Did you know? In Scotland and Canada, it’s “whisky” … But in the Ireland, the U.S. and elsewhere, it’s “whiskey” … So while we’re not beyond the occasional typo here at IFN, in this case there is a method to our madness.

The filter practices and processes of whisky manufacturers are often closely guarded secrets in individual recipes, which have been developed and perfected over generations for a highly discerning market.

Scotland’s famous whisky distilleries are also subject to some of the most demanding environmental regulations in the world in respect of the discharge of wastewater into Highland streams and rivers.

Production

Whisky is distilled primarily from malted barley that is ground, mashed in a “mash tun,” fermented, distilled, matured and then vatted, before being bottled. Mashing involves the conversion of starch in the crushed grain (grist) into fermentable sugars by the addition of hot water. The sweet liquid (wort) is then separated from the solids (draff) and, after cooling, pumped into washbacks for fermentation. Three separate types of alcohol are obtained during fermenting and distillation, known as the “head,” “heart” and “tail.” The “heart” is what ends up in the bottle.

It is of prime importance that there are no visible particulates and no haze when the water is added, so filtration is employed at the vatting stage, often followed by chilling and further, finer filtering to remove fatty esters.

The individual distilleries of Scotland have all developed their own proprietary filtration methods about which they will say very little. All of the challenges of the haze, flavor and appearance of whisky, however, are solved with filtration, and an idea of its role in the process is hinted at by Fileder, based in Maidstone, UK, which has recently provided solutions to the Glen Moray distillery, which produces around six million liters of whisky each year.

Fileder supplied Glen Moray with standard polypropylene bag housings to prevent the residual grist blocking up the heat exchanger which cools down the wort prior to fermentation. A nylon filter housing was then installed to remove the grist from the water that is added to the mash tun. For the vatting, 200 micron filters are employed to take out the larger char particles and 50 micron filters for the smaller char particles.

Fileder advises that if the final whisky is to be below 46% ABV (alcohol by volume) then it should be chill filtered using large filter sheets protected by high-efficiency 20 micron-rated pleated cartridges to remove naturally occurring fatty esters, which cause clouding of the whisky when water or ice is added. With all spirits, before bottling there is a final guard filtration stage to trap any visible particles using 10-micron cartridges.

Ultrafiltration membranes separate the biomass generated in the biological state of the process. For Ardmore, which was founded in the late 19th century and is based in Kennethmount, Aberdeenshire, the high quality water that remains can be fed directly back into a nearby river with a clear conscience and full legal conformity.

Non-chilled preference

In the United States, exclusive bourbon, rye, and single-malt whiskeys often carry guarantees of being “non-chill filtered” on their labels, since there is a general perception that the process has a negative impact on flavor and taste. The key argument against it is that it removes the long-chain esters that are crucial to a whiskey’s flavor and mouthfeel.

Significantly, all of the exclusive U.S. whiskeys are stronger than 46 ABV – the so-called “floc point,” below which chemical compounds like fatty acids can clump together when bottles are stored at low temperatures, creating a cloudiness or haze to the spirit.

To be on the safe side, brands such as Jim Beam chills all of its whiskeys up to 50 ABV.

Not all exclusive U.S. brands agree that chill filtering is bad, however. Michter’s, for example, chill filters all of its whiskeys from its 42.4 ABV ranges of bourbon, rye and whisky right up to its cask-strength products, such as the 20-year-old bourbon it sold during 2019, which was 57.1 ABV.

The company argues that removing longer chain esters allows aspects of a whiskey to be showcased that would otherwise be masked by dominant characteristics.

“Each whiskey gets its own meticulous and specific filtration,” said Michter’s master of maturation Andrea Wilson in an interview with The Whisky Advocate. “When we develop new expressions, we go through an entire process that could take many months of understanding the chemistry and dealing in each variable to achieve the best representation of the whiskey.”

She added that Michter’s keeps its practices under wraps, but that they encompass everything from the temperature at which the filtration takes place to the materials from which the specific filters are made.

