In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Matt Migliore at mmigliore@inda.media.

Most recent update: February 28, 2022

Registration now open for NAFA 2022 Technical Seminar

Registration for the National Air Filtration Association’s annual Technical Seminar, April 5-7 in Louisville, Kentucky, is now open. The event is expected to attract more than 200 professionals from the air filtration industry, who will meet to build connections, share best practices and learn from an expert lineup of speakers.

The 2022 NAFA Technical Seminar Keynote Speaker is Shelly Miller, Ph.D., professor in the Environmental Engineering Program at the University of Colorado Boulder. Dr. Miller will be presenting on how filtration and other tools can be used to further decrease the spread of COVID-19. As the COVID-19 pandemic moves across the world, scientists like Dr. Miller have been working to better understand how the SARS-CoV-2 virus is transmitted, the details of the symptoms and illness, and how to stop the spread of the virus. Her presentation, “Helping to Save the World from COVID-19: why an urban air pollution engineer got involved, and what she did to makes things better,” will outline her research into how air filtration can be used in the battle against COVID-19.

To view the full conference program, visit events.nafahq.org/program/.

To register for the NAFA Technical Seminar, visit events.nafahq.org/register/.

Source: nafahq.org

Camfil expands Malaysian manufacturing capacity to meet global demand

Land acquired in Malaysia is the base for a new plant expansion for Camfil Malaysia (Ipoh). This is one of the group’s latest investments to increase its capacity and manufacturing footprint to meet demand in air filter products and services in the Asia Pacific region, as well as globally. The total land size of the plant will increase to 759,000 square feet, and it will be operational by Q4 in 2022.

The plant expansion will be adjacent to an existing Camfil plant, and it will include a hi-tech R&D facility, as well as a state-of-the-art high-efficiency particulate air (HEPA) filter, turbomachinery, and molecular filter manufacturing operation. The plant will continue to produce more energy-saving air filters and provide clean air solutions aligned to the United Nations Sustainable Development Goals (UNSDG).

The group has pledged its company and manufacturing strategy to support the UNSDG, ensuring a meaningful contribution to sustainability globally. The four goals that have been identified as the most relevant to its business are goal 3, good health and wellbeing; goal 8, decent work and economic growth; goal 11, sustainable cities and communities; and goal 12, responsible consumption and production.

This new integrated facility will run in multiple production lines, including HEPA filter and molecular contamination control filters. Together, with the plant expansion, deployment of modern manufacturing techniques, and many other sustainable features, Camfil will be able to cater to the increased demand for air filters in the APAC region. “

The new expansion will give us additional warehouse space, I foresee that we will have a reduction of approximately 50% in lead time” said Karunagaran Krishnan, Camfil Malaysia Head of Plant & VP Supply Chain (APAC).

Source: camfil.com

Neenah announces 25M euro investment in meltblown line for its filtration manufacturing facility in Germany

Neenah, Inc., a global manufacturer of specialty materials for filtration media, specialty coatings, engineered materials, and imaging & packaging, announced a 25 million euro investment in new meltblown capacity in its German filtration facility. The new meltblown line is expected to be online in mid-2024.

Neenah is committed to accelerating growth in life science and industrial filtration markets, and this investment reflects that aim. Neenah’s portfolio of meltblown products is designed to promote higher filtration efficiency and lower energy usage, with the company’s electrostatically charged NeenahPure media solutions supporting HVAC, air pollution control, and air purification systems, delivering market leading efficiencies >99.9%.

“Clean air and water are critical to our communities and environment. Meltblown technology effectively removes harmful particles from the air we breathe and the water we drink. This new meltblown line intensifies our innovation efforts and allows us to continue to grow with our customers,” said Neenah president and CEO, Julie Schertell.

