In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Matt Migliore at mmigliore@inda.media.

Most recent update: January 18, 2021

Transcend Solutions appoints Carl Hahn to leadership team

Transcend Solutions, a technology leader in the creation and manufacture of custom filtration and separation solutions, has appointed Carl Hahn, Ph.D., to its leadership team. This comes as part of Transcend’s strategy to continue to drive rapid organic growth.

Dr. Hahn is the inventor on eight U.S. patents, a GasPro Americas Advisory Board Member and frequent speaker and consultant on oil and gas process optimization.

Dr. Hahn has a doctorate in Chemistry from Princeton University, and an undergraduate degree from the University of Michigan. He was most recently vice president of Wellstream Processing at NOV, and prior to that he served in a variety of sales and innovation roles with Pentair.

“Carl is well respected in the industry and has been part of many innovative approaches to process optimization through separations,” said Transcend’s director of Applications and Technology, Dave Seeger, Ph.D. “Adding Carl to the Transcend team will supercharge an already phenomenal team of specialists focused on solving complex separations challenges for the process industry.”

Source: trnscnd.com

Dr. Jörg Sievert to retire; Ed Borger takes over as COO for Freudenberg Filtration Technologies

Dr. Jörg Sievert took over as head of the global Filter Division of Freudenberg Nonwovens in 1999. Ten years later, Freudenberg Filtration Technologies became an independent business group and Sievert member of the Management Board. With responsibility for innovation management, health, safety & environment (HSE) and production, he made a significant contribution to the positive strategic and operational development of the company. Sievert was particularly instrumental in the international expansion of the filter business in the Asia-Pacific region, India, Mexico, and South Africa.

He made his mark on the social commitment of Freudenberg Filtration Technologies with the integration of people with disabilities at the Kaiserslautern site and his commitment to the Diakoniewerkstätten Rhein-Neckar (social welfare workshops) based in the Weinheim Industrial Park in Germany.

Ed Borger began his career in the Freudenberg Group in 1999 as Operations Manager at Freudenberg Sealing Technologies in the Netherlands. After holding various management positions in the Netherlands, the UK and Germany, he took on the role of Global Vice President Operations at Freudenberg Filtration Technologies in September 2017.

Source: freudenberg-filter.com

Frost & Sullivan report highlights ‘radical innovations’ in RO desalination technology

Frost & Sullivan’s research report, Radical Innovations in Reverse Osmosis Seawater Desalination, finds that the increase in freshwater demand for human consumption and industrial usage while freshwater resources decline is compelling governments worldwide to investigate innovative technological solutions to access freshwater. As a result, seawater reverse osmosis (SWRO)-based desalination technology has gained industry interest, as it can desalinate seawater in a potentially cost-effective manner. The research highlights the emerging innovations and latest developments in SWRO desalination technologies and the respective technology readiness levels.

“Rising concerns over climate change have set off alarms regarding the future of water supplies, driving the demand for sustainable technology solutions to ensure a reliable freshwater supply,” said Kartikey Shukla, Technical Insights Research Analyst at Frost & Sullivan. “Further, rapid innovation, regulatory amendments, and consumer demand for eco-efficient technology solutions have spurred a structural transformation across the reverse osmosis seawater desalination industry.”

Shukla added, “Technologies such as blockchain are likely to be integrated with reverse osmosis seawater desalination, and this leads residential and commercial users to adopt modular or small-scale desalination plants and use a blockchain-based trading platform to efficiently trade fresh drinkable water amongst the producer and consumer. Going forward, the introduction of blockchain and big data related to small-scale or modular desalination plants can also be useful in making data-driven decisions regarding the need for large-scale reverse osmosis seawater desalination plants.”

According to the report, technology convergence provides an immense landscape of reverse-osmosis seawater desalination opportunities, thereby presenting tremendous growth prospects for market participants, including the following:

- Researchers are encouraged to leverage nanotechnology to develop thin-film membranes that can function at low-pressure conditions to decrease the desalination process energy requirements.

- Vendors can leverage the developments in artificial intelligence (AI) and machine learning technologies to ascertain the composition of materials for the construction of reverse osmosis membranes with desirable properties, such as biofouling resistance and high durability.