Aquabio

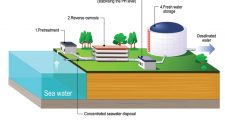

Wastewater filtration and treatment has meanwhile become increasingly important to the brand reputations and public image of Scotland’s whisky industry, as illustrated by recent installations at key brands Ardmore, Glennfiddich and Glenmorangie.

Both Ardmore and Glenmorangie have installed Aquabio technology from Viledon Water Solutions, part of the Freudenberg Filtration Group.

The key to Aquabio technology is a membrane bioreactor said to provide unprecedented energy and cost efficiency during operation.

Ultrafiltration membranes separate the biomass generated in the biological state of the process. For Ardmore, which was founded in the late 19th century and is based in Kennethmount, Aberdeenshire, the high quality water that remains can be fed directly back into a nearby river with a clear conscience and full legal conformity.

“At Ardmore we separate 99% of the organic constituents from the wastewater and also significantly reduce the copper residues, which is particularly important for the health of aquatic life,” said Juergen Abt, director of water solutions for Freudenberg Filtration Technologies, adding that the fully automatic operation of the plant and its real-time remote monitoring by the supplier’s technical experts was greatly appreciated by Ardmore.

“Thanks to the remote monitoring of all system components, process and quality changes can be recognized early,” Abt said. “This enables immediate measures to be taken to consistently ensure the high quality of the treated water. If there are any changes in the production schedule, the plant can be quickly adapted to the new conditions.”

Biomass

Glenmorangie has been distilling its well-known single malt whisky at Tain, in northern Scotland since 1843 and also employs Aquabio technology for its water purification.

The best solution for the distillery was identified as an anaerobic bioreactor, the low energy AnMBR LE, which purifies the wastewater by treating it and feeding it into a bioreactor. Bacteria then decompose the biomass and the water is separated from it by an ultrafiltration tube membrane. The resulting pure water can then be cost-efficiently treated and in addition, the biomass provides additional energy which is used for production.

Glenmorangie produces between 4-5 million liters of whisky, operating 24 hours, seven days a week.

The Aquabio membrane bioreactor can treat around 450 cubic meters of wastewater per day and is fully automatic. Like the installation at Ardmore, continuous monitoring allows changes to be reacted to immediately.

Modular media

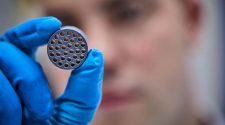

Glennfiddich, in Dufftown, commissioned 2H Water Technologies to supply a biological effluent treatment plant based on its modular BIOdek plastic filter media.

With over 20 stills, 45 warehouses and with an evaporator plant, an on-site cooperage, a copper smith and a number of bottling centers, this is one of Scotland’s largest whisky production facilities.

The plant met the requirement for sustainable, chemical-free and efficient wastewater treatment that removes biological and chemical oxygen demand from the liquid effluent to ensure wetland fauna and flora is not oxygen deprived and flourishes.

The structured, modular BIOdek media means the plant can be expanded easily and cost-effectively to meet any further increases in output or other changes in regulatory or operational demand.

Valuable exports

In a regular year – one that is not being warped by the COVID-19 pandemic – over 2,500 bottles of 70cl, above 40 ABV Scotch whisky are shipped to 175 markets around the world each minute, totaling around 1.3 billion annually. In 2019, the business was worth £4.9 billion in exports and £5.5 billion in gross added value to the UK economy.

There are currently 133 distilleries across Scotland employing 10,000 people directly, about two thirds of them in rural areas, providing vital employment and investment in communities.

To be called Scotch Whisky, the spirit must be matured in oak casks in Scotland for at least three years and the amount of casks currently in storage is pretty mind boggling.

Chivas Regal is made at the Strathisla distillery at Keith in Moray, the oldest, founded in 1786, and smallest working whisky distillery in a country of 5.5 million people.

There are currently more oak vats of Chivas Regal alone maturing in Scotland, than there are people.

![Figure 1: Differentiation with membranes based on the famous Robeson diagram that plots selectivity vs. permeability. From Reference. [4]](https://www.filtnews.com/wp-content/uploads/IFN_042023_membranes_Figure1-225x125.jpg)