Source: neenah.com

IDA World Congress extends abstract submission deadline for several tracks

Due to an overwhelming number of requests from authors, the International Desalination Association announced an extension to its March 15th deadline for abstract submissions for the upcoming 2022 World Congress, Oct. 9-13 in Sydney Australia. Abstracts will continue to be accepted in the following categories:

- Water Reuse, Potable and Non-Potable Including Public Outreach

- Industrial Water & Wastewater Treatment

- Membrane Science

- Environment and Sustainability

- Governance, Finance and Project Delivery

To submit abstracts, visit wc.idadesal.org.

The IDA World Congress is a five-day event, with a week of learning, sharing ideas, developing business, and networking to advance the solutions that will secure water for all.

Registration for the 2022 World Congress is currently open for all IDA members and non-members. Registration includes:

- Access to the four-day, four-track peer-reviewed Technical Program

- Access to four-day exhibition

- Daily lunch and refreshment breaks

- Networking events, including welcome reception, opening ceremony, gala dinner with Industry & Sustainability award ceremony, traditional closing luncheon & awards ceremony

- Congress proceedings

- Plant tours

Registration rates and options can be found at wc.idadesal.org.

Source: idadesal.org

Andritz to supply four needlepunch lines to Yanpai Filtration; startup expected between Q3 2022 and Q3 2023

Andritz announced that it will deliver customized needlepunch lines for production of needlepunch filter felts at Yanpai Filtration in Zhejiang Province, China. The lines are expected to enable Yanpai to achieve state-of-the-art technical characteristics in terms of product quality and line performance. The drylaid web-forming equipment (cards and crosslappers) will be manufactured at the Andritz Wuxi facility, including 8 PRO 25-80 aXcess profile crosslappers for controlled web weight evenness. An additional 16 eXcelle needlelooms will be supplied by Andritz Asselin-Thibeau in France.

Start-up of the lines is planned from the third quarter of 2022 to the third quarter of 2023.

Yanpai is one of the leading Chinese producers of nonwoven filters for dust and air treatment and for woven filter fabrics used in solid/liquid separation. Established in 1990, Yanpai was at the forefront in the development of new industrial filtration fabrics. Today, Yanpai has facilities in China and the United States.

Source: andritz.com

Micronics Engineered Filtration Group acquires National Filter Media

Micronics Engineered Filtration Group, a family of filtration brands serving the global market, announced the acquisition of National Filter Media (NFM), a global provider of baghouse, pressure filtration and vacuum filters, based in Salt Lake City, Utah, USA.

The acquisition of National Filter Media significantly expands Micronics’ portfolio of engineered filtration solutions for advanced filtration. The addition of NFM adds filter media options to the Micronics portfolio, including belt press dewatering belts, pressure leaf filter media, horizontal vacuum belt filter media, rotary vacuum drum filter media, rotary vacuum belt filter media, rotary vacuum disc filter media, and vacuum pan/table filter media.

“I am excited to welcome NFM and FilterFab to the Micronics family of trusted wet and dry filtration brands. I am very much looking forward to working with our talented new NFM and FilterFab teammates as we bring our combined talents and capabilities to our valued global customers,” said Chris Cummins, president and CEO of the Micronics Engineered Filtration Group.

Mr. Cummins will head up the newly combined company.

With the addition of National Filter Media, The Micronics Engineered Filtration Group is now comprised of wet and dry filtration brand names, including Micronics, Southern Filter Media (SFM), C.P. Environmental (CPE), United Process Control (UPC), AeroPulse, National Filter Media (NFM), FilterFab, Midwesco Filter Resources (Midwesco) and Fabricated Filters.

Source: micronicsinc.com

INDA names Jen Greenamoyer as its new director of government affairs

INDA, The Association of the Nonwoven Fabrics Industry, has named Jennifer “Jen” Greenamoyer as its new director of government affairs with the aim of raising the association’s profile in Washington, D.C. She brings 25 years of experience at associations, the U.S. Environmental Protection Agency (EPA) and on Capitol Hill to the position.

Most recently, Greenamoyer served as senior government relations liaison and the principal lobbyist at the American Institute of Physics (AIP) for 15 years, where she represented the association to Congress and lobbied for appropriations. She has strong expertise in science policy and education that is expected to enhance her role as an information resource for INDA members, staff and others on government-related matters affecting the nonwovens industry.

