The INDEX nonwovens exhibition, organized by EDANA (the European Disposables and Nonwovens Association), was first scheduled to take place in Geneva, Switzerland, in April 2020.

By then, however, the world had been changed beyond recognition – in just a couple of months – from what was known before.

The event was subsequently rescheduled a number of times, but the fact that it finally went ahead this October – triumphantly opened by INDA’s president Dave Rousse – led to an exhilarated mood amongst attendees, and also gave a slightly nostalgic flavor to an international meeting that had been held so regularly and seamlessly at the same location many times before. In some ways, it was like visiting a past life. Let’s hope it might be part of the future too.

The show attracted some 9,300 visitors over its four days and featured over 500 exhibitors on more than 48,500 square feet of exhibition space.

Hybrid format

“The visitor count is even more remarkable considering that over a thousand further professionals joined the on-line version of INDEX, as the show was presented for the first time ever in a hybrid format, allowing exhibitors to match live and virtual stands featuring their products and services,” said EDANA general manager Pierre Wiertz. “The virtual platform will stay accessible until November 15th to allow all on-site and virtual participants to watch the content from the sector seminars.”

The overall filtration industry, Sievert said, has an annual value of around $80 billion, and will grow at between 4-6% up until 2030, to reach an annual value of around $100 billion.

“Our business contacts at INDEX are usually all about long-term relationships and contracts, with additional new opportunities a plus,” added Mikael Staal Axelsen, CEO of Fibertex Nonwovens. “For this edition, it has been first and foremost a matter of once again meeting business partners face to face after so many videocalls, and the pleasant surprise is that overall, the result exceeded our expectations.”

Story of the century

Meltblown nonwoven fabrics were in many ways the filtration industry story of 2020, if not the century.

Never before has a filter media – as the essential layer in surgical-grade facemasks – become the focus of governments around the world, or so much unprecedented activity from multinational companies and anyone else who wanted to help.

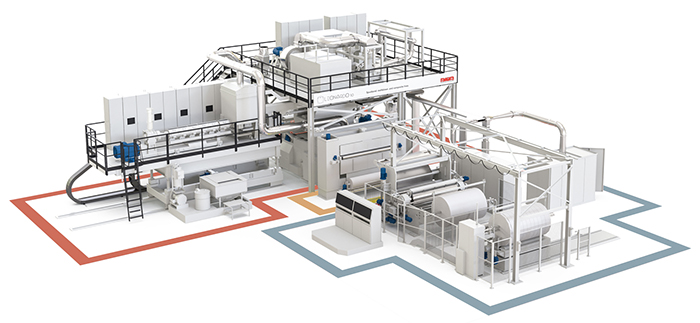

As a consequence, COVID-19 resulted in unprecedented success for some of the European machine builders with meltblown technologies at this year’s INDEX, such as Germany’s Reicofil and Oerlikon Nonwovens, and Ramina of Italy.

The big issue for machinery builders right now – and across many industries – is the global shortage of microprocessors, which is leading to difficulties in planning and scheduling the delivery times for new machines. Timelines have already been hampered by transportation difficulties in differing parts of the world during the pandemic and further compounded by subsequent significant increases in the cost of both shipping and energy.

Meltblown fabrics, in composites with spunbond materials, are also central to the manufacturers of absorbent hygiene products (AHPs), such as baby and adult diapers and femcare articles, which is the biggest sector for nonwovens and as such central to the INDEX show.

The AHPs industry boomed during COVID-19, not least initially due to panic buying both by consumers and retailers. AHP manufacturers are now looking for security of supply and to diversify their supply bases and at INDEX this appeared to be benefiting the key spunmelt nonwovens suppliers in Turkey such as Nonwovens, Hassan, General and Mogul, whose stands were always busy in Geneva.

$100 billion industry by 2030

In a dedicated afternoon seminar on filtration held alongside the INDEX show, Joerg Sievert, COO of Freudenberg Filtration Technologies, provided a comprehensive overview of the global filtration market before drilling down into the specific demand for nonwoven fabrics for air filtration, which of course, has been boosted by COVID-19, but is unlikely to recede, given the increasing importance of cleaner air for everyone.

The overall filtration industry, Sievert said, has an annual value of around $80 billion, and will grow at between 4-6% up until 2030, to reach an annual value of around $100 billion.

