In our current global marketplace and supply chains, consumers and users require some level of fluency in the terms and standards that define the products they acquire and use. Our filter market is no different.

While the design and variety of filters and the standards that govern their performance have expanded over the past several decades, the need for users to understand the prevailing terminology has grown more important. Unlike the traditional weights and measures, the terms that define the performance of a filter are not always understood. At the risk of offending my colleagues, I dare say, even professionals in the industry often misunderstand some of the terminology.

In this article, some of the more commonly misunderstood and misstated terminology is clarified.

High-efficiency filters, aka HEPA

At present, the marketplace uses the term HEPA loosely (Figure 1). The first high-efficiency filters came through the efforts of the U.S. military towards the end of World War II. Their efficiency was determined and specified according a prescriptive test method later written into the US Mil Std 282.

This method prescribes a vapor condensation method for generating a Dioctyl phthalate (DOP) challenge aerosol required for testing the filter. In this generator, DOP vapors are formed by heat and then cooled to form an aerosol with a relatively narrow particle size distribution. The aerosol concentrations upsteam and downstream of the filter were determined by a photometer, which is a multiple particle integrating optical scattering device. The size distribution of the challenge aerosol is verified by measuring the polarizing angle of white light by the aerosol. For reasons unclear, this was set as 29˚. The airflow and the other settings of the generator can be adjusted to achieve this requirement. This standard is still valid since introduced in 1952. The efficiency of these high efficiency filters (later termed HEPA) are 99.97% when tested according to this method.

Now for the common misconceptions and errors … Since the aerosol is generated by heating DOP, the test method is also colloquially called the ‘Hot DOP’ or ‘Thermal DOP’ test. The aerosol nor the test are ‘hot.’

The efficiency of ventilation filters is almost always determined using OPCs and a test aerosol, such as a salt or oil. These measures are not PM efficiencies. Some preliminary efficiency measurements have shown that the gravimetric measurements along methods prescribed for PM can be quite a bit lower than that computed from OPC measurements common to all filter standards.

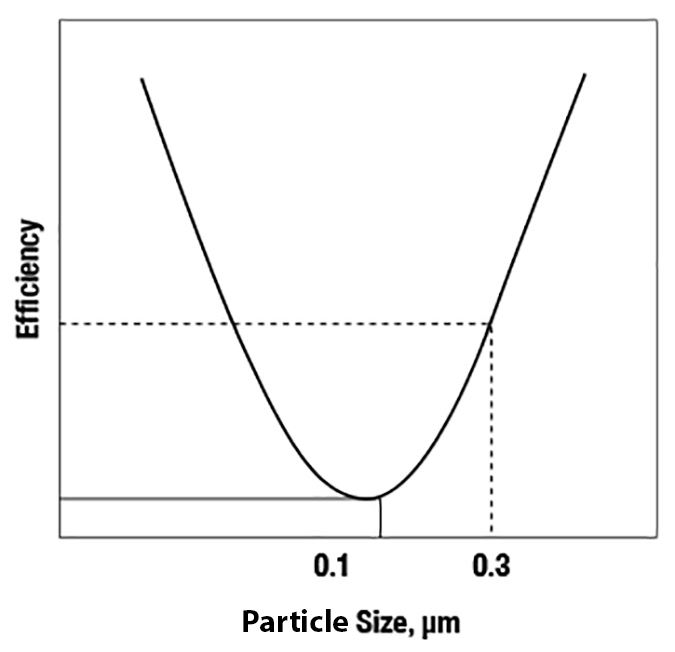

HEPA filter efficiency is not measured at 0.3 µm: From size distribution measurements, the mass median diameter of the DOP aerosol noted above was determined to be around 0.3 µm with a count median diameter under 0.2 µm. Hence the common practice of saying a HEPA filter is tested at 0.3 µm is incorrect. The efficiency of a filter tested at this larger size will be higher than if it was tested as specified. This concept is illustrated in Figure 2.

Photometer does not measure mass: A photometer is an optical scattering device. It measures the concentration of the aerosol as opposed to single particles. The response of a photometer for monodisperse aerosol varies approximately as the cube of the mean diameter in the particle sizes of interest in filter testing and IAQ. Hence it is often mistakenly assumed to measure mass. That these devices are calibrated according gravimetric measurements on a known aerosol adds to this misconception. In certain applications, such as workplace dust exposure, this response of a photometer has been used as a measure of potential exposure to workplace aerosols. Nevertheless, photometers do not measure aerosol mass directly, and neither is the original HEPA filter test a mass based efficiency method.

Are lower efficiency filters also HEPA?: In some markets, any filter tested according to a HEPA filter test method has been erroneously termed HEPA, regardless of whether they met all the test criteria or minimum efficiency. In my opinion, the advent of the EN1822 standard, which classified filters with even efficiency of 85% as HEPA (H10), seemed to sanction naming virtually all high-efficiency filters as HEPA. It should be noted that the more recent revisions of the standard have renamed these as E Class filters, but the damage has been done.

PM

PM2.5 and PM10 are statutory ambient air quality standards for particulate matter. They are measured according to prescribed methods or approved equivalents. PM is a gravimetric measure of ambient particulate matter separated according to their aerodynamic size into the 2.5 and 10 µm sizes. Although widely used, there are no PM standards or regulations for indoor air or air filters.

Optical Particle Counters and PM: Optical particle counters (OPC) measure the optical scattering diameter of the particle. The measured size depends on several properties of the particle including its shape and the refractive index of the material. Most indoor air quality and filter performance measurements rely on OPCs. Although one may convert the data to a mass by some assumptions, the result is not the same as PM. The differences between OPC measurements and PM on the same aerosol can be quite significant. Nevertheless, while the OPC data may be useful and valuable themselves, they are not a valid measure of PM2.5 and PM10.

If the measured aerosol is perfectly spherical, has a known density, and has ideal optical scattering properties, one may be able to compute a result that is close to the PM, but it would still not be considered an equivalent PM.

Filter efficiency: The efficiency of ventilation filters is almost always determined using OPCs and a test aerosol, such as a salt or oil. These measures are not efficiencies at PM. Some preliminary efficiency measurements have shown that the gravimetric measurements according to methods prescribed for PM can be quite a bit lower than that computed from OPC measurements, which are common in all filter standards

PM and ePM: The ISO standard classifies filter performance at an ePM. This ePM is not PM, but is a calculated value obtained by overlaying the OPC measured fractional filter efficiency data on a global average of ambient particle size distribution, presumed to be PM. Unfortunately, of late ePM and PM have been used interchangeably in commercial and technical literature, especially in Europe, leading to the misuse of PM.

In summary, popular usage notwithstanding, the terms HEPA and PM have specific and prescriptive meaning. Similar sounding terms, such as ePM, HEPA like, HEPA at 0.3 µm, and others, have added to the obfuscation of the original terminology. Regardless, a good understanding of these terms, both the original and the misused, will enable the user to obtain desired filters and specify required air quality, no matter what the producer calls them.

![Figure 1: Heat Exchanger Proventics GMBH.[22]](https://www.filtnews.com/wp-content/uploads/IFN_2_2024_crimpedmicrofiberyarns_Fig.-1-Heat-exchanger-225x125.jpg)