At INDA, Greenamoyer will serve as the liaison between the nonwovens industry and government legislative and regulatory bodies by preparing formal submissions to the federal government articulating industry positions, and representing INDA on the Industry Trade Advisory Committee for Textiles and Apparel (ITAC 13), among other responsibilities.

“With her excellent experience and capabilities, Jen will be a great asset to INDA’s members by advocating on issues that directly impact our members and raising INDA’s profile with policymakers and government and business organizations in Washington, D.C.,” said Dave Rousse, INDA president. “She will play a critical role in supporting INDA’s new strategic plan that includes advocating for the nonwovens industry in public policy forums and achieving industry relevance among key stakeholders.”

“I am excited about this new opportunity to join INDA to be part of bolder and more strategic advocacy efforts for the nonwovens industry,” Greenamoyer said.

Greenamoyer holds master’s degrees in Marine Affairs and Oceanography, both from the University of Rhode Island, and a Bachelor’s in degree Marine Science from Stockton College of New Jersey. She begins her role Feb. 22 and looks forward and will be meeting industry professionals at INDA’s upcoming IDEA and FiltXPO events, March 28-31, at the Miami Beach Convention Center. Greenamoyer succeeds Jessica Franken in this role.

Source: inda.org

Ahlstrom-Munksjö previews strong YOY sales and EBITDA increases; announces investor agreement with plans for a strategic acquisition

Ahlstrom-Munksjö Holding announced that its 2021 pro forma net sales increased to EUR 3,076.6 million (from 2,683.3 in 2020) and pro forma comparable EBITDA to EUR 398.3 million (from 334.2 in 2020).

Ahlstrom-Munksjö Holding further estimates that reported net sales were EUR 2,814.2 million and operating result EUR 72.3 million in 2021.

Ahlstrom-Munksjö’s parent company Ahlstrom-Munksjö Holding 3 Oy will publish its full year 2021 results in March.

Ahlstrom-Munksjö Holding 3 Oy also announced that it has entered into an agreement with certain investors pursuant to which it will raise EUR 60 million as an add-on to its existing Senior Term Loan Facility maturing in February 2028.

The proceeds from this transaction are planned to be used for the general corporate purposes of the group, including a targeted strategic acquisition.

Source: ahlstrom-munksjo.com

Xylem’s Global Student Innovation Challenge targets novel solutions for water access and resilience

Xylem announced the Global Student Innovation Challenge for secondary and tertiary students worldwide to propose novel solutions for expanding water access and resilience. Registration for the virtual challenge, which forms part of the company’s dedicated student development program, Xylem Ignite, closes on March 7, 2022. Students will compete for eight cash prizes from a $20,000 prize pool.

Over the course of eight weeks, students will submit solutions to one of four challenge statements, with access to masterclasses and support from mentors across the water industry. The challenges include: Solving Water with Alternative Sensing Technologies, Smart Floating City Master Plan, Raising Awareness for Water Equity and Kickstarting Water’s Race to Net Zero. The participants will work in teams of up to five students, for the chance to win prizes for the top secondary and tertiary projects.

“It is a critical moment for water, and also one that presents incredible new opportunities,” said Patrick Decker, Xylem’s chief executive officer. “Now more than ever, a generation of engaged, passionate and creative young people are speaking up and taking action – advocating and innovating for a more sustainable world. Xylem Ignite is our global youth program to build a strong network of passionate young leaders and empower them to drive real solutions to water issues. Building on the success of our inaugural 2021 Global Student Innovation Challenge, we’re now calling on those who are passionate about solving water to join us in 2022 and help solve the world’s greatest water challenges.”

The global program is designed to enable participation from different countries and time zones, and to accommodate school schedules. Students aged 13-25, and of all experience levels, are encouraged to participate. Individual registration for the innovation challenge closes at 2:59am, US Eastern Time, on March 7, 2022.

