Hydrophobicity occurs on the leaves of many plants in nature and is often referred to as “The Lotus Effect,” carrying out a self-cleaning function by preventing the penetration of water droplets so that they simply bead up and roll off it. As the water droplets roll off, they take any surface dirt and dust with them.

The hydrophobicity of a surface can be measured by its contact angle – surfaces with a contact angle of less than 90° are referred to as hydrophilic and those with an angle above 90° as hydrophobic.

Over the past 20 years, this natural phenomenon has been replicated in textile coatings to perform the useful task of keeping water out of apparel.

A new hydrophobic nanocoating, however, could have an even more important role to play in 2021 and going forward.

Capture Coating from Curran Biotech, based in Houston, Texas, can separate the SARS-CoV-2 virus responsible for the world’s current pandemic from the aqueous liquid-phase environment that surrounds it, and which it needs to remain in the atmosphere.

HVAC

Developed by a team headed by Professor of Physics at Houston University, Seamus Curran, and now being commercialized, Capture Coating can effectively and cheaply stop the spread and lingering impacts of the COVID-19 virus when applied to the filter fabrics in common HVAC (heating, ventilation, and air conditioning) systems.

While global vaccinations are likely to eventually subdue the current pandemic, COVID-19 – as a coronavirus-like influenza – is unlikely to disappear and will in the future need to be contained and managed with vaccines, much like the common flu continues to be.

Secret weapon

Capture Coating, however, could prove to be an essential new secret weapon in this management – potentially as important as new vaccines – by cheaply wiping it from indoor areas.

Speaking at the recent online 1st World Congress on Textile Coating (WCTC) – his presentation unfortunately delayed for a week by the North American winter storm that resulted in power outages across Texas – Professor Curran said the aim of Capture Coating was simply to clean the air of virus.

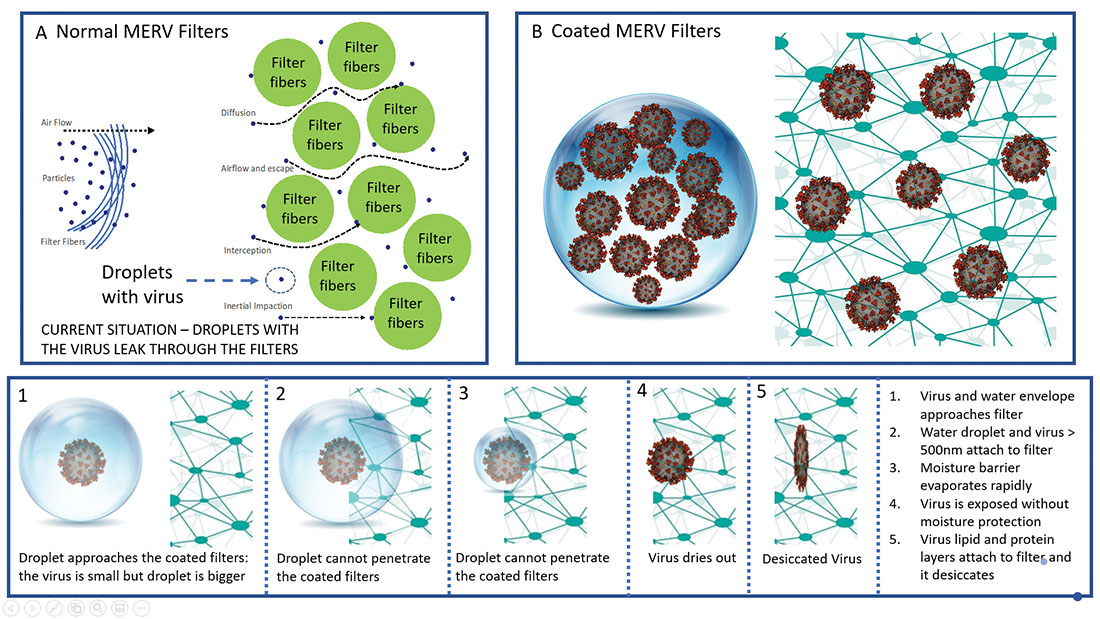

“We’ve been doing this for pollen and dust for many years, but unfortunately viruses are smaller than the weaves in most common filter systems and it’s only when you get to HEPA grades that they actually might start to work,” he said. “We started to look at the travel mechanism for the virus because viral transmission had been overlooked for many years, with the current social distancing advice largely based on studies of tuberculosis transmission in the 1930s.

