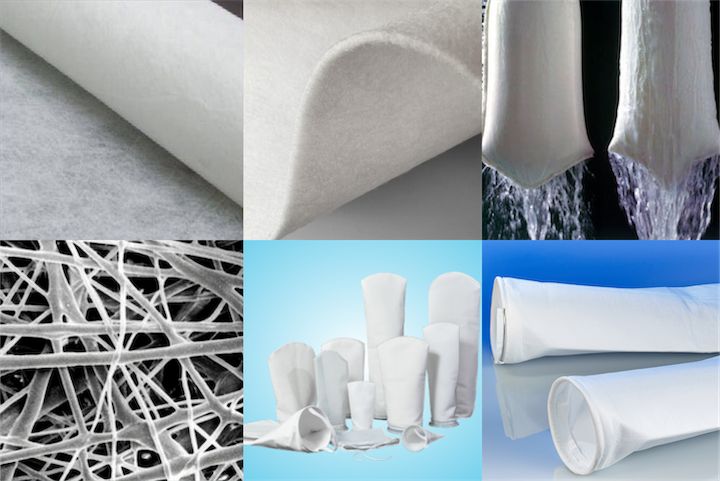

With the future of liquid filtration appearing to be bright, PARK Group has made key investments in the first quarter of 2021 to enable liquid filtration media production. While manufacturers and suppliers in the filtration industry push forward with innovations and capitalize on current growth areas and trends, PARK Nonwoven is targeting liquid filtration media as a new area of opportunity, with a focus on bringing high-quality mate¬rial innovation to life and building lasting customer relationships to drive growth and attain market leadership.

Among its latest new product offerings, PARK Nonwoven has dust bag filter media, a far-reaching material innovation for pharmaceuticals, cement, power plant, metal, chemical and other heavy industries.

PARK’s liquid filter media:

- PP / Polyester Filter Media – 1 microns, 5 microns, 10 microns, 25 microns, 50 microns to 100-200 microns for the press filter, bag filter & cartridge filter.

PARK’s dust bag filter media include:

- Polyester Filter Media [PET]

- PP Filter Media

- P84 Filter Media

- PPS Filter Media

- Glass Fiber Filter Media

- PTFE Filter Media

- Nomex Aramid Filter Media

- Homopolymer Acrylic Filter Media

- Copolymer Acrylic Filter Media

Manufacturing processes include felt production, needle punch, stitch bonding, thermo bonding, compression molding, meltblown and spunbond. We have 1000+ happy customers, and we are serving in 25+ industries. The Group also export into 75+ countries and have 10+ plants.

PARK Group has in-house globally recognized testing capabilities and take pride in our resources and infrastructure, carrying out stringent quality tests at our premises to roll out the best of nonwoven fabrics and polymer products.

Key capabilities include:

- In house testing lab for breathing resistance, tensile strength, elongation, GSM test, dust-holding capacity, particulate efficiency, pressure drop and pore size.

- Treatments we offer: PTFE Lamination, Egg-shell effect, Corona, OWR as per the requirements.

- PARK offers a variety of media for air filtration, like HEPA/ULPA/HVAC, that meet or exceed different global standards, offering low pressure drop, energy saving and longer media life.

- Dust bag filter media (PET, PPS, P84, CPA, HPA, Glass Fiber, Meta Aramid, PTFE) for coal-fired power plants, dry cement kilns, asphalt plants, thermal power, waste incineration plants, chemical industry, steel industry, nonferrous smelting, aerospace, ceramic, glass industry, edible oil, food & beverage, pharmaceutical industry.

- Automotive Engine Air take Filter & Cabin Air filter System fulfill the requirements of EU9 and above. Activated Carbon Composite Cabin Air Filter Media can effectively remove gaseous & aerosol contaminations from air stream.

- Meltblown liquid filter media with calendared and uncalendared grades.

This content is sponsored by PARK Nonwoven.