Bally Ribbon Mills (BRM), an industry leader in the design, development, and manufacture of highly specialized engineered woven fabrics, offers specialty fabrics constructed of specialty polymer fibers that help achieve filtration application manufacturing challenges, including reducing environmental impacts of manufacturing and energy production. Specialty fabric polymer selection is determined by the type of gas or air being filtered. Fabrics used are composed of either polyester or polyphenylene sulfide (PPS) for applications in which greater heat and acid resistance is required.

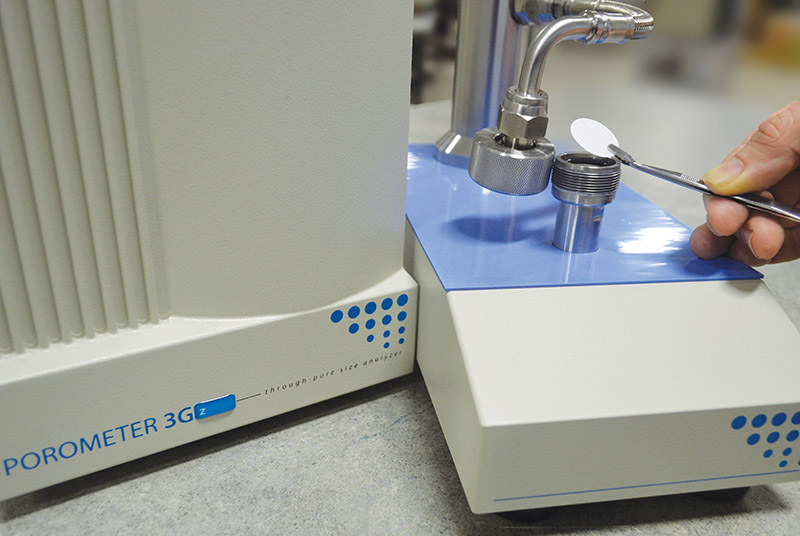

BRM’s specialty fabrics, available in a wide variety of fiber combinations and weave structures, are used in filtration applications requiring controlled air permeability and water porosity, as well as high seam strength and structural reinforcements for industrial air filtration applications. Seamless woven tubular fabrics can be created with a completely uniform fabric structure, often used in medical applications for liquid filtration.