“Over the past year, we’ve discovered that being six feet apart indoors is not enough to stop transmission. The virus can travel much farther indoors where there is no air current passing through. Due to Brownian motion the virus is also unaffected by gravity. As such, virus particles can remain in the air, only becoming ineffective when they eventually dry out.”

Liquid repellence

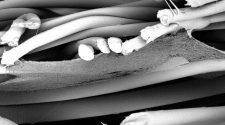

Rather than just using a form of detergent to kill the virus in real time – with no real long-lasting benefits – Curran Biotech took a different route. Its nanoscale coating wraps itself around the individual fibers of HVAC air filtration media, rendering them superhydrophobic without affecting critical HVAC operational parameters, notably airflow and breathability.

As a new superhydrophobic treatment, Capture Coating creates a liquid repelling, low surface energy surface that resists moisture or water-based liquids – not vapors – from being transferred.

“As such, hydrophobic coatings act as liquid barriers for water filtration and management and also as a penetrating sealer to prevent fouling by mold, mildew, bacteria and virus,” Professor Curran explained. “They have a low surface tension and are attractive to the outer layer of a virus, which is highly significant because the coronavirus in its most infectious state is surrounded by this aqueous liquid-phase environment.

“Once separated from this environment and captured in the filter, the virus simply desiccates. Capture Coating physically stops the travel mechanism of the virus at the surface of the air filter.”

MERV ratings

Capture Coating’s further advantages become apparent when considering the MERV (Minimum Efficiency Reporting Value) ratings of filter media and what they can handle.

Typical standard air filters for public buildings are MERV 6-8 grades, but as a response to COVID-19, public buildings – even restaurants and bars – have been advised to upgrade their HVAC systems to MERV 13 or higher filters.

Not only does this require a complete replacement of the actual filter system, but it bumps up the price of the individual filter media from around $6-8 to approaching $40 each, which is clearly a lot of investment to have to claw back for already very hard-hit small businesses.

With Capture Coating, MERV 6-8 filters can outperform much higher-rated filters in terms of viral protection, without impacting airflow, and there is no need to move to expensive new HVAC systems that are required to accommodate HEPA-grade filters.

Pollen to COVID

Interviewed after his WCTC lecture, Professor Curran spoke of the situation in New York last summer when Governor Cuomo said all bars and restaurants need to switch to a MERV 13 or 14 to guarantee any kind of safety.

“There was a huge eruption from the owners of these businesses because to do that switch meant they would have to change all their capital equipment – plus the cost per filter went up by a factor of six,” he said. “But now here in the USA at least, there’s a six-week lead on trying to buy a MERV 13 or 14 filter anyway.”

Asked why the price difference of the filters is so high, he said that the higher the MERV rating, the more fabric was required and the tighter the weave, which is how it is justified.

“If you look at a filter fabric, it is incredibly transparent and it is designed to be so, because you want the air passage to go through reasonably easily and just stop particulates. The whole idea to start with was to stop pollen and dander.

“Here in the USA, we have a lot of issues with pollen in certain places. If you go into Georgia or here in Houston, there’s so much pollen in the air and on heavy pollen days you can literally see it on your car like a coating. That is where filters came from in the beginning and fabrics were found to be great at stopping them, but they were never designed for viruses, that was not their purpose.

“We are using the already in-place filters in buildings as the vehicle for our nanocoating – which makes them effective against the virus – because everything else is already in place.”

Capture Coating is already being rapidly rushed out to distributors and retailers worldwide and is already now in use in many states within the United States.