He split this overall market into five key categories, namely:

- Inertia separators, such as cyclones, classifiers, coalescers and baffle separators;

- Electrostatic precipitators;

- Solid-liquid separators such as hydro-cyclones, cross-flow filters, cake filters, cartridge filters and venturi scrubbers;

- Separation with filter media in pocket, cassette and cartridge filters, as well as baghouses;

- Odor and gas removal separators, such as granular bed filters;

Clean air

Specifically for air filtration, nonwoven filter media represent between 7-9% of nonwovens applications according to statistics from EDANA for Europe, so remain something of a niche market, but are employed in a wide variety of filter designs.

Among other speakers at the seminar, Patrick Demchko, global director of marketing and filtration for Hollingsworth & Vose, outlined the benefits of Nanowave, the company’s extended surface synthetic filter media.

Not only does Nanowave provide cleaner air, it can lower energy consumption in commercial, residential and industrial buildings because its patented wave design allows air to permeate with less resistance in smaller filters. Kari Luukonen also spoke of the expanding use of nanofibers in Fibertex filter media, including for FFP2/N95 facemasks.

COVID Capture

A second seminar, entitled Smart Nonwovens for High Performance Applications provided a few examples of potentially new areas for filter media.

The UK’s NIRI (the Nonwovens Innovation and Research Institute) has developed a new adsorbent technology for the selective filtration of atoms, compounds, molecules and particles from both gaseous and liquid environments.

These engineered nonwovens can be specifically tailored depending on the nature and volume of unwanted matter, the specific application, the carrier fluid and separation performance requirements.

Ross Ward, NIRI’s commercial director, provided details of two projects in which this technology is being applied.

In hospitals, increased environmental contamination with SARS-CoV- 2 can be found in places where PPE is removed and in the COVID-Capture project, NIRI researchers are looking at making improvements to PPE materials that could reduce the risk of dissemination of virus into the environment, and of transfer between staff and patients in the healthcare setting.

To date, the work has involved screening plates with affinity ligands attached to an agarose matrix to ascertain their ability to bind and retain SARS-CoV-2.

The best performing candidate ligands have been conjugated to PPE nonwovens and the affinity of ligand-PPE nonwoven prototypes has been assessed along with validation of SARS-CoV-2 immobilization.

The prototype Covid-Capture PPE is now being evaluated in clinical trials.

Sanguis

In the second project, Sanguis, researchers are working to create a universal plasma that can be safely transfused to all blood group types.

Incompatible blood type plasma transfusions can cause red blood cells to clump together, Ward explained, and red blood cell agglutination with mismatched plasma can cause blood clots and be fatal.

The Sanguis project is focused on the removal of blood group antigens from plasma by filtration. A novel gravity fed filter for removing ABO blood group specific antibodies from donated blood plasma has been developed. The antibodies are covalently bound to the antigen on the filter surface and antibody removal efficacy testing has already yielded impressive results

The key benefits will be in improving patient safety while allowing hospitals to keep a single stock of plasma on site.

The UK’s NHS (National Health Service), which has been involved in the project, estimates that it could save an annual £5 million a year through reducing emergency delivery costs, wastage, administration and logistics, as a result of the universal plasma filter system.

Fibroline

French company Fibroline has meanwhile developed and patented a range of dry powder impregnation technologies which have many potential applications in both air and water filtration.

The technology allows the precise distribution of a wide range of powders from 5 to more than 500 microns, either within or on the surface of filter fabrics. The powders can include thermoplastics, thermosets, superabsorbent polymers, medical additives, cosmetic powders, fire retardants, etc.

CEO Jérôme Ville explained that the environmentally friendly process has very low energy consumption and no solvents or water are employed. He provided details of successful commercial cases for the technology in the AHPs, medical and beauty industries, but said that new applications in the filtration industry were currently proving the most promising.

INDEX 2023

The next INDEX show will once again take place at Geneva Palexpo in Switzerland from April 18-23 2023.

![Figure 1: Heat Exchanger Proventics GMBH.[22]](https://www.filtnews.com/wp-content/uploads/IFN_2_2024_crimpedmicrofiberyarns_Fig.-1-Heat-exchanger-225x125.jpg)