In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Matt Migliore at mmigliore@inda.media.

Most recent update: February 26, 2021

Donaldson reports Q2 earnings – Engine Products up, Industrial Products down

Donaldson Company, Inc. reported second quarter 2021 net earnings of $56.2 million compared with $64.4 million in 2020. The current period included charges of $14.8 million related to restructuring activities initiated in the second quarter, primarily in Donaldson’s Europe, Middle East and Africa (EMEA) region. Adjusted net earnings were $66.8 million. Generally Accepted Accounting Principles (GAAP) earnings per share (EPS) for the second quarter 2021 were $0.44 and were $0.50 in 2020. Excluding the impact of restructuring expense, second quarter 2021 adjusted EPS were $0.52.

“Our second quarter results demonstrate the advantage of our diversified portfolio of businesses that allow Donaldson to benefit from cyclical end-market recovery while mitigating the effects of weaker markets at different points in the cycle,” said Tod Carpenter, chairman, president and chief executive officer. “We are executing our strategy to expand our total addressable markets to further enable Donaldson to leverage our filtration technology leadership position, and we are well-positioned to benefit from the post-pandemic recovery.

“We are encouraged by the robust growth in our Engine Off-Road and Aftermarket businesses, which contributed to stronger-than-expected second quarter sales, as well as emerging signs of broad-based recovery. As we are now midway through our fiscal year, and with the backdrop of improving end markets, while noting that uncertainties due to the pandemic continue to exist, full year guidance has been provided for fiscal 2021. We expect adjusted operating margin to increase in fiscal 2021 driven by expanded leverage on higher volumes partially offset by higher commodity costs and mix pressures. I am proud of the hard work and dedication our employees have shown during this unprecedented time of uncertainty. We remain committed to our customers as we advance filtration for a cleaner world.”

Second quarter 2021 Engine Products (Engine) sales increased 6.2%, reflecting strong results in Off-Road and Aftermarket, partially offset by continued weakness in Aerospace and Defense and On-Road. The decline in Aerospace and Defense was primarily due to lower levels of demand in commercial aerospace as a result of the ongoing COVID-19 pandemic. Engine segment sales across the Asia Pacific region experienced year-over-year growth where both Off-Road and Aftermarket sales were up significantly. On-Road sales declined modestly driven primarily by weaker U.S. Class 8 truck builds.

Second quarter 2021 Industrial Products (Industrial) sales declined 4.3%, driven primarily by continued softness in Industrial Filtration Solutions (IFS) due to lower demand for dust collection products as customers remain cautious in making capital investments. China continues to be a positive for IFS as market share gains, coupled with recovery from the COVID-19 pandemic, drove double-digit growth in the country. Process Filtration sales expanded globally driven by market share gains. Gas Turbine Systems’ sales decline was due to lower project sales, and sales in Special Applications remain under pressure from lower sales of disk drive filters.

Source: donaldson.com

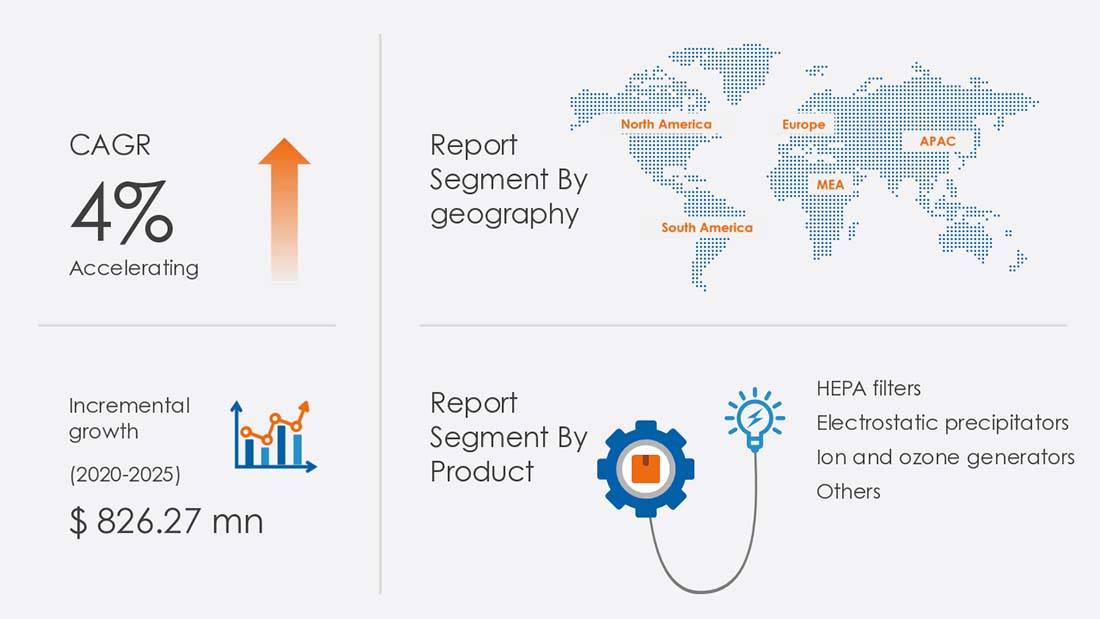

Report predicts global industrial air cleaner market to grow by $826.27 million 2020-2025

A research report by Technavio says the global industrial air cleaner will grow by USD $826.27 million from 2020-2025, accelerating at a CAGR of over 4% during the forecast period. The growth trajectory of the market is traced through a detailed analysis of the prevalent market forces, trends, and drivers along with competitive benchmarking.

