University of Akron Chemical, Biomolecular & Corrosion Department Research Group: Multiphase and Filtration Group Professor/Advisor: George Chase, Ph.D.

AbdulAziz AlGhamdi earned a bachelor’s degree in Engineering from King AbdulAziz University, Jeddah, Saudi Arabia in 2011. He was awarded a scholarship from the government of Saudi Arabia to study for his master’s degree in Chemical Engineering at The University of Dayton (Ohio), where he worked in a project to test several industrial water pumps for vertical flow to reduce air content in multiphase air-water flow. AbdulAziz is now at the University of Akron, working under the supervision of Professor George Chase, Ph.D., in the field of the filtration research.

AbdulAziz’s current research is to investigate the effect of filter media thickness on filtration performance. Most filter designs have thick media to realize a high capture rate and ensure that drainage is controlled. Despite this, liquid holdup in a thick medium may result in a large pressure drop during some operations involving frequent flow interruptions. A better alternative is to design thin media filters which enable continuous gas flow through them. Experimental observations of thin glass media show oscillation behavior for pressure drop and liquid droplet concentration in the gas downstream. Additionally, it has been proposed to modify thin glass filters to improve their oscillation behavior through surface modifications.

Research overview

Liquid aerosols coalescing filters are made of material that is not only thicker than the drops themselves, but also holds the droplets transported by the air in place. When conditions are favorable, liquid can migrate through the filter, where solid particles tend to stick where captured. The captured droplets coalesce into larger drops and are pulled through by the airflow and gravity. By the time liquid reaches the exit surface, it starts to drain from the filter. Due to the liquid accumulating in the filter, the void space partially fills with liquid and the pressure drop for the airflow increases. Such filters eventually reach a quasi-steady-state performance (for operations with steady inlet flow conditions) in which the rate of liquid drainage from the filter becomes equal to the rate of liquid influx through the filter, and the pressure drop remains constant.

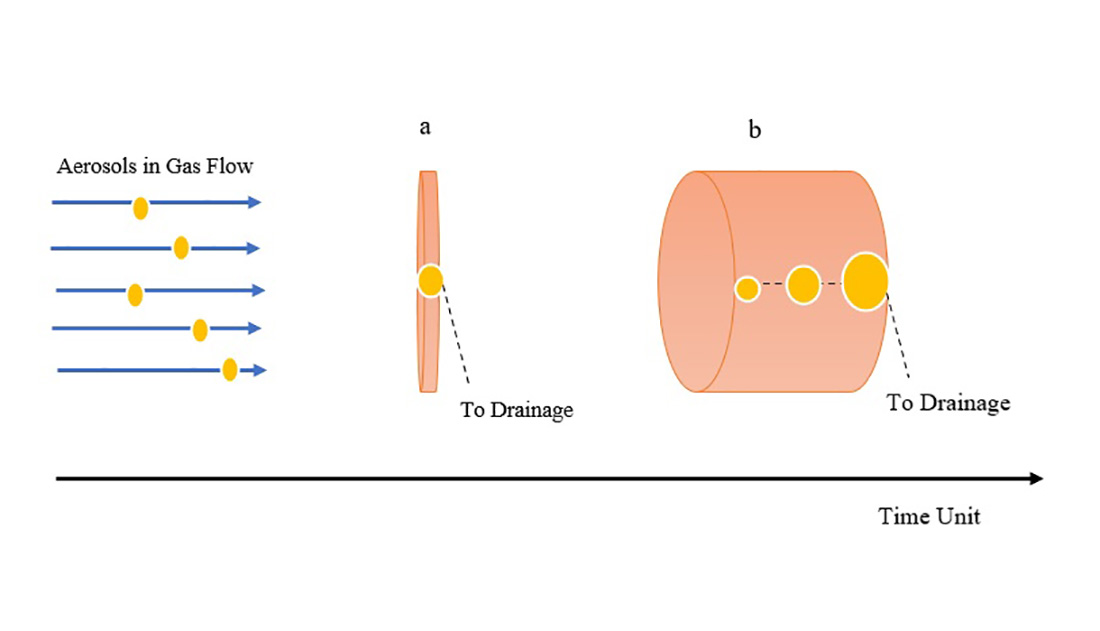

However, thin media exhibits an intriguing behavior. Thin media have a thickness that is about the same or less than the diameter of the coalesced liquid droplets. Because of air drag, liquid collects in thin media until it is large enough to move, and then drains immediately, opening the pore volume for air to flow. The filter then resumes catching droplets of liquid, resulting in a lower pressure drop and reduced local gas velocity. Consequently, a fluctuating pressure drop, and outlet concentration are observed.

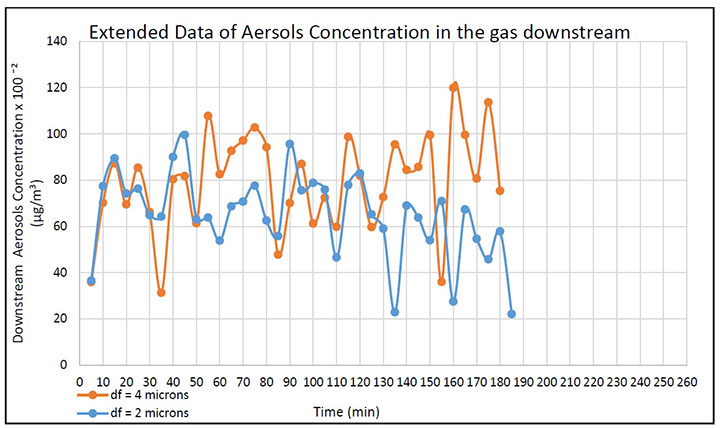

Although this is not always the function one desires from filter media, understanding this function is helpful in avoiding it in the future of filter designs. The conducted experimental research includes two fiber sizes to ensure any effect of the fiber diameter in droplet capturing. As shown in Figure 2, different fiber sizes of 2 microns, and 4 microns have been tested for a thin media of 1 mm thickness. Aerosols are in high concentration in gas downstream in large fiber size medium, due to high air permeability and porosity of the filter media.

A better alternative is to design thin media filters which enable continuous gas flow through them. Experimental observations of thin glass media show oscillation behavior for pressure drop and liquid droplet concentration in the gas downstream.

To further improve the liquid droplet capture through thin filter media, an undergoing research is conducted to modify the surface of the Glass fiber filter media to improve the coalescence of liquid droplets. Glass filter media surface has an oleophilic property which may allow liquid to migrate into the thin media in a short period of time, and this migration can be controlled by changing the surface wettability characteristics. As the contact angle of the glass filter surface is increased, it is possible for the liquid droplets to coalesce and penetrate for a longer period, which may improve the oscillatory behavior of the thin media.

Career goals

AbdulAziz has been conducting experiments in gas-liquid coalescing filtration with the aim of completing his Ph.D. requirement in spring of 2022. He has one research paper currently under peer review, and he has two additional research papers in development. AbdulAziz participated and presented a technical presentation through the American Filtration Society’s FiltCon 2019 conference held in Cherry Hill, New Jersey.

AbdulAziz anticipates working in academia with a focus on filtration and separation. Inspired to work as a post-doctoral researcher after graduation, AbdulAziz would like to expand his research skills working with other respected professors and mentors. He also looks forward to working on research to improve industrial applications in the area of sustainability.

![Figure 1: Heat Exchanger Proventics GMBH.[22]](https://www.filtnews.com/wp-content/uploads/IFN_2_2024_crimpedmicrofiberyarns_Fig.-1-Heat-exchanger-225x125.jpg)