Before 2018, the EN779:2012 standard allowed a wider range of particles sizes to pass. But on June 30th, 2018, a new global standard to classify air filters was established – ISO 16890-1:2016. ISO 16890-1:2016 is a standardized test and filtration efficiency classification system to categorize air ventilation based on particulate matter (PM). The testing ranks the efficiency of three particles sizes:

- 0.3-1mm (PM1)

- 0.3-2.5mm (PM2.5)

- 0.3-10mm (PM10)

This new standard adopted the particle range of PM1, PM2.5 and PM10, which aligns with the World Health Organization’s research on particle size as it relates to human health. Other test methods evaluate higher efficiency grades.

In addition to the change in particle size, the new standard also changed how materials are tested. With the EN779:2012 standard, the flat sheet filter media is soaked in an IPA bath for 2 hours and dried before being tested. The new ISO 16890-1:2016 standard tests the completed filter rather than the media on its own. The completed filter is placed in an IPA vapor cabinet for 24 hours and then tested. In both standards, the efficiency is tested before and after IPA exposure. These two numbers are combined as an average, which is how the media is placed in the filter classes.

One of the most common filter media is electret nonwoven media, which relies on a static effect. The IPA can degrade the static effect which lowers the efficiency in the post IPA test. This results in the media’s average score being reduced, which places it in a lower filter class even if the initial efficiency is high.

ISO ePM1 Efficiency Classification – Electret Nonwoven Media Test Results*

| Initial | Post IPA | Test Average | Minimum | Class Range | Class | |

| Media 1 | 96% | 17% | 56% | 15% | >50% | N/A** |

| Media 2 | 73% | 15% | 42% | 14% | >50% | N/A** |

**Reporting value of N/A shows the minimum efficiency is below 50% for ePM1 value.

In the example shown above, both medias show a large drop in performance. It’s important for filter manufacturers to evaluate the full performance of a media during these tests to understand the performance change, not just initial number and the average number of both tests. Reviewing both test results provides an indication of how the media performs over time.

One-way manufacturers can assure filter performance over time, is to choose a media that does not have a large efficiency drop between ISO 16890-1:2016 tests. One type of media that maintains performance on both tests is the PTFE filter media TEMISHTM.

The efficiency results between tests for TEMISHTM have a close range, illustrating that TEMISHTM maintains its performance over time. Keeping stable efficiency helps increase the longevity of the filter.

ISO ePM1 Efficiency Classification – TEMISHTM Test Results*

| Initial | Post IPA | Test Average | Minimum | Class Range | Class | |

| Temish NTF9307-L03 | 100.0% | 100.0% | 100% | 100% | >50% | ePM1 100% |

| Temish 2 NTF9304-L03 | 96.4% | 96.1% | 96% | 95% | >50% | ePM1 95% |

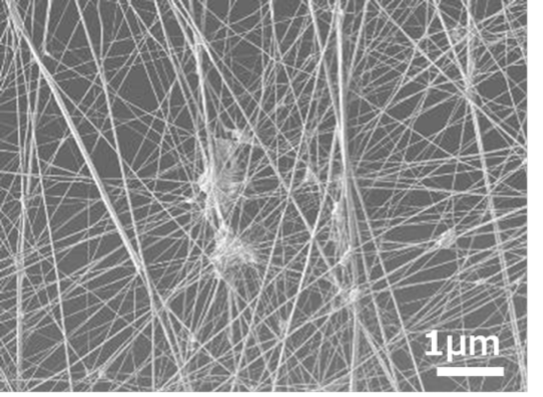

TEMISHTM is able to maintain this efficiency because it a relies on a mechanical filtration system that does not need to be charged. Other nonwovens are made of PET, PE or PP and are usually electrically charged to collect particles primary through electric attraction. This electric feature can wear down over time, reducing performance.

TEMISHTM is made with an PTFE that collects particles using mechanical filtration mechanism that allow it to achieve high collection efficiency during both tests. The collection efficiency is possible because of a thin fiber design. Fine fibers reduce pressure resistance (pressure drop) and increase collection efficiency resulting in a good balance between these two requirements. Because these mechanisms are built into its physical structure, it does not change or degrade over time.

Evaluating how a media preforms during both ISO 16890-1:2016 tests (rather than just the average efficiency), helps provide a better idea of how a media will perform over time. Further evaluating the makeup of a media, can also provide clues on the longevity of collection efficiency. TEMISHTM PTFE filter media shows consistent performance between tests indicating that it will help increase filter performance over time. And it’s fine fiber design allows it to achieve a good balance between collection efficiency and pressure drop.

This content is sponsored by Nitto.