The market is segmented by product into HEPA filters, electrostatic precipitators, ion and ozone generators, and others. The HEPA filters segment is the more popular market segment. Factors such as recovery in automotive industry and the development of next-generation engines, growing emissions owing to increasing economic activities, and stringent norms and regulations on emissions will offer immense growth opportunities. This report provides an accurate prediction of the contribution of all the segments to the growth of the industrial air cleaners market size.

Asia Pacific (APAC) was the largest Industrial Air Cleaners Market in 2020, and the region will offer several growth opportunities to market vendors during the forecast period. 55% of the market growth will originate from APAC during the forecast period. China, Japan, and India are the key markets for industrial air cleaners in APAC. This report provides an accurate prediction of the contribution of all segments to the growth of the industrial air cleaners market size.

The market is concentrated. The growth of the players depends on several factors such as market conditions, government support, and industry development. To survive and succeed in such an intensely competitive market, players must distinguish their product and service offerings through clear and unique value propositions. 3M Co., Alfa Laval AB and Camfil AB are some of the major market participants. To make the most of the opportunities, market vendors should focus more on the growth prospects in the fast-growing segments, while maintaining their position in the slow-growing segments, according to Technavio.

Source: technavio.com

Veolia Water Technologies to supply systems for reuse of 40,000 m3 of water per day in Kuwait

Veolia Water Technologies Gulf was awarded a contract by Mohammed Abdulmohsin Al-Kharafi & Sons (Al-Kharafi) to supply, supervise, install and commission 53 AnoxKaldnes Moving Bed Biofilm Reactor (MBBR) packaged sewage treatment plants. This order is the largest ever received by Veolia for this type of packaged plants and will allow for 40,000 m3 of water to be reused each day in water-scarce Kuwait.

The compact and packaged sewage treatment units will be installed at various locations throughout the country where they will compensate a shortage in sewage handling. A major advantage of these smaller, packaged units when compared to one big wastewater treatment plant is that the size of the network is vastly reduced as it is possible to spread the units in various parts of the housing development or city.

Following treatment, the effluents will be reused for irrigation, therefore saving freshwater that would otherwise have been desalinated at high cost, particularly in terms of energy.

In Sabah Al Ahmad City, a planned community located 80 kilometres south of Kuwait City in Khiran Kuwait, 23 AnoxKaldnes MBBR package plants with a total treatment capacity of 17,000 m3/day will be added to existing sewage treatment installations. In West Abdullah City, new sewage treatment installations will be built and will include 27 package plants totalling 23,000 m3/day. Finally, three more units will be installed as provisional items at other locations.

Veolia Water Technologies will also supply pretreatment and UV disinfection as well as proprietary Veolia technologies Multiflo for clarification and Hydrotech Drumfilters for tertiary treatment. Veolia’s digital solution Hubgrade will also be provided to support the operational teams in their daily monitoring with a proactive, data-driven service and remote reporting.

Source: veoliawatertechnologies.com

Grolsch running pilot with NX Filtration nanofiltration technology at its brewery in Enschede, Netherlands

The renowned Grolsch brewery in Enschede, the Netherlands, has partnered with NX Filtration, a membrane manufacturer also headquartered in Enschede, to launch a full-scale water treatment pilot. With the results from this pilot Grolsch will compare NX’s dNF membrane technology with conventional water treatment solutions on important factors such as the retention of micropollutants and hardness, energy usage and the need for cleaning agents.

Grolsch has a long history of improving reliability and robustness of its processes and minimizing impact on the environment. At its location in the eastern part of the Netherlands, where summer droughts have become longer and more severe over the years, ground water levels are declining. To assure that, despite these regional challenges, the well water that is used for brewing its beer will remain at the highest standards, Grolsch is now investigating NX Filtration nanofiltration membranes as a more sustainable option to its current treatment methods.

Source: nxfiltration.com

TTG announces Kyle Nannenga will join ePTFE membrane business with a focus on air filtration

TTG (Trinity Technology Group), a leader in ePTFE technology for the industrial, apparel, microventing, and medical markets, announce that Kyle Nannenga has joined the company to expand sales efforts primarily in the air filtration market. A strategically critical sector for the application of TTG’s proprietary ePTFE membrane and laminate technologies, Nannenga’s extensive commercial expertise in the air filtration category will provide additional value to TTG’s current customer base and help expand TTG’s footprint in the filtration market.

