Franz (Frank) Elsner, Sr. and his wife Johanna immigrated to America in 1924 to escape the depression and turmoil of post-World War I Germany. A German mechanical engineer, Frank held many jobs in his early years in his new country. He worked as a machinist, a patent drafter, a mechanical designer and a plant engineer in a cigar box factory.

The business started in a former broom factory with two employees and today occupies a 117,000 square foot state-of-the-art manufacturing facility with over 100 employees. Innovative design, customer satisfaction, and steady growth have always been the Elsner business plan. Started by Frank Elsner, Sr., that business plan continues to work today.

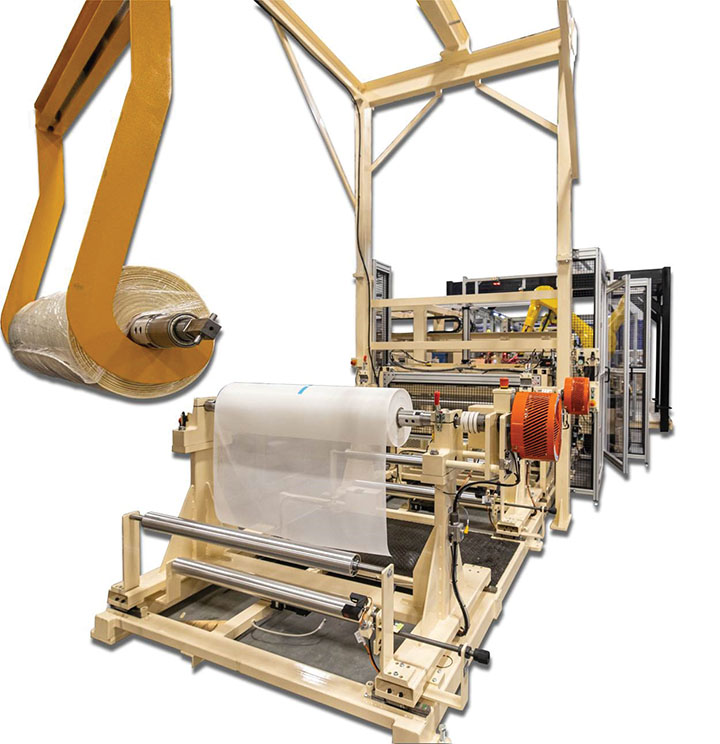

In 1954, Frank first saw the potential in redesigning the automatic rolling or rewinding machine. Frank thought the industry needed a machine that was more versatile, easier to set up, and did what the customer needed it to do.

The first Elsner rewinder and Elsner roll overwrapper were sold in December 1955 to Tuttle Press Company for their gift wrap line.

From this humble beginning, there are now more than 3,000 machines of various sizes and configurations operating in 60 countries worldwide today. The company entered the spiral-wound filtration market in the early 2000s, and it quickly achieved recognition in this space.

Here we speak with Jay Roth, director of sales for Elsner, as the subject of the “Executive Q&A” feature in this edition of IFN.

Jay Roth: It was about 20 years ago that a filtration company found Elsner on the internet and asked us to visit and discuss building a custom machine for them to cut and fold membrane to produce the “leaves” used in spiral wound RO elements. Our national sales manager at the time flew out to see them, took down the details and brought it back to our engineering team. We proposed a brand new machine design. Having built around 800 different machines in our history, we had a lot to draw from, but we had never built anything that was a direct fit.

IFN: The COVID-19 pandemic has brought challenges and new possibilities to the filtration industry. How has Elsner navigated the past two years?

Jay Roth: We have been fortunate to stay active throughout the pandemic. We build machines not only for filtration, but for wipes and medical disposables as well. We took the role of an essential supplier very seriously and were proud to have not only kept our doors open all this time but have grown substantially – 35% of our current staff were hired during COVID.

We see continued impact on our customers with maintaining a full and complete staff. This builds the case for automation. The more reliable and efficient we make our machinery, the less our customers/partners need to be reliant on staffing requirements.

We will continue to visit with filtration companies around the world to make sure we are keeping up with any changes in the industry and are taking a close look at the various processes and methods they use to determine how we can best help them.

IFN: Elsner has also played a role in manufacturing wipes to support the pandemic response. What can you tell us about that experience and Elsner’s capabilities in this regard?

Jay Roth: Elsner has been the leader in rolled wipes converting equipment for some time now. Just prior to the pandemic, we released our 3rd generation ENR-Series machine the ENR-G3. We were happy to support our customers in this industry by building a large number of machines to support the surge in wipes demand. We were taking orders at a much faster pace than we could build machines. To help supplement, we started running our own “lab” machine in our Tech Center to run production for our customers. We quickly moved to three shift operation with the Tech Center team and were not only able to help our customers, but we employed more people than we ever had before.

IFN: What can you tell us about Elsner’s automation capabilities and how its IIoT solution set has evolved in recent years?

Jay Roth: As mentioned previously, our automated solutions reduce the burden on our customers workforce. We see this as providing opportunity to use employee skills for better tasks than some of the manual operations they were performing before adding Elsner machines. With IIOT, we provide a platform for easy and immediate feedback on how our machines are running. Elsner customers can get real-time visibility on machine production, status and other runtime data.

IFN: From Elsner’s perspective, what do you see as the key areas of opportunity in filtration over the next 5-10 years?

Jay Roth: We plan to continue to push ourselves in making our machines more efficient and continuing to add to our automation options for element production. We already have concepts for other steps in the process beyond just folding and rolling. We will continue to visit with filtration companies around the world to make sure we are keeping up with any changes in the industry and are taking a close look at the various processes and methods they use to determine how we can best help them.

IFN: Is there anything about Elsner and/or your perspective on filtration applications or technology that we haven’t touched upon here that you feel is important for our readers to know?

Jay Roth: I think the same gameplan that has made Elsner successful for our first 85-plus years is what is going to keep us around for 85 more. We have a wide variety of experiences to build on. It may not seem like a rolled wipes, giftwrap or aluminum foil rewinder would have anything in common with a filtration production line, but there are actually a lot of similarities. Web handling and tension control are key to all converting operations. We cut, roll and fold a myriad of materials. We’ve built machines that ultrasonically weld, heat seal, fold, roll, stack, tape, label, crimp, glue, cut and more. We always have some starting point, even for the most complex operation. Our engineering team does an amazing job of breaking down processes into something we can automate.

![Figure 1: Heat Exchanger Proventics GMBH.[22]](https://www.filtnews.com/wp-content/uploads/IFN_2_2024_crimpedmicrofiberyarns_Fig.-1-Heat-exchanger-225x125.jpg)