The true cost of a gas turbine inlet filters can be affected by a large number of factors. These factors are not constants; they are changing. The filter purchaser is challenged to not only identify these factors, but also keep up with the pace of change.

Large gas turbines are used by utilities to generate electricity. Smaller gas turbines drive pumps and compressors in locations with extreme conditions, such as desert dust, artic snow or sea spray on an oil rig. As turbines have become more efficient, they have become more susceptible to damage from contaminants in the combustion air. This ambient air from the surrounding environment can contain high dust loads. In California with its very tight emission standards, the particulate in the inlet air to the turbine can exceed emission limits. Thus, the gas turbine has to act as an air-cleaning device.

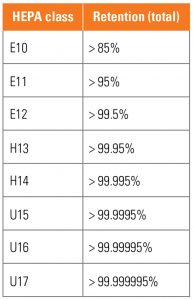

The challenge for gas turbine inlet fiber, media and filter suppliers is to increase gas turbine availability in all environments with newer and more sensitive gas turbines. The newer turbine designs are negatively impacted by small particles. This has led to the use of HEPA filters with efficiencies classed as H10/E10 and higher.

Studies show that turbine maintenance can be reduced with even higher efficiency E12-U17. One study showed that even if the cost of higher efficiency filtration were four times higher than lower efficiency, the true cost would be lower.

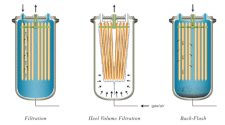

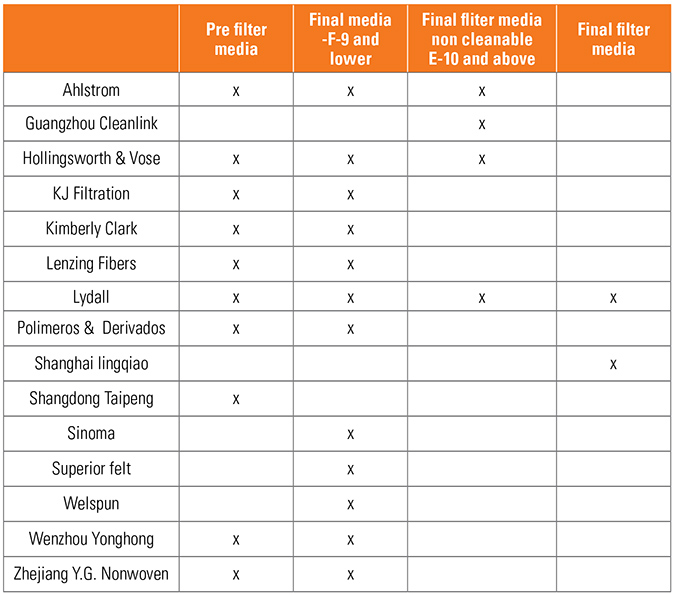

One can choose a system with noncleanable filters. They are relatively inexpensive, but require continuous filter replacement. By using a sequence of inefficient, but inexpensive, pre filters and a final high-efficiency filter, the replacement cost can be minimized.

An alternative is to use a cleanable filter. Periodic air pulsing knocks off accumulated dust. These systems are available from many suppliers if the F-9 efficiency is all that is desired. Cleanable filters with H12 efficiency are available from only a few suppliers. However, there are many new developments currently in progress that will expand the number of choices.

The cost of shutting down a turbine and washing the blades frequently is more than the cost of the inlet filters. Damage to the turbine blades can be even more expensive. So the value of increased efficiency is high. However, the cost of frequent filter replacement can also be high. Each of the many options has positive and negative aspects.

