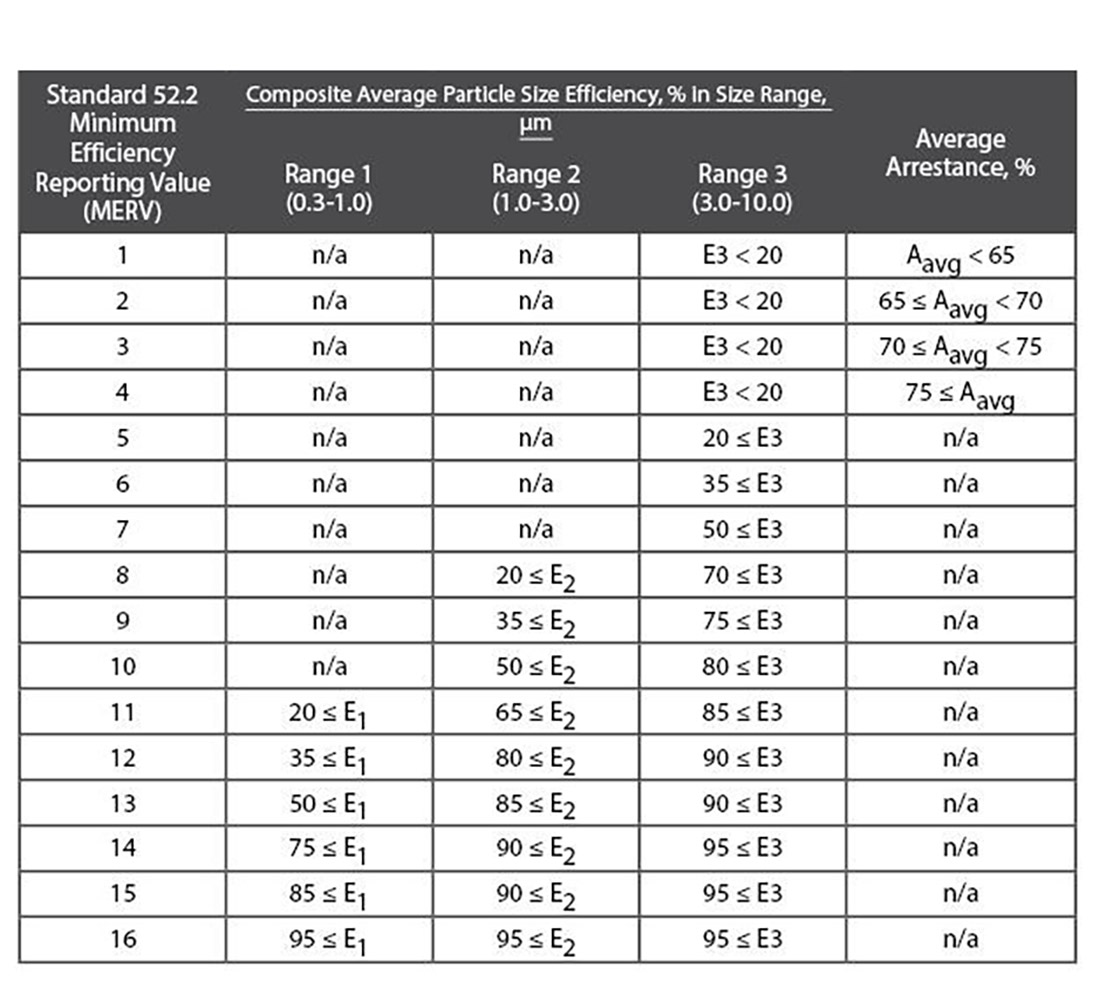

The MERV rating system extends from 1 to 16, with the highest (16) being the rating used for filters in places such as hospitals where it is critical to efficiently capture very small particles. A filter receives a specific MERV rating based on a 1999 specification brought forth by the American Society of Heating, Refrigeration, and Air-Conditioning Engineers (ASHRAE). The higher the MERV rating, the better the filter is at trapping a specific range of particles.

Why MERV-13?

During the COVID-19 pandemic, MERV-13 air filters have gained prominence as the standard minimum filtration in a building, and some states have mandated this level of filtration in their codes. For example, California’s Title 24 code changed from a minimum MERV 8 to a MERV 13 in office buildings, high-rise residential and hotels.

