Robust, powerful stacked disc cartridges with flexible reuse enable profitable filtration and long-lasting usage through backflushing

Part I of II

New possibilities are emerging in wine filtration. In addition to traditional filtration with plate and frame filters, wine producers are now being offered an alternative in the form of stacked disc cartridges. This technological variant is characterized by the following features and advantages.

In contrast to sheet filtration, the stacked disc cartridge provides a hermetically enclosed system that is drip-free and thus allows for a higher level of hygienic quality. A stacked disc cartridge consists of several filter cells that are stacked one on top of the other and connected to each other. Depending on requirements, a different number of filter cells (ranging from five to 17) can be stacked on top of one another and connected together in a single stacked disc cartridge. This design allows for a compact filtration unit with a significantly smaller mixing zone than conventional plate and frame filter systems, giving more flexibility for different volumes. The smaller mixing zone is particularly advantageous for the filtration of small batches of wine, since it is possible to switch between different batches more quickly. A system with a small mixing zone can therefore process both large and small batches effectively.

When space is limited, stacked disc cartridge housings are the most space-saving option. Depending on the housing type and the connection piping, a housing with up to four stacked disc cartridges (i.e. a maximum filter area of 159.3 ft² or 14.8 m²) can be installed over an area of approx. 23.6 to 27.6 in

(60 to 70 cm) in diameter.

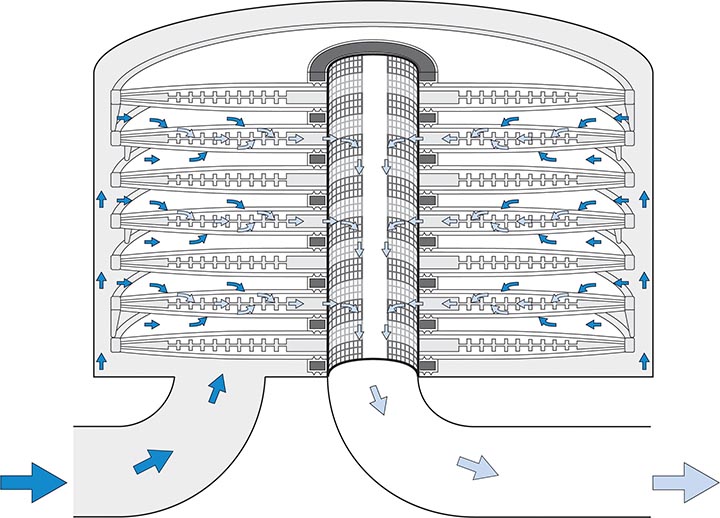

Figure 1 shows the principle of filtration in a stacked disc cartridge. The flow is from the outside to the inside. The wine flows through the depth filter sheets and is filtered. It then enters the filtrate channel inside the cartridge via the drainage plates. The filtered wine flows off from here.

When cleaning, it is recommended to flush and subsequently sterilize the system in the same direction as the flow. It should be noted that most stacked disc cartridges are not backflushable, i.e., all work steps are only possible in the flow direction, as backflushing can be detrimental to the depth filter sheets that are used.

The resulting damage can be either extensive and obvious in nature or consist of micro-cracks that are not visible to the naked eye. In either case, proper filtration is no longer possible, or at least can no longer be guaranteed without the risk of a bypass. This restriction to a single direction of flow affects the service life: Due to the lack of backflushing, the effects of cleaning are limited, which reduces the overall service life of the stacked disc cartridge.