Xylem Ignite was conceived in mid-2020 by a team of young professionals in Xylem, as a platform to engage the passion and creativity of students around the world. The investments are targeted to give interested students access to the resources needed to develop their ideas and innovations.

The Xylem Ignite program engages students to:

- Prioritize the need for the next generation of water professionals across several career fields and all relevant industries.

- Accelerate innovation through hackathon events, critical problem-solving challenges, and incubator initiatives.

- Advance water sustainability education with training, masterclasses and mentorship from Xylem leaders and industry experts.

- Give back to the community with water-oriented volunteerism.

For more information on the Global Student Innovation Challenge, visit innovationchallenge.xylem.com.

Source: xylem.com

Sartorius completes acquisition of Novasep’s chromatography division; updates 2022 sales forecast

Sartorius, through its subgroup Sartorius Stedim Biotech, closed the acquisition of the Novasep’s chromatography division earlier this month, following approval by the U.S. Federal Trade Commission. The transaction had previously been agreed upon in 2021, with the acquired portfolio bringing chromatography systems primarily suited for smaller biomolecules, such as oligonucleotides, peptides, and insulin, as well as systems for continuous manufacturing of biologics. Since 2018, Novasep and Sartorius have also been jointly developing optimized systems for a membrane-based chromatography technology.

The acquired business generated sales of around 40 million euros in 2020 at a double-digit profit margin; final figures for 2021 are not yet available. The majority of the approximately 100 employees working in Novasep’s chromatography business are at the Pompey site in eastern France, with some working in the U.S., China and India.

The acquisition is expected to generate additional non-organic sales revenue growth of around 1 percentage point in 2022. As such, Sartorius has updated its sales revenue forecast for the current year as follows: Consolidated sales revenue is now expected to increase by about 15% to 19% (previously about 14% to 18%), with non-organic growth from acquisitions projected to contribute about 2 percentage points (previously about 1 percentage point). The company’s underlying EBITDA margin remains forecasted at about 34% this year.

For the Bioprocess Solutions Division, the company now forecasts sales revenue growth of about 17% to 21% for 2022 (previously about 16% to 20%), with non-organic growth from acquisitions contributing around 2 percentage points (previously around 1 percentage point). The division’s underlying EBITDA margin is still expected to be around 36%. The 2022 forecasts for the Lab Products & Services Division remain unchanged: Accordingly, the company continues to project sales revenue growth of about 6% to 10%, including a non-organic growth contribution from acquisitions of around 1 percentage point, and an underlying EBITDA margin of around 26% for the division.

All forecasts are based on constant currencies.

Source: sartorius.com

Xylem appoints new managing director for its India business unit

Xylem Inc., a global water technology company, appointed Yatin Tayalia as managing director of Xylem India. The current managing director, Nitin Bhate, will be taking on a new role as the global director and general manager of Xylem Custom Pumps.

Tayalia will report to Franz Cerwinka, president for emerging markets for Xylem, and he will be based in Bangalore, India.

“Yatin brings extensive experience in water management and advanced technologies in water, aligned with our continuing development and growth in India,” said Cerwinka. “He is recognized as a thought leader in both the sector and region for water management, water reuse and driving advanced technologies in water and wastewater treatment.”

A veteran of the industry, Tayalia has co-authored more than 10 patents and published multiple technical and policy journal articles. He has served as senior vice president and business leader for South Asia at Suez Water Technologies and Solutions and has more than 25 years of experience in water, chemicals and computational analysis industries across Asia, with diversified leadership experience in business, sales, commercial, product and technology management. Tayalia has an integrated Bachelors and Masters of Technology in Chemical Engineering from the Indian Institute of Technology, Mumbai.

Source: xylem.com

NX Filtration reports 2021 financials; showing strong YOY revenue gains

NX Filtration N.V., provider of direct nanofiltration (dNF) technology for water treatment, reported its consolidated financial statements for 2021, with total revenues of €4.1M, an increase of 281% compared to 2020, outperforming the €3.7M outlook reported at its IPO and half-year results.