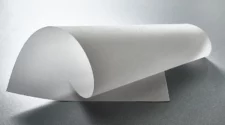

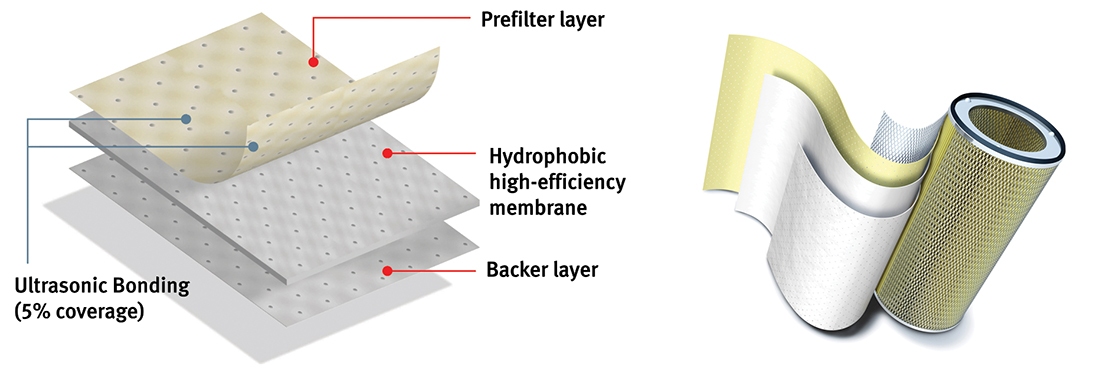

In terms of high-efficiency dust capture mechanisms, there is a choice between wet-laid glass and synthetic nanofiber nonwoven laminates or membranes. The traditional glass media for HEPA filtration has been used primarily in noncleanable filters.

The many factors and media choices for gas turbine applications have been discussed in a background document on display at http://bit.ly/mcilvaine-gasturbine.

The cost of shutting down a turbine and washing the blades frequently is more than the cost of the inlet filters. Damage to the turbine blades can be even more expensive. So the value of increased efficiency is high. However, the cost of frequent filter replacement can also be high. Each of the many options has positive and negative aspects. In each case, the impacts on the turbine have to be weighed against the true cost of the filter operation.

The assessment has to be continuous for two reasons:

- Turbine design keeps changing

- Filter system and component designs keep improving

As turbines are improved to increase efficiency, the impact of small particles also increases. So filter technology has to keep pace with turbine evolution. With many new filter and media designs being made available, their true cost has to be continually assessed.

In the past, the most efficient filters were rated F-9 with efficiency of more than 95% on particles 0.4 um diameter. The most penetrating particle size is about 0.2 um where the efficiency is much lower. Higher efficiency filters are rated based on the most penetrating particle size as follows:

Membrane laminates, such as those used for dust collection, can meet efficiencies up to E-12. The question is whether this is sufficient?

A number of fiber, media and filter suppliers for gas turbine inlets have already contracted for stands at FiltXPO, Feb. 26-28, 2020, in Chicago. Some are supplying just fibers; others supply media, a few are supplying the final filters. They have been categorized by level of efficiency.

International Filtration News and Mcilvaine Co. are creating a system to provide assistance to gas turbine inlet filter decision makers. This article is an introduction to the program, which will include a continuously updated “Gas Turbine Inlet Filter True Cost Decision Guide.” Stay tuned for more to come …

Start Your ’True Cost’ Program Now!

This report covers the markets and technology for purifying indoor air. Thousands of forecasts for three different types of media, as well as adsorbers and electronic air cleaners, for 80 countries and regions. Further segmentation for each application from residential furnace filters to ultrapure air in semiconductor plants. The report includes sections on gas turbines with both MW and $ forecasts, as well as a directory and market share reports.

You also receive:

- Insights based on continuous analysis since 1976

- Bottoms up forecasting thanks to complimentary technical analyses and project tracking

- Free 30 minute tutorial through GoToMeeting

- One free Excel table with more than 50,000 forecasts covering each product in each country in each industry

- Quarterly excel tables available at nominal cost

![Figure 1: Heat Exchanger Proventics GMBH.[22]](https://www.filtnews.com/wp-content/uploads/IFN_2_2024_crimpedmicrofiberyarns_Fig.-1-Heat-exchanger-225x125.jpg)