- Private participants in the water desalination sector should collaborate with research institutes involved in research and development (R&D) for SWRO desalination.

Radical Innovations in Reverse Osmosis Seawater Desalination is the latest addition to Frost & Sullivan’s Technical Insights research and analyses available through the Frost & Sullivan Leadership Council, which helps organizations identify a continuous flow of growth opportunities to succeed in an unpredictable future.

Source: frost.com

American Filtration and Separations Society launches online Learning Center

The American Filtration and Separations Society (AFS) has now fully launched its new Learning Center, which provides a wealth of technical knowledge for filtration and separations professionals and educational resources which represent the technical knowledge the AFS has assembled over many years.

The AFS Learning Center contains two-hour and four-hour virtual courses on a variety of topics designed to educate both novice and expert filtration professionals. Courses are affordably priced with discounts for AFS members.

Also included are many free one-minute filtration articles (OMFs), such as Water Contamination in Fuel: Cause and Effect, Fundamentals of Gas Filtration: Particle Capture Mechanisms, and Filters and their Efficiency and Life Ratings.

The Learning Center also serves as a repository for past conference proceedings and journal archives and new content will be added regularly.

Visit the Learning Center: https://afss.mclms.net/en/

Source: afssociety.org

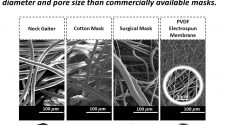

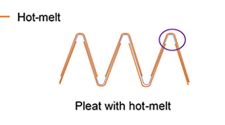

Nonwovens Institute introduces new virtual spunbond and meltblown course

Professionals in the nonwovens/engineered fabrics industry are invited to advance their technical skills in a new 2-day nonwoven short course in the “Virtual Introduction to Spunbond and Meltblown Technology.” This course was developed by North Carolina State University’s Nonwovens Institute and launched by INDA, the Association of Nonwoven Fabrics Industry. The all-virtual course is designed to help manufacturers meet the demand for comprehensive training in the spunbond and meltblown web forming processes used to manufacture respirator/medical face masks, wipes, absorbent hygiene, filtration media, sorbents, and insulation among other end uses.

The course will be held on consecutive Wednesdays, March 24 and March 31, 2021, for a total of 11.5 hours of rigorous training, and available for a two-week review after the course concludes. Production tours of NWI’s spunbond and meltblown lines led by NWI’s renowned team of industry and nonwoven expert instructors are a key component of the virtual agenda.

Expert Instructors for the new course include:

- Pierre D. Grondin, Product Development Director, Nonwovens Institute NWI

- Bryan Haynes, Ph.D., Director of Research and Engineering in Global Nonwovens, Kimberly-Clark Corporation

- Jeffrey Krueger, Ph.D., Raw Material Technology Leader, Kimberly-Clark Global Nonwovens

- Amy Minton, Physical Testing Lab Manager, The Nonwovens Institute NWI

- David Nelson, Assistant Director, Industry Engagement and Education, NWI, 3M, (retired)

- Behnam Pourdeyhimi, Ph.D., William A. Klopman Distinguished Professor of Textile Materials and Associate Dean for Industry Research and Extension, North Carolina State University, and Executive Director, NWI

To register or for more information, visit: https://www.inda.org/education/advanced-training.php

Source: inda.org

* International Filtration News is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).

MBT, Polyguard announce licensing agreement on nano silver antimicrobial tech for facemasks and filter media

MeltBlown Technologies (MBT) of Sandersville, Georgia, has entered an exclusive license agreement with Polyguard Group, to integrate Polyguard’s antimicrobial technology with MBT’s meltblown facemask and filter media.

In 2020, MBT was able to convert its traditional industrial and construction product model into producing meltblown filtration materials for facemasks. MBT was determined to find ways to improve on existing facemask materials and began collaborating with Polyguard Group to create meltblown products with antimicrobial properties.

“Once we met with the team at Polyguard we could see immediately that these guys were innovators. They have created one of the most unique and important antimicrobial technologies the world has ever seen.” said MBT president, Derek Yurgaitis. “I was completely blown away by the nano silver technology, its unique mechanism of action and the potential to be game changing in the fight against infections. Polyguard has already successfully inhibited Corona virus with a 99.15% reduction. We can now begin to imagine materials from HEPA filters to facemasks that prevent microbes from replication on their surfaces.”

