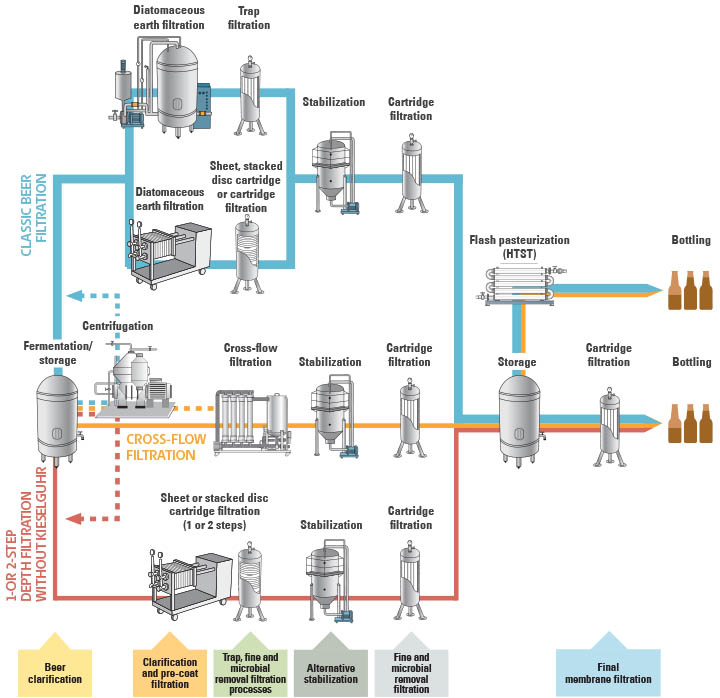

Filtration is a key part of the brewing process. Regardless of how the beer is brewed, microbiological stabilization is always conducted – whether using flash pasteurization or cold-sterile membrane filtration – prior to bottling. This ensures quality standards are maintained along with the health and safety of consumers. These steps are also vital to the marketability of the final product, solidifying the taste, color and character of each beer a brewery produces, which is necessary for a stable shelf life and consistent overall product quality.

The Filtration Process Explained

Filtration is a multistep process employed at different stages of brewing to remove solids, microorganisms and turbidity-causing particles that spoil beer, provide the foundation for professional stabilization later in the process, extend shelf life and produce a more flavorful, full-bodied taste. When done correctly, it results in consistent quality and taste, as well as time, cost and logistic resources required for production.

Filtration steps include:

- Centrifuge (optional)

- Clarifying and precoat (or crossflow) filtration

- Trap, fine and microbial removal filtration

- Alternative stabilization

- Fine and microbial removal filtration

- Membrane filtration or flash pasteurization (HTST) before bottling

Often during the first step in the process, a centrifuge is used to remove potential turbidity-causing particles that can unfavorably alter the taste and quality of beer once it matures. Remaining particles and yeast are gradually filtered out in subsequent steps.

The most common filtration method regardless of businesses’ size, however, is precoat filtration with diatomaceous earth. This approach offers breweries a variety of advantages, including the ability of cellulose, perlite or diatomaceous earth to be used in combination with stabilization aids for protein and phenol stabilization.

Clarifying Filtration Removes Yeast and Byproducts

Clarifying filtration (precoat) removes coarse suspended solids – mainly yeasts and fermentation byproducts, but also other suspended solids such as malt and hops residues – resulting from sedimentation, fermentation or subsequent storage. It can also be used to remove young, still-active yeast that forms a sediment after the fermentation process. Once harvested, that yeast can be used for additional fermentation processes, saving breweries money and ensuring consistency in beer quality.

Clarification filtration is typically based on one of two filtration technologies when brewing beer: crossflow filtration or precoat filtration using filter aids such as diatomaceous earth, cellulose and perlite.

Crossflow filtration can be implemented while maintaining low personnel costs but is used primarily in large breweries due to its high investment costs. Utilization of this method has grown in recent years and is now more in demand than ever before.

The most common filtration method regardless of businesses’ size, however, is precoat filtration with diatomaceous earth. This approach offers breweries a variety of advantages, including the ability of cellulose, perlite or diatomaceous earth to be used in combination with stabilization aids for protein and phenol stabilization.

