Hard seltzer is a rising sensation within the realm of alcoholic beverages. This drink made its mainstream market debut only a few years ago and is experiencing an escalating trend in numerous nations.

Across the world, hard seltzer is seizing markets with remarkable force and boasted an approximate global worth of $15.8 billion (14.6 billion euros) in 2022. Of this substantial sum, around $13.6 billion (12.6 billion euros) can be attributed to U.S. demand alone. Future projections indicate a robust annual surge of over 30%, propelling worldwide sales to about $36.8 billion (34 billion euros) by 2025.1 Meanwhile, in Germany, where the sector remains relatively modest at roughly $54.2 million (50 million euros) in 2022, a staggering 88% annual growth rate is anticipated in coming years that could propel the market’s magnitude beyond $347.2 million (320 million euros) by 2025.2

Hard seltzers are commonly perceived as a pristine product devoid of odor and displaying a transparent appearance. This quality holds significant market potential, contingent on the implementation of appropriate filtration technology to enable its realization. With the entry of many long-established alcoholic drink manufacturers into the market, the process of production introduces a novel learning curve. The difficulty lies in the potential for the raw materials (depending on quality), as well as the processes of fermentation and flavoring, to induce haziness, introduce coloration, or even modify the taste of the liquid.

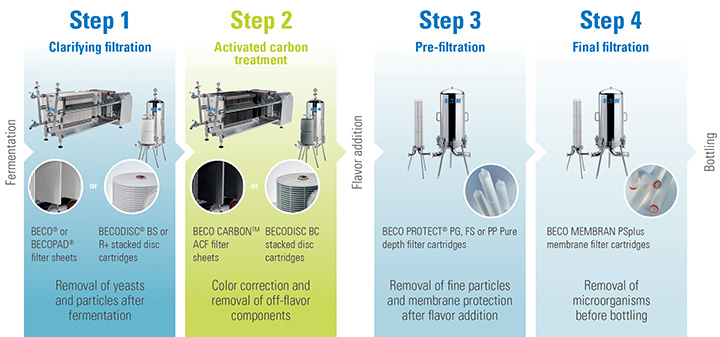

Thus, a multistage filtration procedure assumes a crucial function by facilitating clarification, eliminating unwanted color, and tuning out off-flavors to yield a final product that is both palatably pure and visually clear. The clarification phase effectively eliminates yeast, haziness, and other potential particles. Color and aroma refinement is meanwhile accomplished using filter media infused with activated carbon. Prior to bottling, a final filtration process helps to ensure the clarity and longevity of the beverage. Such techniques allow producers to achieve optimal safety, quality and consistency, empowering them to craft a hard seltzer that’s not only crystal clear but also exceptionally delightful.

Activated carbon-embedded filter media offers a high adsorption capacity for decolorizing and aroma correcting; improves process hygiene; allows easy, virtually dust-free handling; and facilitates short setup times.

Filtration: Unlocking Optimal Outcomes

While the straightforward ascent of these alcoholic beverages can be readily understood, the process of perfecting them remains complex. Hard seltzers can be crafted using various approaches that combine carbonated water with a wide spectrum of raw materials. Among the initial commercially available hard seltzers, some were crafted from lemons or underwent fermentation from malt. In contrast, the prevailing practice in North America involves employing mineral water as a foundation, infused with a small proportion of high-proof alcohol distilled from cane sugar.3

Even well-established manufacturers must meticulously examine the intricacies of producing a beverage that aligns with consumer anticipations. One factor contributing to this challenge is the pursuit of absolute clarity.

Clarifying Filtration

For hard seltzer, the initial fermented liquid requires meticulous filtration using plate and frame filters (the standard in basic process depth filtration) or stacked disc cartridge housings. The former consists of a series of alternating plates and frames arranged in a stack. The plates are equipped with depth filter sheets that capture suspended microorganisms and particles while allowing the clarified liquid to pass through.

Stacked disc cartridges meanwhile are cylindrical filter units consisting of multiple stacked filter cells. This filtration solution tends to be more compact in design, allowing for efficient installation where space is limited. Additionally, a significant benefit is that it operates as a closed system, meaning the fluid being filtered remains completely enclosed within the cartridge. This also reduces the need for constant monitoring and maintenance, as it is less prone to external contamination.

Both methods are suitable for clarifying filtration because they help achieve a clear and visually appealing liquid while removing unwanted particles. The choice between depth filter sheets and stacked disc cartridges would depend on factors such as the desired level of filtration, the type of particles to be removed, the volume of liquid to be processed, and the available equipment and space.

Activated Carbon Treatment

Following the clarifying filtration, an additional step involving activated carbon filter media is crucial for creating the transparent and initially neutral-tasting foundation needed for hard seltzer. This is primarily because activated carbon filtration is remarkably adept at removing color through the process of adsorption.

Activated carbon finds applications in the pharmaceutical, biotechnological, fine chemical processing, as well as the food and beverage industries. Its utility lies in decolorization, eliminating undesired by-products, enhancing taste, eliminating odors, and correcting colors. Frequently, it is manually added to the processes in powdered form, often referred to as PAC (Powdered Activated Carbon).

Immobilized activated carbon on the other hand offers certain benefits over loose PAC, including reduced dust exposure and enhanced downstream processing. Additionally, the scale-up process is made more straightforward thanks to the predictable filtration capacity. As the activated carbon content is meticulously specified and bound within the filter material, it helps to ensure both high and consistent product quality, along with reliable filtration performance in various applications.