The Alternative: A Longer Service Life Through Backflushing

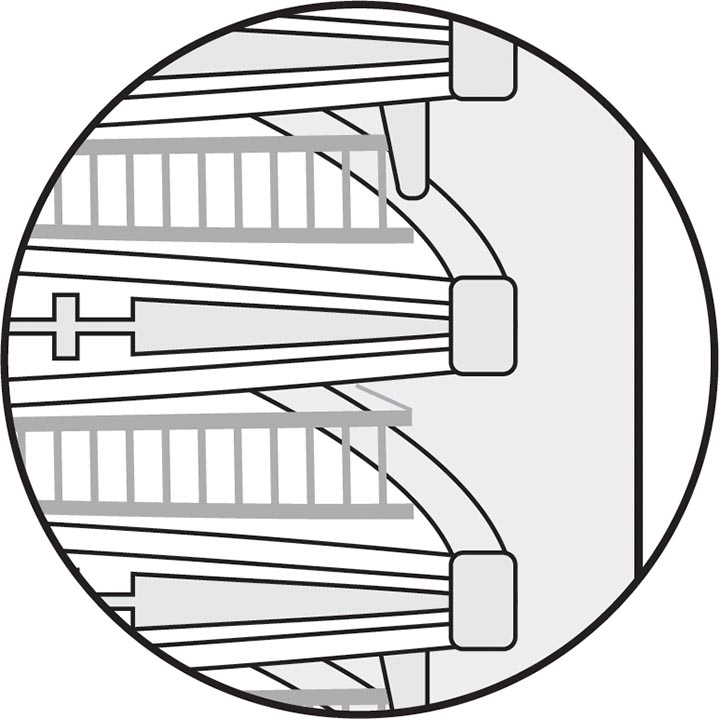

Leading suppliers have therefore further developed their stacked disc cartridges so that backflushing can be carried out. Figures 2 and 3 show the modifications using the example of the Eaton BECODISC® R+ stacked disc cartridge, in which a honeycomb polyester fabric is used between the individual filter cells. The fabric acts like a buffer that keeps the individual filter cells spatially separated from each other during filtration and backflushing and correctly positioned in relation to one other in a stable shape. This design maximizes the stability of the stacked disc cartridge while also

supporting the full use of the filter area.

In addition to improved stability, the special design shown in Figure 3 allows for a longer service life and greater effectiveness with more than 20 backflushing cycles. Despite this modification, the ease of handling has not changed from that of the standard solution, meaning that even existing stacked disc cartridge housings with a commercially available flat adapter connection and stainless steel intermediate plates can still be used. Special backflushing kits are not required.

Putting Backflushable Stacked Disc Cartridges to the Test

In order to verify the longer service life of the backflushable stacked disc cartridge, Eaton has performed an analysis of the flexible filtration of different wines in practical use. In a three-week filtration sequence, during the course of final filtration for microbial removal, an examination was carried out on the filtration parameters of differential pressure and the filter index of different wine batches as well as the backflushing and sterilization intervals.

The BECODISC R+ stacked disc cartridge with BECOPAD® 115 C depth filter sheets was used in the nominal retention range from 0.1 to 0.2 µm, in the 16-inch version, with 16 filter cells and a filter area of 39.8 ft² (3.7 m²). This filter medium complies with the strict standards for microbiological safety and still preserves the ingredients that add value to the product. The flow was 12.28 gal/ft²/h (500 l/m2/h), which corresponds to a flow of 488.7 gal (1,850 l/h) per stacked disc cartridge. The pressure absorption on the inlet and outlet (unfiltrate and filtrate side) was automatically measured by means of a pressure gauge.

The filterability of the wine batches was determined as a filter index with the BECO LiquiControl2TM index measuring device. For this purpose, the storage containers of the measuring device were filled with 0.79 gal (three liters) of each of the different wine batches and filtered via a 0.45 µm flat filter membrane at a constant pressure of 14.5 psi (1.0 bar).

The flushing cycle consisted of ten minutes of cold water, followed by five minutes of hot water and then another five minutes of cold water. The flow during the entire 20-minute backflushing process was 1.5 times the flow during filtration at 18.41 gal/ft²/h (750 l/m2/h). The pressure range during a backflushing cycle was approximately between 8.7 and 11.6 psi (0.6 and 0.8 bar) on the outlet and approximately 0 to 1.5 psi (0 to 0.1 bar) on the inlet.

For sterilization, the stacked disc cartridge was steamed for 20 minutes with filtered saturated steam at 230 °F (110 °C). The steam was supplied in the flow direction at an overpressure of 7.3 psi (0.5 bar). The steam supply was then closed and all valves on the filter housing were opened. The stacked disc cartridge was cooled down with cold water for five minutes.

