Will Raybon is a category manager with Porex, a provider of porous polymer solutions for filtration and a range of other applications. With an array of commercial experience covering global markets in a variety of industries in the manufacturing sector, Will has developed new products for startups and major corporations.

Category Manager for Consumer & Industrial Markets

Porex Filtration

On Oct. 13 at 10 am EST, Will will be leading an IFN Tech Spotlight Webcast on the topic of porous polymer filtration. The following Q&A provides a preview of the material that will be covered during this webinar. You can view an on-demand broadcast of this IFN Tech Spotlight Webcast at bit.ly/ifn-10132021-porexwebinar-ondemand.

IFN: What is a porous polymer, and what are some of the applications for which porous polymers are used?

Will Raybon: Porous polymer solutions create functionality for devices. At Porex, we can utilize a wide variety of polymers to create a porous component. Chances are, you’ve used a Porex porous polymer when coloring with markers or adding fragrance to your home or office. If you’ve ever had a medical procedure, your medical team was utilizing Porex components to prevent infections in the operating room.

IFN: Regarding filtration specifically, how are porous polymers typically being used? Is the use of porous polymers in filtration a relatively new application of the technology, or is it pretty well established?

Will Raybon: Our porous polymers are used to filter target materials out of solutions. Whether its chlorine from water or certain target gases from air, our filtration components can be tuned for various applications. Some filtration applications are well established, but most of what we are working on now is new and cutting edge. We’re always innovating and pushing the limits of filtration capabilities.

IFN: What are some of the application variables that make porous polymers a particularly good fit from a filtration perspective? Are there any common filtration challenges for which porous polymers are particularly well suited to address?

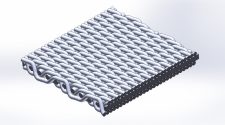

Will Raybon: Our unique ability to create a tortuous pathway through our components makes Porex porous polymers great for filtration. We are able to filter out particles much smaller than our pore size because of this tortuous pathway. Additionally, we are able to make muti-media filtration (think fiber parts combined with sintered parts) that solve multiple filtration challenges with one component.

IFN: How do you see porous polymer technology evolving in the near and long term to meet the needs of users in the filtration category?

Will Raybon: I see Porex porous polymer technology evolving to provide very unique filtration designs that enhance user experiences. We’re able to meet the needs of technical and developmental teams, while focusing on the end user and providing an enhanced experience to them.

IFN: On Oct. 13, you will lead an IFN Tech Spotlight Webcast on porous polymer filtration. What can attendees expect to learn during your presentation? Without revealing too much, what are some of the highlights the folks who attend this session can look forward to?

Will Raybon: We’ll take you inside the science that makes our filtration unique and translate that to how we can make it unique for your part. At Porex, we want to make the world safer, healthier, and more productive—so we’ll make sure you leave that session with confidence that Porex can accomplish our mission with your partnership.

You can view and on-demand broadcast of the IFN Tech Spotlight Webcast, “Using Porous Polymers for Filtration: Don’t Let Poor Design Become a Barrier,” at bit.ly/ifn-10132021-porexwebinar-ondemand.

This content is sponsored by Porex.