An increase in the number of pilot and full-scale projects, a contract with Hydranautics to produce and supply HYDRAcap ultrafiltration (UF) modules (with a gradual ramp-up in volumes during 2021), the expansion of its sales force to new countries (U.S., Canada, India, Singapore and UAE), and a growing number of repeat projects from OEM relationships were cited as key drivers of growth.

Strongest growth was reported in the Sustainable Industrial Water business line, with revenues from the sale of goods of €2,072k in 2021 (€771k in H1 2021 and €1,301k in H2 2021), a growth of 468% compared to €365k in 2020. NX Filtration benefitted from the pilots it had initiated since mid-2020 and the relatively short lead times from pilots to full-scale projects. Strong traction was seen with customers in, amongst others, the food & beverage, textile and paper industries looking to reduce their water footprint and optimize their water systems.

In the Clean Municipal Water business line, revenues from the sale of goods in 2021 were €1,101k (€317k in H1 2021 and €784k in H2 2021), a growth of 260% compared to €306k in 2020. This growth was primarily driven by full-scale projects in Asia, whereas the focus in Europe and North America has been on realizing pilots with leading players, with visibility on future large projects.

EBITDA loss (excluding costs related to the IPO) was €3,738k in 2021 compared to a loss of €1,972k in 2020. EBITDA loss including costs related to the IPO was €13,323k in 2021. Net loss (excluding costs related to the IPO and corresponding tax effect of €2,334k) amounted to €4,103k compared to a net loss of €2,092k in 2020. Net loss including costs related to the IPO was €11,354k in 2021.

Going forward, NX Filtration expects further ramp-up of its commercial roll-out program, enabled by a growing fleet of pilot systems (from 18 at the end of 2020, to 85 at the end of 2021 and anticipated more than 140 at the end of 2022) and an increase in the number of pilot engineers.

With the addition of a second spinning line for the production of its dNF membranes, further growth opportunities and production efficiencies are expected. In 2022, NX Filtration will also take steps in the development of a new large-scale production plant, with construction expected to start in the second half of the year. The company also expects to expand international sales, pilot engineering, R&D and production personnel.

Source: nxfiltration.com

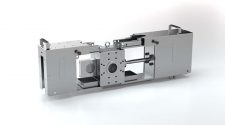

BB Engineering GmbH delivers melt filter for PET recycling to Indorama Polyester

BB Engineering GmbH (Germany) reports the deliver of a melt filter for recycling PET flakes to polyester manufacturer Indorama Polyester Industries (Thailand). Indorama will use the type NSF38 filter in its recently assembled recycling system to produce rPET granulate from flake PET bottle waste.

The NSF38 filter enables continual filtering – in other words, the system switches from one filter to the other during the process without the need for conversion shut-downs. The filter allows the processing of consumer waste for example, in the form of shredded PET bottles into new, high-quality rPET granulate. This granulate is subsequently processed into manmade fibers in spinning systems.

The NSF38 is a switchable filter with a filter surface area of approx. 16 m2 on each side, with throughputs of between 1,000 and 1,900 kg/h. The filter inserts each contain 19 pleated filter candles (60 x 1,000mm Ø). The filter medium comprises a sintered metal fiber nonwoven with a filtration fineness of 25 μm. This ensures that the melt remains free of contaminants and gel particles, which in turn enables the production of high-quality end products, according to BB Engineering.

Source: bbengrs.com

Nelson Labs announces verification program for facemasks and respirators

Nelson Labs, a leading global provider of laboratory testing and advisory services, has launched the Nelson Labs Mark, a verification program for product testing that authenticates test reports and provides data on product performance. The new offering is designed to empower consumers to make informed decisions when purchasing facemasks and respirators, as well as providing credible manufacturers with the means to differentiate their products from others on the market.

Amidst a rise in fraudulent products and the ongoing COVID-19 pandemic, Nelson Labs anticipates the program will become a valuable tool for hospitals, municipalities, and commercial buyers, along with private consumers. According to Nelson Labs, the Mark will begin with testing verification for masks and respirators but will expand to other products as the market requires.