Optimizing Precoat Filtration

Classic precoat filtration with diatomaceous earth involves using a triple-layer filter cake: a first and second precoating along with subsequent, continuous dosing of product filtration. The initial precoating is performed using coarse diatomaceous earth with an average permeability of 1.3 to 1.5 darcys to produce a stable filter cake on the support sheets or the metal or plastic sieves of the filtration systems. Cellulose or perlite are often added along with the diatomaceous earth to metal sieves to aid with cleaning.

During this first precoat, the flow rate is of particular importance. If too slow, the filter aids become uneven, resulting, in some instances, in undesirable results, like leaks and/or cloudiness. To maintain appropriate flow rates, a system pressure of at least 29 psi (2 bar) is recommended, along with double the rate of the subsequent product filtration. If, depending on the system, 0.11 to 0.17 gal/ft²/h (4.5 to 7 hl/m²/h) or more is used for precoating, beer filtration should be between 0.07 and 0.12 gal/ft²/h (3 and 5 hl/m²/h).

The second precoating is conducted using finer diatomaceous earth with an average permeability of 0.2 to 0.3 darcy to create the second layer of the filter cake. If the beer requires protein or phenol stabilization, silica gel or polyvinylpolypyrrolidone (PVPP) can be added to improve filtration performance and reduce the amount of diatomaceous earth necessary.

While this dosing varies, the typical recommendation is 0.13 to 0.16 lb./ft2 (600 to 800 g/m²) coarse diatomaceous earth, 0.13 to 0.16 lb./ft2 (600 to 800 g/m²) fine to medium-fine diatomaceous earth; for continuous dosing 0.67 to 1.34 lb./100 gal/h (80 to 160 g/hl/h) diatomaceous earth in the same way as the second precoating and an additional 0.25 to 0.75 lb./100 gal/h (30 to 90 g/hl/h) silica gel and/or 0.08 to 0.33 lb./100 gal/h (10 to 40 g/hl/h) PVPP.

Trap Filtration Removes Fine Particles

Carried out multiple times before different process steps or performed as an optional step before bottling, breweries often follow classic diatomaceous earth filtration with trap filtration using filter cartridges after fermentation and storage to remove finer particles. These precipitations can arise during storage, build up during clarifying filtration with diatomaceous earth, or tannin-protein complexes and thermal deposits (burnoff) that result in browning can be fueled during HTST. Today, the industry-standard retention rate is 3 to 10 µm.

There are three types of depth filter cartridges:

- Pleated: Large surface areas but usually only back flushable under certain conditions, which impacts cleaning and service and also complicates automating the regeneration process.

- Meltblown: Offers up to four gradations from coarse to fine and can be back flushed.

- Fleece-wrapped: Wrapped up to 24 times in graduations, forming an efficient funnel to retain a range of particle sizes. Easy to clean when back flushing using both hot and cold water.

Naturally, some coarse suspended solids sink to the bottom of the fermentation tank during sedimentation and need to be separated before clarifying filtration using a centrifuge. Subsequent filtration removes suspended particles that do not form sediment during maturation and storage.

Fine Filtration for the Finishing Touch

There’s one additional stage before filling bottles, kegs and tanks: fine filtration. This allows breweries to optimize both the quality and the overall taste of their product.

Ultimately, fine filtration reduces the amount of yeast – above a retention rate of 1.2 µm; if the rate is between 0.4 and 0.3 µm, it reduces the number of microbes – as well as bacteria and unwanted agglomerates from protein-tanning processes, to eliminate turbidity at the end of the brewing process. The color and turbidity of beer and wort, indicated by the European Brewery Convention (EBC) value, can be deliberately influenced by the degree of fine filtration.

At this stage, three methods can be used to separate particles, turbidity and microorganisms from beer:

- Mechanical separation on the surface (surface filtration). This is the most used mechanism and is found in most commercial filter media.

- Mechanical separation – a second type of mechanical separation mechanism – in the inner hollow space structure of the filter media (depth filtration). Depth filter media made of pure cellulose retains yeast and solids and removes fewer hop oils than mineral-based filter media.

- Adsorptive separation using positive zeta potential (electrokinetic potential), which is only achievable if depth filter sheets or stacked disc cartridges are used.

