As Brad Kalil of INDA noted in his analysis of the market in the November/December 2019 issue of IFN (pages 38-39), the key drivers of growth in the nonwoven filter media space are an increasing demand for cleaner air and water, economic and population growth and a growing awareness of the need to regularly replace filters.

Sensors

In a bid to encourage filter replacement, manufacturers are now increasingly taking advantage of sensor-based assistance.

3M, for example, has introduced the first-ever Bluetooth-enabled HVAC air filters. Its Filtrete-branded products are being integrated with Amazon’s dash replenishment service via a pressure sensor that, in combination with a special app, allows household consumers to track filter life based on airflow and usage, not just time.

Among recent developments from Minneapolis, Minnesota-headquartered Donaldson, is iCue, a subscription service which monitors industrial dust collectors with an accuracy said to far surpass traditional non-connected gauges, sending maintenance alerts directly to plant management teams. The information is designed to achieve energy savings by prompting timely maintenance – and of course filter replacement.

Similarly, for engine air filters, Donaldson’s wireless Filter Minder monitoring system is now being widely adopted by operators of professional truck fleets.

Battery power

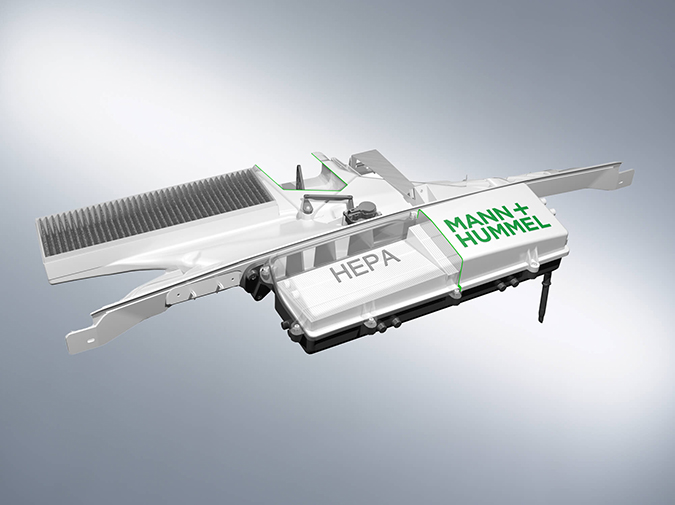

Sensors too, are to be found in the new FreciousSmart cabin filter system by Mann+Hummel, headquartered in Ludwigsburg, Germany.

One of the biggest challenges facing electric mobility, the company says, is in sufficiently extending the driving range of the vehicle. Batteries lose energy through heating, cooling and the cleaning of air, which enters the vehicle. Adequate filtration is, however, essential in order to protect vehicle occupants against air pollution and manufacturers are consequently seeking lower energy solutions.

The FreciousSmart system mainly operates the air conditioning system in recirculation mode and as a result, the energy consumption is greatly reduced and the service life of the filter elements extended. Sensors continuously monitor the quality of the ambient air and the air inside the vehicle, measuring the CO2 concentration, the relative humidity and the concentration of particles. If, for example, the CO2 exceeds a critical level above 0.1% of the volume, the inflow of ambient air is increased. Another sensor recognizes the degree of contamination of the ambient air with particles and pollutants, decides which filtration quality is required, and determines how much fresh air should enter the interior of the vehicle.

The FreciousSmart system has recently been specially adapted to the compact size of best-selling EV model, the Renault Zoe.

CareMetix

The constructions of cabin air filter media are becoming ever-more sophisticated, as is demonstrated by the latest CareMetix range from Mahle, headquartered in Stuttgart, Germany.

Mahle’s standard cabin filters are based on active carbon to ensure that as few pollutants as possible enter the driver’s cabin. They remove more than 90% of hazardous nitrogen oxides from the air before it is fed into the interior of the vehicle via ventilation.

CareMetix filters go a step further by both adsorbing gases but also neutralizing all types of odor as a result of their special five-layer structure.

As with other active carbon filters, a high-performance particulate filter layer for dust separation and two different active carbon layers which are effective against organic and inorganic gases are applied to the substrate layer. In addition, a molecular sieve mat ensures unique odor filtration.

Mahle has tailored the filtration action of CareMetix media to eliminate virtually all gases, which can occur when driving, protecting against unpleasant, pungent odors such as tar vapors and sulfur and ammonia gases. With 85 different CareMetix designs, the company already offers solutions for almost 75% of all passenger car models available in Europe.

Colback Plus

Also designed for cabin air filtration, in addition to room air and HVAC filters operating at low-to-medium efficiency levels, is Colback Plus from UK-headquartered Low & Bonar, a new pleatable support medium, which also has its own built-in filtration capability. This dual functionality reduces the number of layers that would normally be needed in a filter system and thanks to its unique construction, Colback Plus is adhesive-free.

Colback is already widely employed as a support medium in the filtration market as a result of its high stiffness, high air permeability and high thermal stability. Engineers at Low & Bonar have now extended its capabilities by adding a mechanically bonded microfiber layer, delivering a highly permeable support and filter layer in one.

The bonding technology reduces inefficiencies caused by the use of adhesives, or point bonding, such as VOCs or reduced pressure drop. The new product demonstrates high and stable filtration efficiency levels combined with high dust loading capacity. The microfiber layer is very uniform, for constant properties across the web, while the conventional Colback layer allows for fast pleating, with the formation of sharp and stable pleats for each filter.