“With varying regulatory requirements and amended qualifications during COVID-19, it is difficult for today’s consumers to discern legitimate products from those that have not been adequately tested,” said Jeffery R. Nelson, chairman, Nelson Labs. “The Nelson Labs Mark addresses this critical need for increased transparency by providing objective, verifiable performance data from our world-class laboratories.”

To further increase consumer confidence, the Nelson Labs Mark includes two-factor authentication for consumers to easily confirm the legitimacy of a product’s testing. The company will allow manufacturers participating in the Nelson Labs Mark program, whose products have undergone testing at Nelson Labs, to use the Nelson Labs Tested™ or Nelson Labs Verified™ mark on applicable product packaging and marketing, along with a corresponding web listing that includes detailed test reports outlining the performance of that product.

For more details on the program, visit nelsonlabs.com/get-verified.

Source: nelsonlabs.com

Mitsui Chemicals expands meltblown capacity; filtration a key target

Mitsui Chemicals announced plans to expand its production facilities for meltblown nonwovens at its subsidiary Sunrex Industry Co. Ltd. The move comes in an effort to respond to growing demand for industrial-use meltblown nonwovens, and it will drive a 30% increase in the company’s overall production capacity for meltblown nonwovens.

As part of its new VISION 2030 Long-Term Business Plan, Mitsui Chemicals will be positioning nonwovens as a growth business under its Life & Healthcare Solutions unit. Mitsui Chemicals is looking to supply nonwovens not only as sanitary materials for applications such as disposable diapers, but also as industrial materials for a variety of applications.

Products targeted toward this end will include TAFNEL, which can be used as an oil-adsorbing material, a structural material for automotive seats and a civil engineering material; SYNTEX, a structural material for filters and masks; and other such high-quality nonwovens. In particular, SYNTEX nano – a brand consisting of superfine fibers – is expected to meet with use in products such as highly advanced precision filters.

Mitsui Chemicals plans to further bolster and grow its nonwovens business going forward, with the newly announced facility expansion coming as one such move.

Source: jp.mitsuichemicals.com

Evonik touts more than 1,000 reference plants worldwide with SEPURAN membranes for gas separation

Since its SEPURAN product launch in 2011, Evonik has delivered gas separation membranes in more than 1,000 reference plants worldwide as of year end of 2021. Evonik reports it is experiencing continued strong demand in biogas, nitrogen, hydrogen and natural gas applications. The expansion of existing production capacities at the Austrian site in Schörfling am Attersee is progressing.

“Having developed and established the biogas industry in close cooperation with our partners, we are establishing now our SEPURAN® membranes in demanding nitrogen, hydrogen and natural gas applications,” said Dr. Iordanis Savvopoulos, head of the Fibres, Foams and Membranes product line at Evonik. “We celebrated the 500th biogas reference plant just under a year ago, and now the next market success for the entire membrane portfolio is hitting us, giving us an important boost for further growth. The market is convinced of our innovative membrane technology.”

SEPURAN membranes make it possible to separate gases, such as methane (CH4), nitrogen (N2), or hydrogen (H2) from gas mixtures. The advantages of Evonik’s membrane technology are more precise separation of the gases and higher productivity. SEPURAN N2 membranes for efficient nitrogen generation are used, for example, to inert aircraft tanks. SEPURAN Noble membranes extract hydrogen transported through natural gas pipelines selectively from the CH4/H2 gas mixture at the delivery points. SEPURAN NG membranes enable efficient natural gas processing from gas sources with high CO2 concentration.

Evonik launched its first membrane product—SEPURAN Green, for efficient upgrading of biogas—on the market in 2011, laying the foundations for future business in membranes. This was followed by further membrane products for nitrogen, helium, hydrogen, natural gas, and nanofiltration applications. The membranes, which are now being successfully used in more than 1,000 system installations worldwide, are produced at Evonik’s site in Schörfling, Austria. The high-performance polymer-based material is produced in neighboring Lenzing.

Source: evonik.com

Fibrix Filtration acquires Americo Manufacturing Co.

