In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg: ken@filtnews.com

Most recent update: June 23, 2023

Ember Infrastructure Acquires Ground/Water Treatment & Technology

Ground/Water Treatment & Technology, LLC (GWTT) announced it has received a majority growth investment from funds managed by Ember Infrastructure (Ember). Ember’s investment will enhance GWTT’s ability to deliver its full suite of water management solutions to new and existing customers.

GWTT is a full-service provider of commercial water treatment services, including process and design engineering, system construction and startup, operations & maintenance, system optimization, and equipment sales and rentals. GWTT self-performs the vast majority of critical-path project milestones, mitigating risk and simplifying logistical challenges. GWTT has 25+ years of experience partnering with clients to solve complex water treatment challenges, including the cleanup of Superfund and former manufactured gas plant sites, civil and infrastructure dewatering, coal ash pond closure, and treating for emerging contaminants of concern that include PFAS compounds, 1,4-dioxane, hexavalent chromium, and many others, addressing some of the most important water quality challenges in the United States.

GWTT has been ranked in the Engineering News-Record Top 200 Environmental Firms (ENR 200) in each of the last six years.

FILTECH 2024 Scheduled for November 12-14

FILTECH 2024, slated for November 12-14, 2024, will offer a unique opportunity for professionals from a wide range of industries to expand their knowledge, discover new trends and gain valuable insights into the future of filtration and separation technology.

“FILTECH has firmly established itself as a global meeting place for experts and decision-makers in the filtration industry,” said Suzanne Abetz of FILTECH Exhibitions Germany. “We are thrilled about the great reception the event is receiving. FILTECH 2024 will provide exhibitors and speakers alike with the opportunity to showcase groundbreaking innovations and solutions and make valuable business contacts.”

“We expect more than 460 exhibitors at the upcoming show and will provide additional exhibition space,” added Abetz. “Already more than a year before the start of the event, exhibitors and visitors are showing an exceptionally high level of interest. A large part of the exhibitor space is already fully booked, which proves the high demand and the confidence of the companies in the importance of FILTECH as a leading industry platform.”

FILTECH 2024 also promises a diverse program of technical presentations, panel discussions and poster sessions. Abstracts can be submitted until May 2024.

FILTECH 2023, which was held in Cologne 14–16 February 2023, had 438 exhibitors, 160 speakers and 16,750 participants.

DESOTEC Completes Acquisition of Evoqua’s Carbon Reactivation and Exchange Services Business

DESOTEC, a leading provider in sustainable mobile filtration solutions in Europe, announced the completion of the acquisition of the carbon reactivation and exchange services business of Evoqua Water Technologies. With the integration of this US-based organization, DESOTEC broadens its horizon as it takes its first steps into a new continent.

Evoqua Water Technologies is a renowned leader in mission-critical water and wastewater treatment solutions with a wealth of expertise and a strong product portfolio in the US. The acquisition includes Evoqua’s product lines’ workforce, reactivation facilities and associated equipment in Darlington (Pennsylvania) and Parker (Arizona), and the reactivation and carbon vessel manufacturing facility in Red Bluff (California). Upon closing, DESOTEC can now provide the necessary solutions to the growing filtration demands in North America by leveraging its extensive expertise in Europe, built up over many decades.

Through a unique, flexible, and circular service concept, DESOTEC unburdens its industrial clients. With its broad range of mobile filtration solutions, the environmental services company supports its clients in their efforts to enhance the sustainability of their operations or products. In addition, it helps companies comply with environmental regulations and sustainability requirements. As of today, DESOTEC employs a total of 355 employees.

INDA Receives United Nations Accreditation; Participates in Plastics Treaty Negotiations

INDA, the Association of the Nonwoven Fabrics Industry, was granted status last month as an accredited stakeholder with the United Nations Environment Programme (UNEP), which, among other privileges, will allow representatives from the association to observe the formal ongoing negotiations of the UN Global Plastics Treaty.

INDA Government Affairs Director Wes Fisher was on site at the second session of the treaty negotiations formally titled the “second session of the Intergovernmental Negotiating Committee to develop an international legally binding instrument on plastic pollution, including in the marine environment.” The negotiations took place from May 29 to June 2, 2023 at the United Nations Educational, Scientific and Cultural Organization (UNESCO) Headquarters in Paris, France.

“We are excited to continue to enhance the capacity of INDA’s government affairs department to better serve the industry on a global scale,” said Fisher. “We look forward to working with the UNEP to provide technical input regarding ongoing plastics treaty issues specific to the nonwovens industry, and engaging with other UN processes with our new status as an accredited stakeholder.”