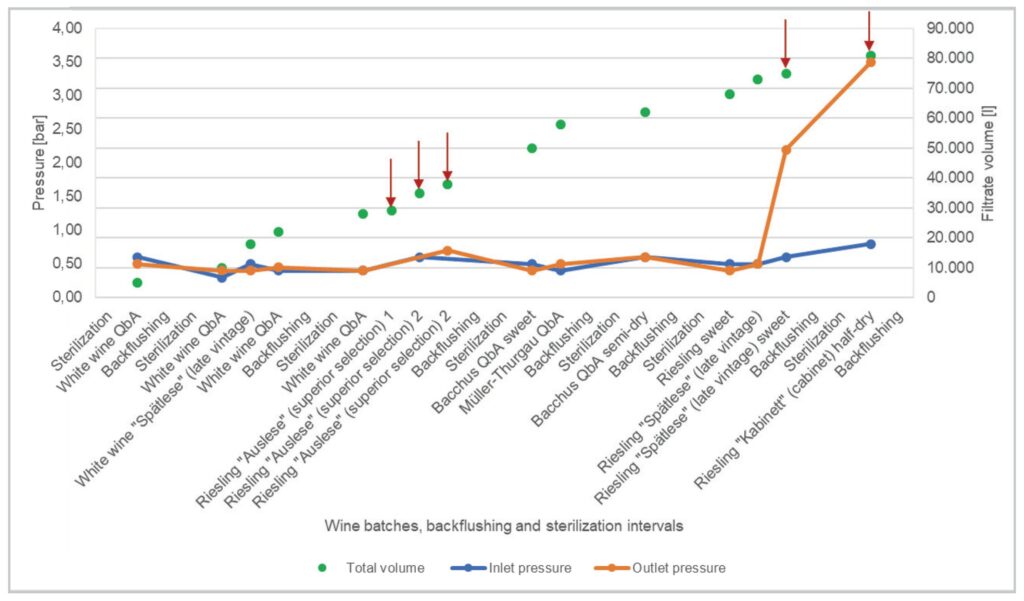

The measurement results of the pressure recording on the inlet and outlet are shown in Figure 4. The differential pressure between the filter inlet and outlet at the beginning and end of each filtration cycle is shown in two graph lines (blue = inlet pressure and orange = outlet pressure). The associated values are entered on the primary left Y-axis (pressure). The filtrate volume can also be viewed. The values for this can be found in the secondary right Y-axis (filtrate volume). The X-axis shows the name of the filtered wine. In addition, the backflushing and sterilization processes are noted on this axis. The red arrows included indicate the difficult to filter wine batches (filter index ≤ 0.4 gal or 1500 ml, see tab. 1).

A total of around 21,398 gal (81,000 liters) were filtered through the backflushable stacked disc cartridge. In this process, 14 different white wine batches of 11 different wine varieties with different quality levels and residual sugar concentrations were filtered and analyzed. The individual batches of wine varied between 264 to 3,170 gal (1,000 and 12,000 liters).

Regardless of the batches of wine used, the results across all wines show that the differential pressure remained constant until shortly before the end of the test. This consistency proves the continuing excellent filtration properties of the backflushable stacked disc cartridge – in this case, through the BECOPAD 115 C premium filter sheets made of high-purity cellulose that were used in the stacked disc cartridge. The pressure at the filter outlet and thus the load for the downstream membrane filter cartridges was consistently low and therefore yielded an optimal filtration result.