Eurovent upgrade

The Eurovent RS4/C/001-2019 energy rating for air filters was updated at the start of 2019 and is no longer based on efficiency, as measured according to standard EN779, but linked to the efficiency measured according to ISO 16890.

This is having a positive impact on product development, in respect of both filtration performance and energy efficiency, according to Sandler, based in Schwarzenbach/Saale, Germany.

The company is meeting the new requirements with progressively structured pocket filter media containing fine fibers of less than 1µm, which attain high efficiency, as well as having high dust holding capacity. Sandler’s latest enAIRsave range includes products meeting all ISO 16890 efficiency ranges while being resistant to both temperature and moisture.

enAIRsave combines performance and reduced energy consumption with three filter layers providing optimum dust separation – not just in the fine fiber layer, but across the entire width of the medium. The particles are primarily deposited in the coarse meltblown layer as well as the pre-filter layer. As a result, air can still flow through the filter at a relatively low pressure and, consequently, at a reduced energy consumption.

In addition, the company’s pleatable nonwovens can be processed with all common pleating processes, with their fiber structure rendering the pleats highly stable and resistant to mechanical influences.

Lydall, headquartered in Manchester, Connecticut, has also tested its complete range of filter media grades – from efficiency ePM2,5 50% to ISO ePM1 80% – in both flat sheet form and as V bank filters, in response to the latest Eurovent requirements.

LydAir MG fiberglass media in the HD range allows filter manufacturers to obtain the desired ePM efficiency on the complete filter element at the lowest pressure drop. This low initial pressure drop and its optimized increase during the dust loading with fine dust is consequently meeting the required energy ratings of the filters when measured according to Eurovent RS4/C/001-2019.

Nanofibers

Hifyber, based in Denizli, Turkey, reports that to further reduce energy consumption, it has introduced high performance new nanofiber media for HVAC applications.

The company’s STP-4720 series is said to reach a new level of efficiency and low energy consumption by reducing particle concentrations in buildings while consuming less energy as a result of the relatively low air resistance of the media.

According to ISO 16890, the first pressure drop with Hifyber’s HF-STP-4720-09 coded media is almost half that of glass fiber filter media at 82 Pa and dust holding capacity at 200Pa is 316 grams. Another advantage of the STP-4720 series is its durability, in contrast to the delicate structures that restrict the use of nanofiber media in many commercial applications.

Vector

In other recent developments, the latest cartridge-type Vector filter of New York-headquartered Pall Corporation has been designed to replace traditional bag filters, providing significant performance improvements and energy savings.

The key to it is what the company calls “Ultipleat” technology, in which the pleats are tilted and partially laid over each other to fill more space within the overall structure. In addition, Vector filters have greater rigidity than filter bags and their reinforced sliding flanges and elastomer gaskets are a response to issues related to poor sealing in bag filters

The advanced filter technology allows for the filtration of an extended range of viscosities, while minimizing differential pressure, resulting in reduced energy losses and operational costs.

Micro-metal fibers

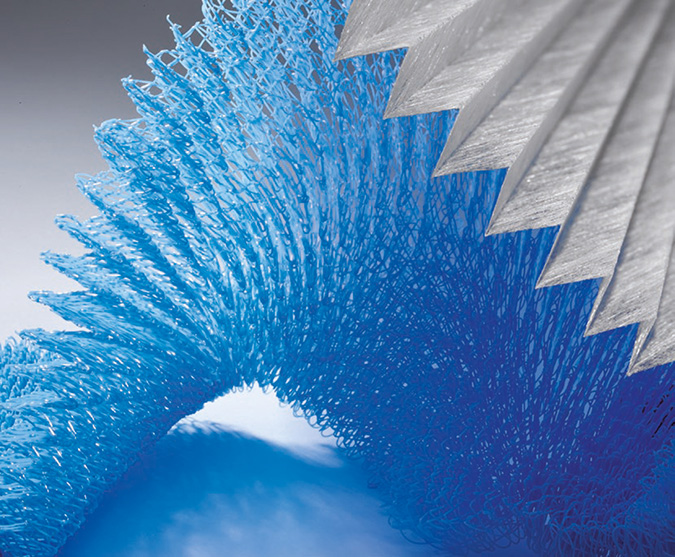

Finally, metallic microfibers manufactured by BinNova Metal Technology (MFT), of Jena in Germany are now being turned into wetlaid nonwovens for applications in electronics, filter technology, battery materials and catalytic processes.

Manufactured with a licensed technology from the Max Planck Institute in Germany, the fibers, made from a variety of different metals and alloys, are extremely fine, yet at the same time very robust.

The end-use applications for MFT nonwovens have high demands in terms of material properties such as alloy variety, elasticity and corrosion resistance and the production of such micro-metal fibers has previously only been possible with the aid of drawing or templating processes. These methods, however, are not suitable for guaranteeing all of the desired properties, while being complex and expensive.

MFT’s technology, in contrast, is based on a metal spinning process in which a metal smelt is applied to a cooled, rotating copper wheel via a nozzle.

The smelt solidifies in a fraction of a second and by limiting the smelt volume per unit of time, spinodal decomposition of the liquid metal film occurs, which is structured by centrifugal forces before solidifying, resulting in large quantities of the micro-metal fibers.

Layers of the fibers with different diameters can be combined to obtain gradient density porous structures, with the number of layers almost unlimited.

![Figure 1: Heat Exchanger Proventics GMBH.[22]](https://www.filtnews.com/wp-content/uploads/IFN_2_2024_crimpedmicrofiberyarns_Fig.-1-Heat-exchanger-225x125.jpg)