Founded in 1934, ELSNER has been designing and manufacturing an innovative line-up of automation machinery to convert papers, films, foils, plastics and nonwovens for a wide range of industries for over 85 years. With over 3000 machines in over 60 countries, ELSNER is U.S.-based, offering sales and service support of our equipment in the U.S., Europe, and Asia. Our focus is on initiatives that have a direct impact on optimizing our customers’ operations to save time, labor and money. We believe that good business partnerships forge great outcomes; we’re not here to just sell the next new machine. We’re here to leverage our expertise and experience to develop solutions that help our customers reach the next level. Integrity, innovation in tailoring machines to customers, uncommon craftsmanship and incomparable value and service are our heritage, passion and promise to each customer.

Innovations

Having over 20 years of experience manufacturing machinery that automates the process of manufacturing spiral wound filters, ELSNER has launched ELSNER Filtration. Our line of automated filtration machinery removes manual processes and helps our customers manufacture a superior product. Our filtration solutions:

- Save labor costs

- Enhance quality control: make the manufacturing process of spiral membrane elements more consistent with a higher level of quality control.

- Improve the “active area” of the membrane with precision glue bead placement, lessening the chance for human error

- Boost productivity and the bottom line

- Provide U.S.-based support

We work with a variety of applications including desalination, food, beverage, dairy, biotech and pharmaceutical industries. Our solutions for manufacturing spiral wound filters are applicable to reverse-osmosis, microfiltration, ultrafiltration, nanofiltration and other processing needs. From filter assembly to trimming the element, our automated machinery helps ensure consistent quality, every time. The processes ELSNER Filtration machines can automate include folding, rolling, gluing, trimming and pack building.

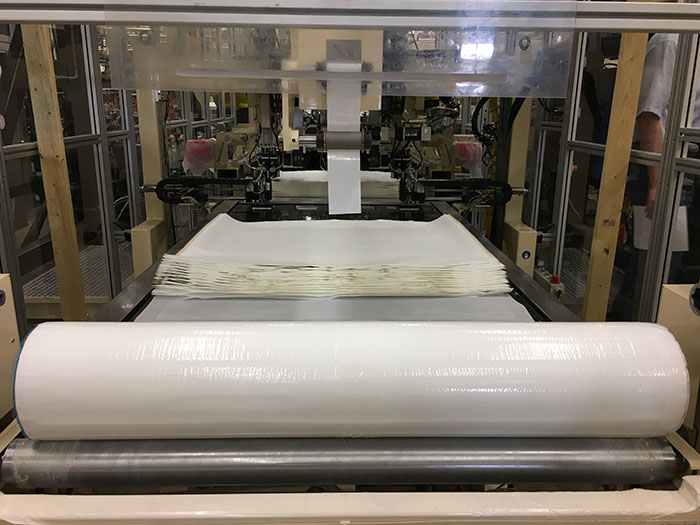

Automatic membrane folding:

The EMF-42 automatically converts membrane and plastic mesh into folded “leaves” for spiral wound elements.

Filter assembly and rolling:

The APB-42 provides automatic pack building. The machine is designed to bring together filter components to produce spiral wound filter elements.

Filter element finishing:

The Element Trim Saw is designed to finish the edges of industrial liquid filtration elements such as those made on the ELSNER EMF-42/APB-42 Element Production Line.

This content is sponsored by Elsner Filtration.