In this phase, both depth filter sheets and stacked disc cartridges containing activated carbon can be employed for safe and efficient purification.

Pre- and Final Filtration

In the final steps, depth filter cartridges and membrane filter cartridges are employed to maintain microbiological stability by effectively separating fine particles and microorganisms prior to beverages being carbonated and bottled.

Depth filter cartridges come in two primary variations: pleated and wrapped. Typically constructed using polypropylene as the chosen filter material, these cartridges serve a pivotal role in pre-filtration processes, acting as the vanguard against potential contaminants that could compromise downstream membrane filter cartridges.

Wrapped depth filter cartridges exhibit a unique design characteristic where the individual filter layers progressively refine from the outermost layer to the innermost. Their innovative structure also offers the advantage of being back washable, ensuring a longer life span and making them mechanically robust for rigorous applications.

For applications requiring precise filtration, depth filter cartridges with stringent retention ratings are indispensable. These cartridges excel at removing fine particles and shielding membrane filter cartridges from clogging substances present within the fleece matrix, employing a highly effective sieve effect to maintain the integrity of downstream filtration processes.

Membrane filter cartridges are another critical link in safeguarding the purity and efficiency of the final bottled product. These serve a crucial role as the “policing filter” in maintaining the microbiological stability of beverages during the filtration process prior to bottling. Their significance lies in their unique ability to undergo integrity testing, which guarantees the operational efficiency and integrity of the membrane filter. This integral quality control measure helps to ensure the consistent delivery of high-quality products to consumers.

Within the realm of alcoholic beverage production, membrane filter cartridges can help to attain a superior level of filtration, surpassing the capabilities of depth filters by effectively eliminating minute particles and bacteria. This meticulous filtration process proves indispensable, as even the tiniest microorganisms have the potential to cause spoilage, introduce off-flavors, or trigger unwanted fermentation within the final bottled product.

A Hard Look at Seltzer

The investigation into optimal filtration methods for achieving superior outcomes in the context of hard seltzer remains in the early stages, primarily due to its recent emergence. Addressing this gap, Dominik Eckert, a student at Hochschule Geisenheim University in Germany, dedicated his efforts to comprehensively explore the transformation of unfiltered base wine into hard seltzer as part of his undergraduate thesis.4

Eckert’s research placed special emphasis on the assessment of the decolorization capabilities of activated carbon filter sheets. The experimental protocol encompassed multiple phases and was repeated on four separate occasions using a dedicated filtration test bench. In the initial stage, the focus was on assessing the filterability of the base wine and subsequently enhancing it through clarifying filtration techniques. Subsequent phases delved into diminishing the color intensity of the pre-clarified base wine. This was achieved by utilizing activated carbon filter sheets at varying flux rates (flow rates). Final phases were centered around evaluating the potential impact of the introduction of grapefruit flavor on both the coloration and filterability of the resulting beverage.

As anticipated, the use of activated carbon filter sheets emerged as a highly recommended filtration method that contributes to the desired visual and sensory attributes. Notably, the tests revealed enhancements in particle separation, yielding positive outcomes for overall filtration performance and subsequent achievement of desired color intensities. Moreover, as a consequence of introducing flavor, all filtration parameters remained unaltered.

In this extensive series of tests, the utilization of activated carbon filter sheets emerged as a standout choice for effective filtration. The filter sheets effortlessly delivered the desired optical and sensory attributes, making them a highly recommended option. Furthermore, the tests unveiled a noteworthy enhancement in particle separation, leading to a notable improvement in the overall filtration efficiency.

The findings derived from Dominik Eckert’s bachelor’s thesis, conducted in collaboration with experts from Eaton Filtration Division, offer manufacturers valuable guidance on optimizing their processes for the production of hard seltzers. Regardless of the ever-changing characteristics of fermented raw materials, these recommendations enable companies to attain peak levels of process reliability and product quality.

The result? Hard seltzers that not only meet the highest standards of safety but also boast an enticing visual appeal and a delicious taste that consumers crave.

Making Hard Seltzers Easier

Hard seltzer remains a relatively new offering, and many operators lack significant experience in its manufacturing. However, since visual and sensory attributes play a pivotal role in meeting consumers’ expectations and desires for this beverage, specialized process knowledge and substantial filtration expertise are imperative.

Among millennials and Gen Z consumers especially, this light alcoholic beverage resonates as a lifestyle choice. Manufacturers can address the challenge of producing a preferred hard seltzer through meticulous filtration steps and premium filtration media, helping their products sparkle in a market thirsty for refreshment.

References:

- Statista (2022): Hard seltzer worldwide, online: https://de.statista.com/outlook/cmo/alkoholische-getraenke/hard-seltzer/weltweit (accessed on 12/21/2022)

- Statista, (2022): Hard seltzer Germany, online: https://de.statista.com/outlook/cmo/alkoholische-getraenke/hard-seltzer/deutschland (accessed on 12/21/2022)

- Wikipedia (2022): Hard seltzer, online: https://de.wikipedia.org/wiki/Hard_Seltzer (accessed on 12/18/2022)

- Eckert, Dominik (2022): Filterability of hard seltzer drinks, Hochschule Geisenheim University, bachelor’s thesis, 05/30/2022

![Figure 1: Heat Exchanger Proventics GMBH.[22]](https://www.filtnews.com/wp-content/uploads/IFN_2_2024_crimpedmicrofiberyarns_Fig.-1-Heat-exchanger-225x125.jpg)