efficiency at low pressure drop at a throughput of 350 kg per meter per hour. The pressure drop with The Nonwovens Institute’s new filter is unmatched by any meltblown structure and doesn’t require electrostatic charging, which has been an obstacle to facemask manufacturing during the COVID-19 pandemic. The materials is also much stronger than traditional meltblown filter media, thus providing the potential for reuse after appropriate cleaning and disinfection.

NWI said it has produced 4.5 million meters of the material so far, enough to produce 100 million masks.

Other nominees for the award included FemTech at MAS Holdings Pvt. Ltd. for its leakproof absorbent nursing pads and Sustainable Solutions Incorporated for its BlueCON Nonwovens initiative that produces recycled resin from hospital waste.

Source: riseconf.net

Freudenberg facemask technology certified Type II EN 14683

Freudenberg Filtration Technologies’ facemask technology is now certified as a TYPE II for medical applications (EN 14683). It combines effective health protection with first-class wearing comfort. Currently, the TYPE II masks are being sold exclusively to companies with a minimum order quantity of 7,500 pieces. Freudenberg Home and Cleaning Solutions GmbH will continue to sell the certified medical facemasks to consumers and companies under the Collectex brand.

At the heart of the mask is a three-layer polypropylene filter medium that is characterized by its superior breathability.

To learn more and request offers, visit https://lnkd.in/ejPmu6e.

Source: freudenberg-filter.com