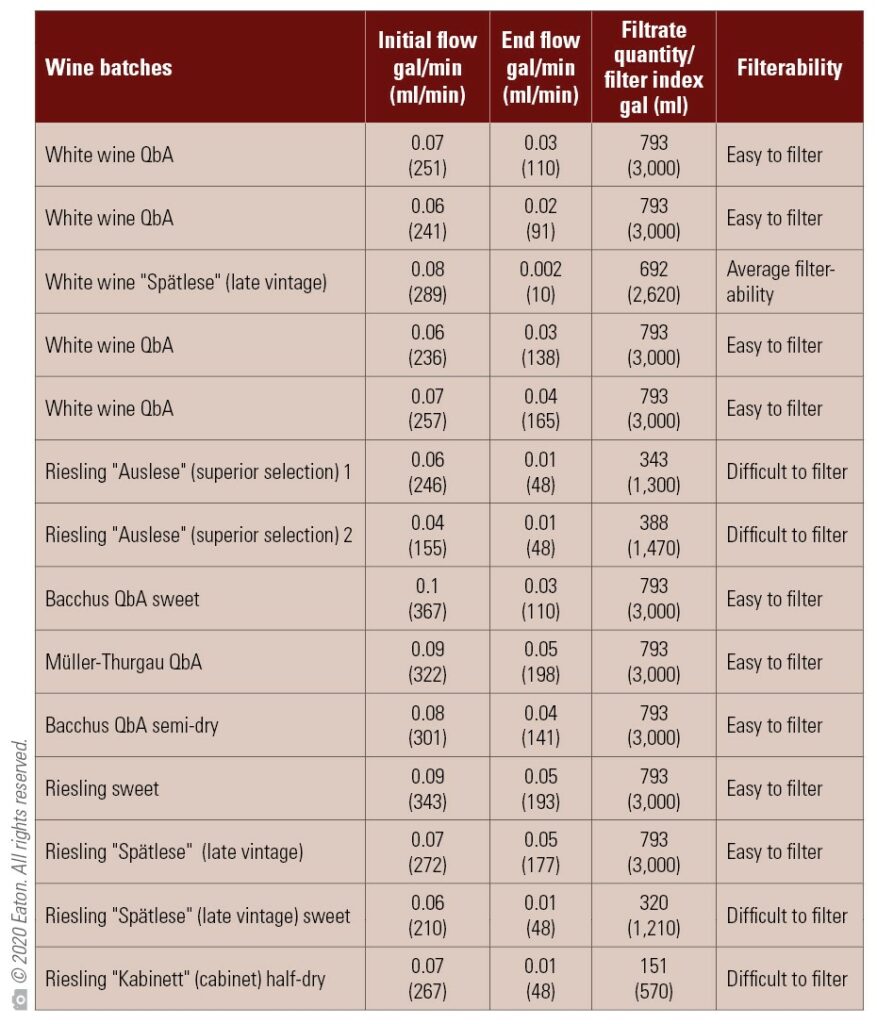

The decisive factor for the evaluation of filtration performance is, above all, the final flow. To determine this, the initial flow is first determined, which specifies the flow volume in milliliters per minute after 0.05 gal (200 ml) of filtration volume. The final flow is then determined accordingly after 0.79 gal (three liters).

In this series of filtration tests, the backflushable stacked disc cartridge has been particularly successful in the case of frequent variety changes. Due to the effective and fast draining of the housing, the mixing volumes were very low. This is particularly important when small quantities of about 264 gal (1,000 liters) are filtered.

The Result: A Longer Service Life in the End Filtration for Microbial Removal

The practical tests with the BECODISC R+ stacked disc cartridge demonstrate a microbiologically stable filtrate during regular regeneration of the backflushable stacked disc cartridge. In total, more than 20 backflushing cycles were achieved, which has extended the service life by about 30% compared to others on the market (data not shown).

The results of the index measurement of all 14 batches of wine in the test are shown in Table 1 (see page 23). Nine batches of wine were classified as easy to filter, one of average filterability and four were difficult.

The four difficult to filter wines were Riesling in the quality stages of “Kabinett” (cabinet), “Spätlese” (late vintage) and “Auslese” (superior selection). Based on the filter index, these wines would not normally be filtered directly via a depth filter sheet for the end filtration for microbial removal. However, in order to analyze the maximum filtration capacity of the backflushable stacked disc cartridge, these wines have also been integrated into the practical test. The results showed that the filter material of the stacked disc cartridge was completely clogged in the case of the wine with the worst filter index (Riesling “Kabinett” half-dry) and could not be regenerated despite backflushing. This result confirms the general statement that the filterability and the corresponding pre-filtration have a fundamental impact on the filtration success, and this is independent of the depth filtration system used.

The practical tests prove the value of backflushable stacked disc cartridges in wine filtration for modern oenology, especially when many different or smaller wine batches are to be flexibly and microbiologically filtered in a reliable manner. The use of BECOPAD depth filter sheets maximizes the stability in the filter material during the backflushing process due to their special cellulose matrix, and simultaneously allows valuable wine ingredients to be preserved. The technological solution of integrating a honeycomb polyester fabric into the spaces between the filter cells stabilizes the pressure conditions in the stacked disc cartridge and protects the depth filter sheets from damage such as tearing or bursting. Backflushing according to instructions is possible without destroying the filter sheet. This increases the filter service life. The cartridge is easy to handle with a space-saving system design, making it an option for winemakers.

Dr. Ilona Schneider, oenologist (Dipl.-Oenologin), Team Leader Product Management Beverage Treatment and R&D, Eaton Technologies GmbH, Langenlonsheim, Germany, IlonaSchneider@wcallaert

![Figure 1: Heat Exchanger Proventics GMBH.[22]](https://www.filtnews.com/wp-content/uploads/IFN_2_2024_crimpedmicrofiberyarns_Fig.-1-Heat-exchanger-225x125.jpg)