Jerry Gaskins, president of Polyguard Group LLC said, “We are extremely excited to join in a license agreement with MeltBlown Technologies to help combat and defeat microbes and viruses such as COVID-19. As a society we need to be ready for the next microbe or virus with pandemic potential. We are also excited to work with MBT in their present business model, creating mold free, fungus free and anti-microbial materials using POLYGUARD which will tremendously enhance their existing business model.”

“One of the challenges for any manufacturer is being able to innovate while executing on its core business efficiently,” said Yurgaitis “Our partnership with Polyguard allows us to focus on our core strengths and continue to build innovative antimicrobial products at a time when the world needs them most.”

Source: meltblowntechnologies.com

AFS FiltCon 2021 announces all-virtual format

Due to ongoing concerns surrounding COVID-19, as well as continued travel restrictions around the world, the American Filtration & Separation Society (AFS) has made the decision to shift AFS FiltCon 2021 to a fully virtual event.

The virtual edition of FiltCon 2021 will consist of two concurrent tracks, taking place over three days, April 19 – 21, 2021. The virtual setting will allow for conference attendees to participate in a total of 36 technical presentations, as all sessions will be available to conference registrants on-demand for two weeks after the live broadcast of presentations. Normally FiltCon provides four concurrent tracks with the ability for conference attendees to participate in a total of 24 technical presentations. By offering two concurrent tracks over three days, the virtual AFS FiltCon 2021 allows conference attendees to participate in a total of 36 technical presentations.

Source: afssociety.org

Flowrox opens subsidiary in Düsseldorf, Germany

Flowrox, a Finland based company specializing in flow control, process automation, environmental and solid-liquid separation technologies, has opened a new subsidiary, Flowrox GmbH in Ratingen, Düsseldorf, Germany.

“For years we have been operating in Central Europe through representatives. Our offering has recently expanded, and we also provide complete industrial solutions. That is why we feel it is crucial to be close to customers in this major market,” said Jukka Koskela, president & CEO of Flowrox. “By setting up a local operation in Central Europe, we can better support our customers and representatives with local projects, sales and services.”

As part of this expansion, Dirk Otto has joined Flowrox as managing and sales director, Central Europe. Mr. Otto has a strong background in process technology and solid-liquid separation. Before joining Flowrox, he has worked with some leading companies from the field such as Larox, Clear Edge Filtration and Ipsen International.

With this new branch, Flowrox has 10 subsidiaries located in Australia, Chile, China, Finland, Germany, Peru, Russia, South Africa, Sweden and the United States, as well as more than 230 sales representatives in over 80 countries.

Source: flowrox.com

Mann+Hummel celebrates 80th anniversary

Filtration specialist Mann+Hummel celebrates its 80th anniversary in 2021. Since its founding in 1941, the family owned company has developed into a leading filtration expert, providing employment for around 22,000 people at more than 80 locations. “We owe our continued success mainly to our reliability, continuity and identification as a family owned company. As Chairman of the Supervisory Board and grandson of one of the founders, Adolf Mann, I am very proud to be able to continue the legacy that he and Dr. Erich Hummel started in 1941, along with dedicated employees,” said Thomas Fischer, Chairman of the Supervisory Board.

With the ongoing COVID-19 pandemic, festivities marking the event will be on an individual and partly digital basis at the Mann+Hummel sites worldwide. The company has also designed a brochure documenting the milestones in the company’s history.

When company founders Adolf Mann and Dr. Erich Hummel established the “Filterwerk Mann + Hummel” in 1941, both could already look back on successful careers. One was a mathematics teacher, the other a lawyer, and in the 1920s they had both made careers at the traditional Stuttgart textile manufacturer Bleyle. In the 1940s, the dedicated businessmen took a brave step to enter filter production in order to save the jobs of their employees: Taking over the production of oil and air filters from the Stuttgart-based piston manufacturer Mahle, initially in contract manufacturing and later completely, they founded the filter plant in 1941. Thus Mann+Hummel was born. A characteristic feature of the founders’ ambitions was the intensive research and testing activity that began immediately after the purchase. With foresight, Adolf Mann wrote in 1942 in the company newspaper “Der Herold” that the filter product had a future in a field “in which there will be no lack of tasks in war and in peace.”

