Established in 1958, Harmsco Filtration Products, a third-generation family owned business, manufactures innovative and cost-effective solutions for liquid filtration challenges. Harmsco provides proven value-added products for three divisions: Harmsco Industrial Products, Harmsco Swimming Pool Products and Harmsco Municipal Products. As a pioneer in the filtration industry, Harmsco holds numerous U.S. and international patents for innovative filtration technologies committed to quality and value for the end user.

Innovations

Harmsco offers the world’s largest variety of NSF/ANSI Standard 61 listed filter cartridges and stainless steel housings available. This is accomplished

by continuous research and development of new technologies, materials and information.

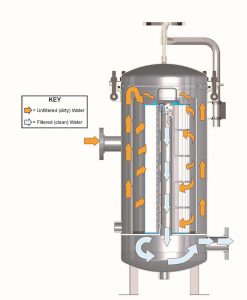

The Harmsco Hurricane filter housings feature a compact design with small footprint utilizing a combination of cyclonic separation with up flow cartridge filtration. With models handling up to 2,400 gpm (151.2 L/s) per housing, the Hurricane design can save up to 20p in energy costs due to the efficient design and flow path of the liquid you are pumping.

Harmsco Municipal Division offers EPA LT2 Certified filtration for municipal applications with 3.6 Log cyst reduction and up to 1,600 gpm per housing. Harmsco has proven installations throughout the United States, Canada and Worldwide.

The Hurricane cartridge filter’s intelligent design reduces feed pump electric costs up to 20%. Fluid enters the housing inlet tangentially creating a smooth centrifugal flow where cyclonic prefiltration removes & purges heavy solids prior to reaching cleanable and reusable cartridge(s).

See how we consume less pump energy with low pressure losses; provide longer filter runs and more: harmsco.com/z/100

This content is sponsored by Harmsco Filtration Products.