Veolia to Deliver Third Largest Desalination Plant in UAE

Veolia, a leader in water technologies, will lead, via its subsidiary SIDEM, a consortium in charge of the engineering, procurement and construction (EPC) on the Mirfa 2 desalination project commissioned by Abu Dhabi National Energy Company PJSC (TAQA) and ENGIE. Located in Abu Dhabi, this state-of-the-art Reverse Osmosis Desalination will be the third-largest desalination plant in the United Arab Emirates (UAE). With a production capacity of 550,000 cubic meters per day of potable water, it will provide clean drinking water to approximately 210,000 households while offering increased efficiency and a reduced environmental footprint. The contract represents revenue of approximately 300 million euros for Veolia. Project construction will begin in Q2 2023 so the plant can be commissioned by 2025.

Most of the drinking water used in the UAE comes from the sea. To manage the growth in water consumption and to compensate for the aging of existing facilities, mainly thermal desalination plants, the country has decided to use the latest advanced technologies and engineering processes to increase its desalination capacity while reducing its energy consumption. A strategy that strongly supports the country’s 2050 carbon neutrality ambition.

Relying on Veolia’s worldwide expertise in water desalination, the Mirfa 2 plant will follow the latest developments in environmental and efficiency standards for desalination, featuring advanced technological processes such as reverse osmosis, which represents strong efficiency gains compared to traditional thermal desalination, to lower energy consumption and improve productivity. These technological advancements allow to slash energy use by 80% compared to the 1980s, when thermal desalination was predominant.

Novasep Process Solutions Renamed Applexion

Novasep Process Solutions, a provider of liquid separation and purification solutions has been renamed after its carve out from Axplora Group and become Applexion.

Headquarters in Saint-Maurice de Beynost, France, Applexion is a global supplier of purification technologies such as chromatography, ion exchange and ceramic membrane filtration. For the last 15 years, it has designed, built and commissioned more than 600 units all over the world.

Bridgepoint, Applexion’s majority shareholder, has renewed its support and commitment to the business.

Damien Brichant, president of Applexion, said: “Bridgepoint is now enabling us to finalize our transformation into an equipment and services-oriented company, focusing on decarbonization challenges from our customers. Applexion unveils its new identity, a reminder of our technological and entrepreneurial origins, and confirms the launch of our new offering and innovative digital services that will benefit our customers, throughout the lifecycle of their equipment.”

Samsung Launches Less Microfiber™ Filter to Protect Oceans from Laundry Plastics

Samsung Electronics announced the launch of the new Less Microfiber™ Filter, an external washing machine filter designed to significantly reduce plastic microfiber emissions during laundry cycles. Designed with inspiration from apparel maker Patagonia and expertise from the global ocean conservation organization Ocean Wise, the filter builds on the success of last year’s Less Microfiber™ Cycle to substantially cut microplastics and enable sustainable laundry washing that is both effective and effortless. The new filter is now available in Korea and the U.K. and will roll out to other countries in the third quarter.

“With microplastics emissions to our oceans continuing to increase and regulations being strengthened in many countries, as well as microplastics becoming a growing health concern for people everywhere, Samsung worked with Ocean Wise and Patagonia to engineer technology to prevent the release of microplastics from our daily life,” said Moohyung Lee, Executive Vice President and Head of R&D Team of Digital Appliances Business at Samsung Electronics. “With innovations like the Less Microfiber™ Filter and Cycle, Samsung is enabling Everyday Sustainability in a wider array of products and making eco-conscious daily practices second nature in the home.”

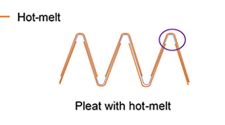

To enable customers to cut microplastic emissions from their laundry, Samsung first developed the Less Microfiber™ Cycle, a wash course that reduces microplastic shedding by 54% in part by leveraging Samsung’s proprietary Ecobubble™ technology. By using bubbles to help dissolve and absorb detergent, less heat and energy is required to wash clothes, resulting in reduced abrasion which in turn prevents microplastic emissions.

The Less Microfiber™ Filter takes this a step further, preventing up to 98% of microplastics released during laundry from escaping into the ocean, equivalent to eight 500ml plastic bottles per year3 when used four times a week. In addition, to help more customers get involved in cutting microplastic emissions, the Less Microfiber™ Filter has a mountable design style that allows it to be used with standard washing machine models, demonstrating the company’s dedication to long-term sustainability and helping customers embrace sustainability at home.

MAAG Group Expands in China

The MAAG Group is expanding its presence in China creating the prerequisites for continued growth in the People’s Republic. Particular focus is being placed on creating incremental production capacity and on the introduction of new products specifically for the Chinese market.

The internationally operating MAAG Group, headquartered in Oberglatt, Switzerland, has been stepping up its localization strategy in China since 2022 and currently has 103 employees. One recent example: the assembly shop at the site in Jiading, a district of Shanghai, has recently doubled in size.

“With this expansion, MAAG is now well positioned for the further expansion of its localization activities in China,” explains Ueli Thürig, President of the MAAG Group. “‘Made in China for China’ is one of the key strategies our company has been focusing on in recent years; more than 90 percent of the equipment assembled in our Shanghai plant is intended for the Chinese market.”

