Pall Corporation provides critical filtration, separation and purification solutions to meet the demanding needs of a broad spectrum of industrial customers around the globe. We are unified by a singular drive – to solve our customers’ most complex challenges enabling the advancement of health, safety and environmentally responsible technologies.

Our team of experts collaborate with customers in a diverse range of industries including food and beverage, microelectronics, aerospace, fuels, petrochemical, chemical, automotive and power generation. Our industry-leading technologies are at work in countless applications, protecting critical operating assets, improving product quality, safeguarding health, and minimizing emissions and waste.

Pall’s history

Pall was founded in 1946 to develop and market one of Dr. David B. Pall’s early inventions, a porous stainless-steel filter. In the 1950s and 1960s, Pall was a supplier of filters principally for aircraft and chemical process industry use. These products increased aircraft safety and made new chemical innovations possible. Pall underwent an expansion in the 1970s to service electronic, power generation and food processing industries.

Microelectronics

Microelectronics filtration solutions reduce operating and maintenance costs, drastically improve equipment OEE (Overall Equipment Effectiveness) and availability, extend chemical life, reduce defects, and maximize product quality and yields.

Our filtration systems have successfully integrated their proven systems in microelectronics to reduce the cost, increase reliability and maximize the efficiency of electronic manufacturing processes. Solving these challenges directly impacts operation uptime, maintenance frequency, product quality, the life of capital equipment and overall business performance.

Industrial

The industrial marketplace spans a wide array of applications and processes which present a variety of unique challenges. Proper filtration, separation and purification methods are essential in order to achieve the highest productivity and quality. Our products deliver premium filtration and fluid separation performance to ensure high quality results.

Aerospace

We provide filtration, separation, and purification solutions to meet the needs of a broad spectrum of aerospace and defense customers around the globe. Our industry-leading contamination control technologies are at work in countless aerospace and defense applications, protecting critical operating systems, improving product quality, and safeguarding health.

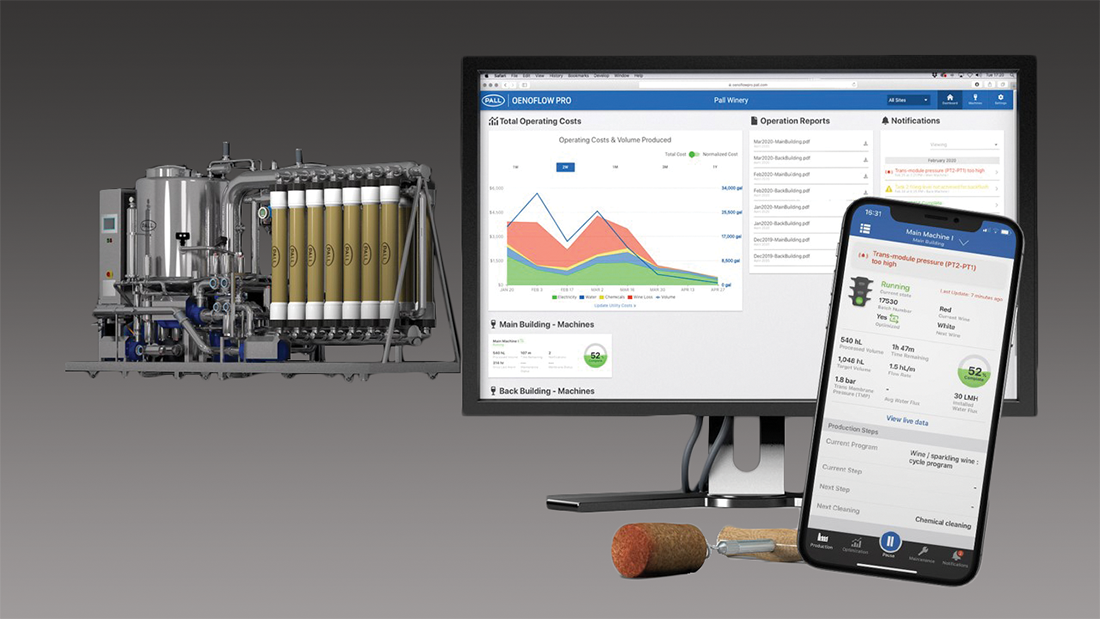

Food & beverage

Product quality is critical for the food and beverage industry, and while the requirements vary across each market segment, the commitment to safety is constant. From producing dairy products to ensuring the integrity of each unique bouquet and flavor intensity in a bottle of wine, everyday Pall is there, helping customers improve product quality, maximize yield, reduce operating costs, and safeguard health.

Where others see something that can’t be done, we jump in fully committed to do it. Discover how we are solving our customers toughest challenges at pall.com.

This content is sponsored by Pall.