A2Z Filtration Specialties is a designer and manufacturer of filter production lines, filter testing equipment and filter components with a client base in over 70 countries across six continents. The company produces complete customer-centric solutions in the field of filter manufacturing and excels in providing superior value, durable and globally serviceable product lines. Machinery components are sourced from leading global suppliers to ensure an ease of availability and trouble-free maintenance. Features such as remote access for servicing and upgrading equipment software are coupled with pictorial manuals to make these products easy to use, efficient and excellent value.

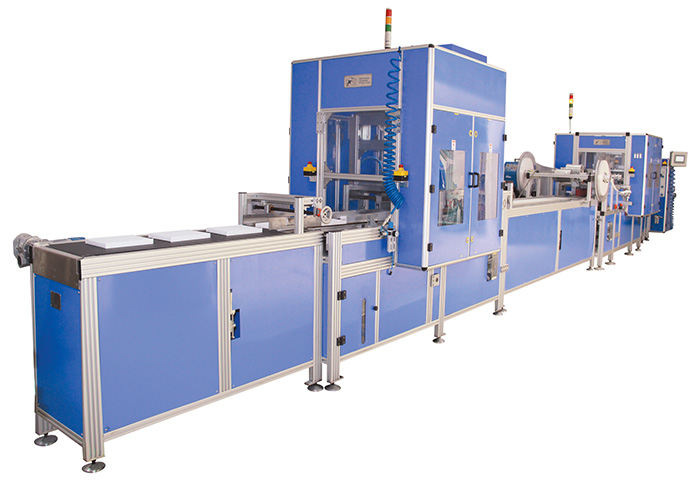

In its 18 years of business, A2Z has sold over 1500 machines covering a wide range of filter manufacturing processes. A2Z can offer unique, fit-to-purpose solutions to produce filters with newly developed technologies and increasing performance. Built-to-purpose lines can be designed to meet the new process requirement, validate quality, improve productivity and reduce human contact. A2Z covers the complete range from assembly cells to mini pleat lines from blade pleaters to ultrasonic seam seal equipment. This solidifies the company’s position as a complete solution provider to the filtration industry. A2Z services some of the world’s leading filter manufacturers.

Case study

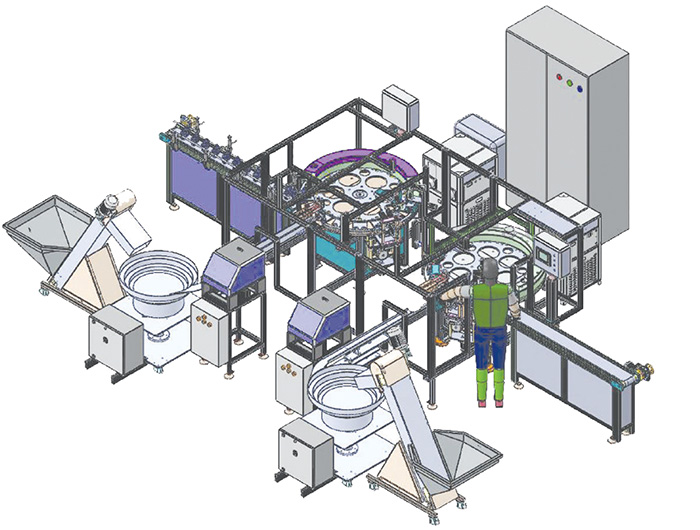

The Filter Assembly Cell, as highlighted in the 3 dimensional sketch, shows an example of A2Z’s built-to-purpose Automatic Assembly Cell, which is used to manufacture medical filters. In this case, the customer came to A2Z with a mandate to produce the filter with minimum human contact, as well as throughput of 40 filters per minute. The product was required to be processed in a controlled environment since the product was used in a medical application and the media could not be exposed to any contaminants.

A2Z Filtration’s team worked with the customer to develop an acceptable concept. This involved study of the customer processes, input specifications, capacity, changeover requirements and automation needs.

A2Z Filtration’s design team worked closely with the customer and other stake holders to build a complete production line. From the start of the project until the installation at the customer’s end and the validation trials, the project took six months to complete. During this time, there were certain design changes, as well as the addition of processes to meet the sensitive nature of the product.

A2Z engineered an acceptable solution and provided a fit-to-purpose fully automated production line.

A2Z Filtration offers:

- Customized Manufacturing & Assembly solutions.

- Value Prices for Quick R.O.I.

- Ability to integrate your existing equipment to various Automation Solutions, new Processes & Online Quality Validation Systems.

- Globally Serviceable Production Line.

- Latest State Of The Art Manufacturing Solutions.

This content is sponsored by A2Z Filtration.