Filtration Professionals From Far and Wide Come Together at Chicago’s Navy Pier to Discuss the Industry’s Future, Technology & Innovation

The much-anticipated FiltXPO 23, held October 10-12, 2023, in Chicago, IL by INDA – the Association of the Nonwoven Fabrics Industry, was a huge success according to exhibitors and attendees. Many exhibitors noted that the attendee base was an impressive array of C-suite leaders, decision makers and innovators who spent quality time discussing industry needs with them. Attendees enjoyed the two-day training from INDA, as well as a technical conference that included an impressive line-up of thought leaders, who provided a deep dive into varying solutions for current filtration challenges.

FiltXPO is known as North America’s leading exhibition and technical conference dedicated exclusively to filtration and separation products and processes. Here are some key highlights and photos of the event.

Filter Media Course

The two-day Filter Media Course, conducted by Behnam Pourdeyhimi, Ph.D., Professor and Executive Director, The Nonwovens Institute; Hechmi Hamouda, Ph.D., Professor Textile Engineering, NC State University (ret.); and Hooman Tafreshi, Ph.D., Associate Professor Mechanical and Aerospace Engineering, NC State University, allowed participants to develop an overall understanding of nonwovens and their applications in air, liquid, and aerosol filtration, technologies, unmet needs, and trends for future development.

Technical Conference

The technical conference highlighted key topics affecting the filtration industry today and for the future and was co-organized by the Waterloo Filtration Institute. The conference featured sessions on filter media technologies, advancements and opportunities in filtration machinery and equipment, innovations in clean air for homes and urban areas, standards and testing, industry trends and new developments, and filtration challenges and opportunities.

Keynote Speaker Fred Lybrand, Global Marketing Director for Process Liquids, Hollingsworth & Vose (H&V), spoke on “Accelerating Membrane Adoption with ROI,” highlighting four niche projects that H&V worked hands-on to develop custom solutions to their clients’ needs in food preparation, wineries, breweries and bio processing sites. He emphasized that establishing a solid return on investment is critical to adopting technology because of the time investment companies must make to bring new solutions into their systems.

“It is important to really know the goals of your customer for them to invest in a new product and be able to estimate the potential return on that investment,” he said. He led attendees through the four projects and how his team problem-solved each situation for a positive outcome for the client. “Higher yields, higher product quality, higher revenue and/or higher margins at the same cost for element is the goal.”

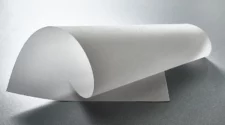

Looking to the future, H&V is meeting their market demand with Trupor® Filter Media. Trupor® leverages two centuries of H&V innovation in fibrous porous materials. It is the company’s first product for buyers of microfiltration membranes, targeting food, beverage, and bioprocessing applications.

Koen Bastiaens, Global Industry Manager – Emerging Markets, NatureWorks LLC, another lead-off speaker, held an interesting session on “Optimizing Biopolymers to Improve Filter Performance,” which discussed emerging market trends in using biomaterials to provide more sustainable material choices, and also to improve filter performance – a topic top of mind to many in the room. He emphasized this is critical to sustainability for the industry. “I would argue that we can’t recycle our way into sustainability, with one trillion pounds of plastics produced from oil and gas in just 2022 alone,” he notes, and it is growing by 25 million pounds each year.

“We must work towards higher performance MERV ratings and find ways to get there. Raw materials need to be considered in the full cycle of product development, not just reuse and recycling,” pointing to NatureWorks Ingeo™ PLA, that provides multiple after-use pathways, including Ingeo 6500D solution with topical treatment improves fluid management, durability and breathability. NatureWorks developments targeting filtration, specifically, include Spunbond, Meltblown, SMS; Electrostatic Charge Retention; Fiber Size, Distribution; Bicomponent; PLA, PP, acrylate; Blended materials; wool; and Electrospinning.

Standards and testing was a strong topic of discussion in light of current events. Jon Rajala, Ph.D., R&D Manager, AAF International, presented “Air Filter Standards Activity and What It Means for Innovation.” His talk started with a history of air filtration standards, and ended asking pointed questions and concerns. “Better standards, better test methods, then we get better filters,” he notes. “ASHRAE 52.2 is not a widely used standard and it needs to be become mandatory. If ASHRAE 52.2 doesn’t respond, it will be irrelevant, and consumers will find other options, if we can’t answer the standards questions.” He concluded, “The full 52.2 method does not address minimum possible efficiency. Appendix J is not mandatory, and frankly, not widely used. If Standard 241 becomes widely adopted, Appendix J essentially becomes mandatory. Therefore, Standard 52.2 must address this issue before other standards mandate it.” He advocated for better awareness of health impacts from air pollution and PM2.5/PM1 exposure, which are linked health issues such as Alzheimer’s, heart disease, strokes, asthma and lung cancer. This kind of awareness will drive better innovation and standards that are achievable.

Gary McCurdy of Air Technologies International spoke on “Application of Automated Filter Tester in Quality Control Testing,” with a focus on the importance of consistent aerosol particle size distribution. He also championed the idea that there must be an overall tightening of the standards to achieve standards reliable results. “Standards are too varied; part of the problem is the standards are too wide,” he noted. “The regulations are too loose. If you have a goal of .70 +/- 20 microns, that gives you a range from 90 to 50 that is acceptable. That is way too broad a range and wildly different results from one end of another.” He said that testing relies on the importance of consistent aerosol PSD in AFTQC (incoming material, processes, etc.), historical data, and R&D parameters. “We should have factory acceptance reports that include PSD data, and the industry should perform repeated testing of one sample.”

FiltXPO 2025 and the Filter Media Course will be co-located with IDEA®, taking place April 29-May 1, 2025, in Miami Beach, FL. More information will be available January 2024 on www.filtxpo.com.