The MERV rating system identifies filtration efficiency of particles that vary in size from 0.3 microns to 10 microns. Therefore, filters that are upwards of 13 in their MERV rating can filter particles closer to the 0.3-micron size at a higher efficacy. This is important from an indoor air quality (IAQ) perspective, as there are different types of particles that can contaminate the air. A MERV-13 filter can filter out what lower-rated filters cannot, such as, for example, bacteria, viruses, and microscopic allergens. ASHRAE and the U.S. Centers for Disease Control recommend a minimum MERV filter rating of MERV-13, but many building owners are considering MERV-14 or better.

Over the past few years, building industry designers and engineers have viewed MERV-13, with an efficiency of 90 percent, as the base filter rating type for new construction. When MERV-13 is paired with carbon filters, the combination is highly effective in eliminating odor and filtering out ultrafine particulate and gaseous molecules, such as those created from smoke and combustion.

MERV-13 in residential applications

MERV 13 filters can stretch the boundary of residential HVAC systems. Any air filter with a rating higher than 13 will restrict air flow to a point that could cause damage to the HVAC system, resulting in an added expense to fix it. So, while the MERV rating does go above 13, and indoor air quality is very important, it is advised to stay away from anything higher than MERV-13 in a typical residential HVAC system.

Understanding the potential impact of implementing MERV-13 filtration into an existing HVAC system is essential. Introducing higher-resistance filters impacts airflow, directly affecting the balance and movement of the air throughout the HVAC ductwork. Knowing the potential pressure drops associated with MERV-13 filters is needed to implement controls, to account for the air resistance, and to prepare the HVAC system for the change. It is best for the average person to employ an indoor air quality specialist to determine the right solution for the HVAC system in question.

Other strategies for MERV-13 in a residential setting

There are many other strategies to consider helping to ensure that a given living or working space has high quality air filtration if the HVAC system won’t support MERV-13 filtration. Using portable air cleaners to supplement increased HVAC system ventilation and filtration is a great strategy, especially in areas where adequate ventilation is difficult to achieve. Increasing air flow by opening dampers, if available, and increasing air changeouts via outdoor air verses recirculated air is also a good strategy.

Air cleaning may be useful when used along with source control and ventilation, but it is not a substitute for either method. Source control involves removing or decreasing pollutants such as smoke, formaldehyde, or particles with viruses. The use of air cleaners alone cannot ensure adequate air quality, particularly where significant pollutant sources are present, and ventilation is insufficient. See ASHRAE and CDC guidelines for more information on air cleaning and filtration and other important engineering controls.

Design considerations for MERV-13

From a system design perspective, upgrading to MERV 13 filters may be a challenge not only for the system, but from a basic fit standpoint. Many residential HVAC systems are engineered to accept 1” filters. This limits the size of filters that can be utilized. A simple strategy to provide a lower pressure drop in a system is to increase the filter size from 1” to 4” and utilize pleated filters. This increases the surface area of the filter while helping to maintain adequate flow rates in the system. However, it also means that many HVAC systems cannot fit higher-rated filters.

The new norm

Despite some of the challenges noted here, I do see MERV 13 filtration as the standard and norm for residential and commercial settings. California has laws dictating MERV-13 usage, as noted earlier, and OSHA has dictated that healthcare facilities meet COVID-19 protocol requirement in 1910.502(k)(iii): “All air filters are rated Minimum Efficiency Reporting Value (MERV) 13 or higher, if compatible with the HVAC system(s). If MERV-13 or higher filters are not compatible with the HVAC system(s), employers must use filters with the highest compatible filtering efficiency for the HVAC system(s).”

Increasingly strict standards and regulations will likely drive the move to MERV-13, and the technology will have to follow.

Parting thoughts

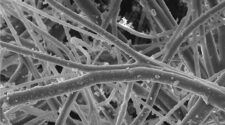

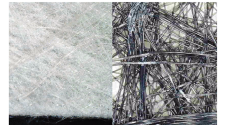

Mechanical upgrades from filter bay sizes and fan augmentation will go a long way in accommodating higher-rated filters. All things equal, it will take more energy to implement as-is. MERV-13 filter media with lower resistance will also play a significant role when reengineering of the system is too costly, and this will help to offset energy cost. New materials are what is needed to make this change more palatable. Lastly, implementing pressure drop systems to monitor the system will provide the necessary notice when a filter needs to be changed, which will protect the system as well.

As director of education and technical affairs, Chris presents regular training related to nonwovens and filter media from INDA’s headquarters in Cary, NC. For more information about upcoming training opportunities, visit inda.org/education.

International Filtration News is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).