Adolf Mann was to be proven right with his statement. In 2019, almost eight decades after its founding, the globally active filtration specialist announced the highest sales revenue in the company’s history at EUR 4.2 billion – despite increasingly challenging conditions resulting from, among other things, mobility change, environmental and climate awareness, digitalization and political shifts. “In the course of my 20 years with the company, I have become familiar with all areas of Mann+Hummel. What impresses me most are the people who, even under challenging circumstances, work every day with great commitment to our common goals,” said Kurk Wilks, Mann+Hummel’s president and CEO.

With the development of antiviral air purifiers, Mann+Hummel is currently helping to contain the spread of the coronavirus with its filtration technology. The devices filter the SARS-CoV-2 virus, flu and cold viruses, as well as free allergens from the air. “We see our core competence of filtration as a key technology that can make a lasting and decisive contribution to cleaner mobility, cleaner water and cleaner air. The primary goal here is to secure the company’s future viability while at the same time expanding our market leadership in filtration,” explained Fischer.

With various acquisitions such as Hardy Filtration (2019), a Canadian air filtration company, and the takeover of parts of Seccua Holding AG (2019), which specializes in the development and production of ultrafiltration systems for drinking water treatment, as well as the acquisition of helsa Functional Coating last year, through which the portfolio was supplemented mainly in molecular filtration and elastomer and activated carbon technology for special industrial applications, the company is expanding its expertise in growth markets worldwide.

Source: mann-hummel.com

Cerahelix appoints Will Sarni and Martin Grohman to board of directors

Cerahelix, a manufacturer of ceramic nanofiltration membrane products, has added two members to its board of directors, Will Sarni, an internationally recognized thought leader on water strategy and innovation, and Martin Grohman, executive director of the Environmental & Energy Technology Council of Maine (E2Tech).

“We are indeed fortunate to welcome Will and Martin to our Board of Directors. Each brings outstanding experience and insights to Cerahelix as we continue to advance commercialization of our breakthrough ceramic nanofiltration membranes, which are being used for filtration and separation applications in industrial water reuse, and in such industries as food & beverage and biopharmaceuticals & nutraceuticals,” said Bill Paulus, chief executive officer of Cerahelix.

Sarni is the founder and chief executive officer of Water Foundry, an advisor to global public and private sector enterprises, non-governmental organizations and technology providers in solving water-related challenges. Sarni has been a sustainability and water strategy advisor to multinationals, water technology companies, investors and non-governmental organizations. Prior to establishing Water Foundry, Mr. Sarni was a managing director at Deloitte Consulting and founded and led the water strategy practice. Earlier, he was the Founder and CEO of DOMANI, a sustainability strategy firm. He has written numerous books and articles and continues to present on such subjects as the value of water, innovations in digital water technology, the circular economy, and the energy-water-food nexus. He holds both master’s and bachelor’s degrees in Earth and Environmental Sciences from Queens College, CUNY, New York.

Grohman is highly respected for his business acumen and longtime focus on sustainability that precedes his leadership role at E2Tech, Maine’s foremost energy, environmental and clean technology business and economic development organization. He is a former member of the Maine State House of Representatives, where he served on the Energy, Utilities and Technology Committee. Grohman co-founded DuraLife Decking, a composite decking manufacturing company that was acquired by GAF, North America’s largest roofing manufacturer. Following the acquisition, he served as GAF’s Director of Sustainability, developing initiatives such as roofing recycling and the company’s Zero-Waste-to-Landfill effort, as well as building networks with national organizations such as the US Green Building Council. Mr. Grohman holds a degree in Chemical Engineering from Rensselaer Polytechnic Institute.

Source: cerahelix.com

SUEZ completes acquisition of LANXESS RO membrane product line

SUEZ has finalized the purchase of the Reverse Osmosis (RO) membrane product line from specialty chemical company LANXESS. Integrating the RO membranes into the SUEZ existing product portfolio expands and complements SUEZ’s reach into the industrial water market and provides a strong foundation for growth in adjacent sectors, according to the company.

The purchase falls in line with SUEZ’s strategy to grow and invest in the industrial water market.