Expanding the market-specific product range MAAG has already been producing GA series extrusion pumps, BAOLI strand pelletizers, and ZHULI underwater pelletizers in China. A similarly adapted version of the proven M-USG underwater strand pelletizing system will now expand the market-specific portfolio as the C-USG.

The original German design will form the basis for this new version. While some key components will be supplied from Germany, the majority of parts will come from local production. The first C-USG systems will be delivered to customers at the end of 2023.

In addition, the added space will accommodate a new service center for the Maag/Ettlinger recycling filter to enable MAAG to serve local customers more quickly. MAAG is responding to the increased number of continuous melt filters installed across Asia.

3M Invests in Biopharma Filtration

Applying its leadership in biopharma filtration technology, 3M announced it will invest $146 million to expand its capabilities to further support biotech manufacturing, a fast-growing area of health care which is bringing breakthrough therapies to patients.

The investment will include facility and equipment improvements and the addition of 60 full-time positions in 3M manufacturing facilities in Europe.

The new investment will accelerate 3M’s development and delivery of vital filtration equipment designed for bioprocessing, biological and small molecule pharmaceutical manufacturing applications, which will enable biotech customers to continue to innovate therapies used for the treatment of conditions such as rheumatoid arthritis, multiple sclerosis, and certain cancers. Filtration and purification is essential in manufacturing biopharmaceutical drugs. The process uses a unique filter material that captures impurities while allowing the necessary drug substances to pass through.

Metso Breaks Ground on Mexico Factory

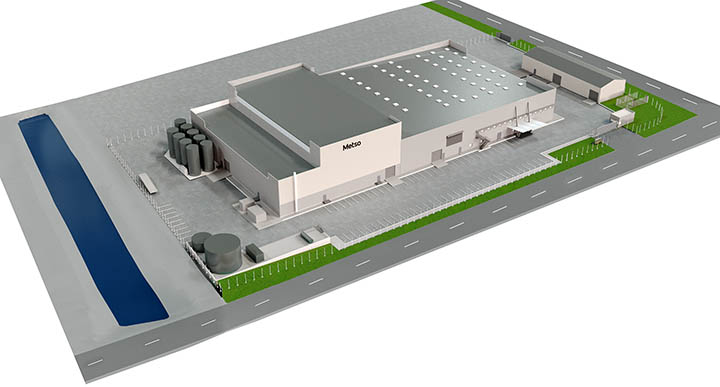

Just weeks after changing its name to Metso Corporation official, the former Metso Outotec has marked the groundbreaking for its first-ever polymer filter plate factory in the world in Irapuato, Mexico.

The facility, which will offer production process efficiency, quality, and service capability to support customers’ sustainability and operative targets, broke ground the last week of May. Plans for the $30 million project were first confirmed in September 2022.

Metso opted earlier this year to earmark an additional $9.6 million to boost the facility’s planned production capacity by 30%, thus responding in a better way to rising global market demands.

The new factory is located on a lot measuring more than 18,000 square meters and will have a factory and warehouse area of over 8,500 square meters. Metso has rubber and Poly-Met and screening media factories In the same industrial area in Irapuato, providing even more operative efficiency.

Xylem Completes Acquisition of Evoqua

Xylem Inc., a leading global water technology company announced it has completed its acquisition of Evoqua Water Technologies Corp., a leader in mission-critical water treatment solutions and services, in an all-stock transaction valued at approximately $7.5 billion. The combination creates the world’s most advanced platform of capabilities to address customers’ and communities’ critical water challenges.

Headquartered in Washington, D.C., the combined company becomes the world’s largest pure-play water technology company, with $7.3 billion in pro forma revenue and more than 22,000 employees globally. Xylem’s unmatched portfolio of innovative solutions across the water cycle, including advanced technologies, integrated services, and deep application expertise, will help customers in utilities, industrial and commercial end markets address their most pressing water needs.

New Pore size Instrument From Porometer

Porometer, a leading provider of pore size measurement solutions, has announced the launch of its latest product, the POROLUX™ Revo. Building on its reputation for innovation and cutting-edge technology, Porometer has developed a new instrument that takes pressure control to the next level, offering unrivalled accuracy and reproducibility in pore size measurement.

The POROLUX™ Revo features the patent pending MP² (Multistage Pressure Process) technology, which ensures a smooth pressure increase during the measurement process and speeds up the process of reaching flow and pressure stability.

This advanced pressure built-up process makes it possible to do measurements with smaller, perfectly uniform pressure steps, leading to the most accurate and reproducible pore size results.

One of the advantages of the MP² technology is the more gentle approach towards the desired pressure point, making it possible to register a data point even in the pore opening region. This results in a smoother wet and more detailed pore size distribution curves, providing users with even greater insights into their samples.