While it is difficult to rate the different filtration methods in terms of quality, it is possible to compare filter media options using water throughput. Under defined conditions (∆p = gpm/ft² at 14.5 psi and 68°F or ∆p = l/m²/min at 100 kPa = 1 bar and 20°C ambient temperature), water throughput is also an indication of the fineness of the filter. If the value is within a range of between approximately 0.5 and 3.7 gpm/ft² (20 and 150 l/m²/min), fine filtration and a microbial removal effect can be assumed, though only confirmed by performing a special microbiological analysis and evaluation, during which the Log Reduction Value (LRV) is evaluated using a test microbe. For beer, cultured yeasts or malolactic bacteria are usually used and their retention rates measured. Values between 0.3 and 5 µm are considered industry standard.

Additional filtration steps using filter cartridges deliver an enhanced level of purity, reduce turbidity and remove remaining microorganisms. A final membrane filtration stabilizes the beer against microbiological aging, which can drastically shorten its shelf life by causing spoilage.

Deciding which process is the best fit for your brewery depends on investment and operational costs, the desire for implementing automation, resource consumption, maintenance costs and your own expertise.

Sterilized, Shelf-Stable and Ready for Market

To ensure beer is sterile prior to bottling, there are two well-established practices: flash pasteurization (HTST) and membrane filtration. Both have the same goal: reducing beer-spoiling microorganisms to confirm microbiological stability, and thus quality, as well as to extend the product’s shelf life. This means killing malolactic bacteria, acetic acid bacteria and yeasts, which can multiply and negatively affect beer flavor. Each process makes beer easier to handle, transport and sell, because sterility is required for beer to be transported and stored unrefrigerated.

Flash Pasteurization (HTST): In this process, beer is heated to 162°F to 167°F (72°C to 75°C) for a defined period to kill harmful microorganisms and eliminate fluctuations in quality created during previous stages of the brewing process, such as fine filtration. While necessary prior to bottling, HTST does have one drawback: Because heating and cooling the beer requires a lot of energy typically obtained from fossil fuels, it comes with a heavy carbon footprint and has a poor impact on the environment.

Membrane Filtration: This method has a far less energy-intensive process, though it has not been used for quite as long. During membrane filtration, unfiltered beer flows through a filter cartridge with a defined pore size that retains yeasts and other bacteria. This tends to result in a higher-quality alternative that’s also cost-effective with a smaller carbon footprint. These filter membranes are often made of one of four materials: Hydrophilic polyether sulfone (PES), hydrophilic polyvinylidene fluoride (PVDF), single-layer or double-layer nylon 66 (polyamide 66), and single-layer or double-layer cellulose acetate (CA).

Since being introduced to the market 20 years ago, membrane filtration is being used by more brewers because of its high degree of automation, reproducible process conditions and consistently high quality – making the brewing process safe and efficient.

The filtration processes used during brewing depend on what works best for your operation. While each impacts the taste and quality of the final brewed product, they also require different levels of cost and resource expenditure investments.

Because the microbiological retention of the cartridges used can be clearly determined by a defined pore size, membrane filtration is a more reliable method for increasing product safety. Filter cartridges can be checked against specific quality standards using destructive or nondestructive tests, meaning they:

- Can be tested for integrity

- Enable validated microbiological retention (bacteria retention rate or LRV = log reduction value)

- Ensure high mechanical and thermal stability

- Offer high chemical stability

Because these filter cartridges are critical to beer quality, high standards are applied to their functioning and mechanical, thermal and chemical stability. Thus, filter cartridges must be able to withstand, e.g., 72.5 psi at 68°F (5 bar at 20°C) of pressure. If this difference is not exceeded, the cartridge is mechanically stable.

Additionally, their thermal stability (up to 100 steaming cycles) is also guaranteed, depending on the manufacturer. After each thermal treatment, however, be sure to evaluate the integrity of your membrane filter cartridge.

Chemical stability is also important for keeping membrane filter cartridges from being clogged following numerous filtration and cleaning cycles. Chemical cleaning agents are used for regeneration with the addition of enzymes that filter cartridges must be able to withstand.

The filtration processes used during brewing depend on what works best for your operation. While each impacts the taste and quality of the final brewed product, they also require different levels of cost and resource expenditure investments.