“This acquisition allows us to meet a rapidly growing need for brackish water RO membranes with a product that complements our existing technology portfolio,” said Yuvbir Singh, CEO of SUEZ’s Water Technologies & Solutions business unit. “I’d like to welcome the employees at the Bitterfeld production facility to the SUEZ family, and express our commitment to our new channel and distribution partners. We are looking forward to working with them and growing in new ways around the world.”

The purchase of LANXESS’ RO product line includes the RO membranes product line and production facility located in Bitterfeld, Germany. With the purchase now complete, SUEZ will integrate the membranes into its full solutions portfolio to meet broader and emerging water treatment needs, while adding additional international RO membrane production capabilities and capacity to meet growing global demand.

Source: suezwatertechnologies.com

Researchers identify nanofiltration process to produce more clean water with less energy

Producing clean water at a lower cost could be on the horizon after researchers from The University of Texas at Austin and Penn State solved a complex problem that had baffled scientists for decades, until now.

Desalination membranes remove salt and other chemicals from water, a process critical to the health of society, cleaning billions of gallons of water for agriculture, energy production and drinking. The idea seems simple — push salty water through and clean water comes out the other side — but it contains complex intricacies that scientists are still trying to understand.

The research team, in partnership with DuPont Water Solutions, solved an important aspect of this mystery, opening the door to reduce costs of clean water production. The researchers determined desalination membranes are inconsistent in density and mass distribution, which can hold back their performance. Uniform density at the nanoscale is the key to increasing how much clean water these membranes can create.

“Reverse osmosis membranes are widely used for cleaning water, but there’s still a lot we don’t know about them,” said Manish Kumar, an associate professor in the Department of Civil, Architectural and Environmental Engineering at UT Austin, who co-led the research. “We couldn’t really say how water moves through them, so all the improvements over the past 40 years have essentially been done in the dark.”

The findings were published in Science.

The paper documents a 30%-40% increase in efficiency in the membranes tested, meaning they can clean more water while using significantly less energy. That could lead to increased access to clean water and lower water bills for individual homes and large users alike.

Read the full story: https://news.utexas.edu/2020/12/31/desalination-breakthrough-could-lead-to-cheaper-water-filtration/

Source: https://news.utexas.edu/

Pentair acquires Rocean, expands residential and commercial water treatment footprint

Pentair plc has completed its acquisition of Be the Change Labs, Inc., d/b/a Rocean, a provider of technology for smart, sustainable water solutions. Its smart filtration devices provide countertop filtration solutions with the aim of reducing single-use plastic bottles in homes and businesses.

“This acquisition further advances our strategy to expand our core water treatment products in the residential and commercial water business and allows us to continue serving customers in new ways, while also supporting our efforts to create a more sustainable future,” said Mario D’Ovidio, Executive Vice President and President, Pentair Consumer Solutions. “Together, we can connect people to great water in the home, on the go and around the world.”

The Rocean One was recently recognized by TIME magazine as a “Special Mention” for its list of “Best Inventions of 2020.”

Source: pentair.com

Evoqua Acquires Ultrapure’s Industrial Water Business in Houston and Dallas

Evoqua Water Technologies , an industry leader in mission-critical water treatment solutions, today announced it has acquired the industrial water business of privately-held Ultrapure & Industrial Services, LLC, a subsidiary of Driessen Water, Inc. Ultrapure’s industrial operations are based out of Houston and Dallas, Texas. This acquisition will further strengthen Evoqua’s service capabilities in the Houston and Dallas markets and the surrounding regions. Terms of the deal were not disclosed.

Ultrapure’s Texas-based operations focus on water purification services and equipment, serving the healthcare, laboratory, power, microelectronics, food and beverage, oil and gas, commercial, and manufacturing markets. Ultrapure provides its customers with a variety of water treatment products and services, including service deionization, reverse osmosis, UV, and ozonation.

“For over 20 years, Ultrapure’s industrial operations has built a reputation as a trusted partner, providing reliable water solutions and services to their broad customer portfolio,” said Evoqua Chief Executive Officer Ron Keating. “We are delighted to welcome the Houston and Dallas Ultrapure team to the Evoqua family.”

Source: evoqua.com