Fibrix Filtration, a leading provider of specialized high loft and pleat media air filtration products backed by Branford Castle Partners, LP, a New York City-based private equity firm, announced the acquisition of Americo Manufacturing Company. Americo is a leading producer of floor pads, cleaning accessories, OEM specialty nonwovens and floor matting. The Fibrix Filtration and Americo brands will be held under the newly renamed holding company, Clean Solutions Group (CSG), led by Keith White as president and chief executive officer.

“The transition to a greener and cleaner environment is a monumental challenge for this generation,” said Mr. White. “The combination of Fibrix Filtration’s and Americo’s people, technologies, and assets creates a formidable nonwovens manufacturing platform focused on innovative clean solutions for home and work environments using environmentally sustainable practices.”

“We are enthusiastic to be joining Clean Solutions Group as we continue growing our business by delivering innovative, environmentally friendly products with an unparalleled customer experience,” said Lenny Shutzberg, Americo’s CEO. “The combination of these two great companies makes us stronger, more adaptable and better positioned to leverage our resources for sustainable, future growth.”

Akerman provided legal advisory services and Byline Bank and Brookside Capital Partners provided financing for this transaction. Terms of the deal were not disclosed.

Source: fibrix.com

Xylem reports fourth quarter and full-year 2021 earnings, showing some decreases amid challenging market conditions

Water technology leader Xylem Inc. reported fourth quarter revenue of $1.32 billion, and full-year 2021 revenue of $5.20 billion, in line with previous guidance.

Fourth quarter adjusted earnings before interest, tax, depreciation and amortization (EBITDA) margin decreased 260 basis points to 16.2%. Inflation and strategic investments drove the margin decline, exceeding the benefits of price realization and productivity savings. Xylem generated net income of $113 million, or $0.62 per share, and adjusted net income of $115 million, or $0.63 per share, which excludes the impact of restructuring, realignment and special charges.

For the full year, Xylem delivered adjusted EBITDA margin of 17.1%, up 80 basis points year-over-year. Productivity and volume drove the increase, exceeding inflation impacts. Full-year reported net income was $427 million, or $2.35 per share, and adjusted net income, which excludes the impact of restructuring, realignment and special charges, was $452 million, or $2.49 per share. The Company generated $538 million of operating cash flow, representing a 126% conversion, and $330 million of free cash flow, representing a 77% conversion.

Full-year 2022 outlook

Xylem forecasts full-year 2022 revenue in the range of $5.25 to $5.35 billion, up 1% to 3% on a reported basis and up 3% to 5% on an organic basis. Full-year 2022 adjusted EBITDA margin is expected to be in the range of 16% to 17%. This results in adjusted earnings per share of $2.35 to $2.70, which represents a decline of 6% to an increase of 8% from Xylem’s 2021 adjusted results.

Fourth quarter segment results

Water infrastructure

Xylem’s Water Infrastructure segment consists of its portfolio of businesses serving clean water delivery, wastewater transport and treatment, and dewatering.

- Fourth quarter 2021 revenue was $622 million, a 2% increase compared with fourth quarter 2020. This result was driven by healthy growth in the industrial end market, particularly in the emerging markets, partially offset by delayed revenue conversion in the U.S. utilities market primarily due to extended lead-times for ocean transit.

- Fourth quarter adjusted EBITDA margin was 21.7%, down 50 basis points from the prior year. Reported operating income for the segment was $122 million.

Applied water

Xylem’s Applied Water segment consists of its portfolio of businesses in residential and commercial building services, and industrial applications.

- Fourth quarter 2021 Applied Water revenue was $406 million, a 3% increase organically year-over-year. Industrial end-market strength in Emerging Markets, U.S. and Western Europe was partially offset by weakness in the residential market in China, particularly in light of strong prior-year performance.

- Fourth quarter adjusted EBITDA margin was 13.8%, down 340 basis points from the prior year. Reported operating income for the segment was $50 million and adjusted operating income, which excludes $2 million of restructuring and realignment costs, was $52 million, a 16% decrease versus the comparable period last year.

Measurement & control solutions

Xylem’s Measurement & Control Solutions segment consists of its portfolio of businesses in smart metering, network technologies, advanced infrastructure analytics and analytic instrumentation.

- Fourth quarter 2021 Measurement & Control Solutions revenue was $295 million, down 17% organically versus the prior year. The decline is in-line with expectations and a result of the ongoing chip supply shortage and the outsized impact to our North American smart metering business.

Supplemental information on Xylem’s fourth quarter 2021 earnings and reconciliations for certain non-GAAP items is posted at www.xylem.com/investors.

Source: xylem.com

ASHRAE announces nominees for 2022-23 slate of officers and directors

Nominations for officers and directors were made by the ASHRAE Nominating Committee from a list recommended by individual members and from Chapters Regional Conferences.

The 2022-23 nominees are:

- President-Elect: Ginger Scoggins

- Treasurer: Dennis Knight

- Vice Presidents: Billy Austin, Dunstan Macauley, Sarah Maston, Ashish Rakheja

- Directors and Regional Chairs: Bryan Holcomb (Region IV ), James Arnold (Region V), Susanna Hanson (Region VI), John Constantinide (Region XII), Cheng Wee Leong (Region XIII)

- Directors-at-Large: Blake Ellis, Luke Leung, Wei Sun

- Alternate Director-at-Large: Patrick Marks

ASHRAE members will vote on the nominees via electronic ballot in May. Farooq Mehboob will serve as ASHRAE president for the 2022-23 Society Year.

Source: ashrae.org

Mann+Hummel acquires 100% interest in Pamlico Air

Mann+Hummel, a global filtration solutions provider, announced the close of an agreement to acquire the remaining shares of Pamlico Air, resulting in 100% ownership of the company. Since March 2021, Mann+Hummel has been holding a majority share in Pamlico Air, a U.S. manufacturer and provider of high-quality indoor air filtration products for mainly the retail and wholesale market. The acquisition complements the existing portfolio of Mann+Hummel’s subsidiaries Tri-Dim and Tri-Dim Hardy, which focus primarily on the commercial and industrial indoor air filtration aftermarket. Together, the three North American brands will form the Air Filtration Americas division for the Life Sciences & Environment segment of Mann+Hummel.

“With the vision to enable cleaner mobility, air, and water, MANN+HUMMEL has been actively expanding through both, acquisitions and organic growth, in the air filtration market,” said Fua Nipah, president & general manager Life Sciences & Environment for Mann+Hummel. “With the acquisition of Tri-Dim in 2018, Hardy Filtration in 2019, and now with the full acquisition of Pamlico Air in 2022, we have essentially created a North American powerhouse in air filtration, covering retail, wholesale and commercial aftermarket in the region.

Harry Smith, former Pamlico Air CEO, will continue as executive director to guide the business, specifically managing the company’s growth in the retail sector. Shawn Windley, an industry veteran of over 25 years, will lead the group as president, Mann+Hummel Air Filtration Americas.

Source: mann-hummel.com

Alfa Laval to supply membrane systems to extract dietary fiber from food processes at Denmark food facility

Alfa Laval will supply membrane systems to a food facility in Denmark to produce healthy dietary fiber from crop leftovers. The membranes will extract fibers from sources such as brewers’ grains, corn stover and wheat straw, improving the circularity of the food chain.

The Alfa Laval membrane filtration systems will be used to recover and purify crop leftovers, mainly supplied from local farmers, and process it into prebiotic dietary fiber. These prebiotic fibers are not digestible by the human body, but help ensure healthy bacteria growth in the stomach, which can help with various digestive problems and boost the immune system.

“This is an interesting order in a new and promising application for our membrane systems improving the circularity of the food chain,” says Nish Patel, president of Alfa Laval’s Food & Water Division. “Our efficient membranes will be able to extract valuable fibers and thereby turn former waste into sellable ingredients, which will benefit both our customer and the environment.”

Source: alfalaval.com