“Filtration is a core legacy market for our company and bringing Kyle on board is a continued demonstration of our commitment to this sector of our business,” said Greg Vas Nunes, TTG’s CEO. “Kyle’s substantial experience and industry know-how will help us grow the air pollution control and related filtration categories with new products, technologies, and applications and will also further enhance our unique collaborative approach to providing outstanding customer service.”

Nannenga will join TTG as sales executive, bringing to the job his fourteen years of filtration sales experience with Donaldson Company where he rose to the level of sales director. In that position, he led the commercial OEM channel of the Industrial Air Filtration Business Unit throughout North America and developed deep expertise in filtration media, substrates, and ePTFE membrane applications that he will leverage for the TTG business. Nannenga held analyst positions with Target Corporation and the U.S. Department of Veterans Affairs earlier in his business career. Prior to joining the private sector, Nannenga served as a combat engineer in the United States Army/National Guard and is a decorated veteran of Operation Iraqi Freedom.

Source: ttgtech.net

Report predicts North American virus filtration market will grow 11.86% per year through 2026

The North America virus filtration market is expected to grow by 11.86% annually in the forecast period and reach $2,554.1 million by 2026, owing to rapid growth of pharmaceutical and biotechnology industry, increasing investments in R&D, surging need for virus removal and clearance amid COVID-19 pandemic. according to a new report by ResearchAndMarkets.com.

The report is based on a holistic research of the entire North America virus filtration market and all its sub-segments through extensively detailed classifications. The report is based on studies of 2016-2019 and provides forecast from 2020 till 2026 with 2019 as the base year.

Specifically, potential risks associated with investing in North America virus filtration market are assayed quantitatively and qualitatively through a Risk Assessment System. According to the risk analysis and evaluation, Critical Success Factors (CSFs) are generated as a guidance to help investors & stockholders identify emerging opportunities, manage and minimize the risks, develop appropriate business models, and make wise strategies and decisions.

Source: researchandmarkets.com

INDA adds webinar program to discuss new ASTM facemask standard for the general public

INDA, the Association of the Nonwoven Fabrics Industry, has added a date to its upcoming webinar series, Tuesday, March 2, 11 am EST, to discuss the new ASTM F3502-21 Standard Specification for Barrier Face Coverings, which was introduced by ASTM on February 15. This standard establishes a set of test methods that evaluate the filter, fit and leakage performance of barrier face coverings, commonly referred to as “facemasks,” worn by the general public and not to be confused with respirators nor medical or surgical masks. The webinar will be presented by respiratory expert, Jeff Stull, Vice Chair of the ASTM Committee that wrote the standard, and Dave Rousse, INDA President. It will provide a detailed review of the new ASTM standard and the test methods it entails and the impact on the entire supply chain of facemask production.

The purpose of guidance for the general public to wear facemasks is to control the spread of viruses. Facemasks made to this new ASTM standard will also provide a degree of particulate filtration to reduce the amount of inhaled particulate matter.

“We approached NIOSH last year on developing a general public facemask standard that could use nonwoven materials beyond Meltblown that still deliver an effective level of filtration, as there was so much demand for the N95 respirators and masks once the Asian supply chain was cut off,” said Dave Rousse, INDA President. “We were delighted to get a positive response from Jon Szalajda, NIOSH Deputy Director, National Personal Protective Technology Laboratory, who is also the Chair of the ASTM Committee dealing with standards in this area.”

“This was a worthwhile project that we worked through the ASTM process in record time,” said Szalajda. “It should provide an important benefit in the fight against COVID-19 spread by reducing consumer confusion about what works and what does not and assisting manufacturers in making effective products.”

The goal of the standard is to assist consumers in making informed decisions about facemasks given the vast array of products currently for sale, including various patterns promoted for home-made manufacture using common textile materials. Prior to the ASTM standard, no standard test method existed which allowed comparisons among different products nor were there any minimum performance requirements. This new standard provides these performance requirements as well as a set of specifications, guidelines and expectations for facemask manufacturers and media suppliers.

The Mar. 2 webinar will be in addition to the INDA Webinar Series already scheduled for March 16, March 25 and April 6. For information on the full webinar series, visit www.inda.org/inda-webinars.

Source: inda.org

* International Filtration News is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).

Research shows sorry state of air quality in U.S. subway systems

As reported by The Guardian, People traveling on subway systems in major U.S. cities are being exposed to unsafe amounts of air pollution, with commuters in New York and New Jersey subjected to the highest levels of pollution, research has found.

Tiny airborne particles, probably thrown up by train brakes or the friction between train wheels and rails, are rife in the 71 underground stations sampled by researchers during morning and evening rush hours in Boston, New York City, Philadelphia and Washington DC, the cities that contain the bulk of subway systems in the US.

The levels of these tiny specks of pollution, called PM2.5, were well above nationally determined safe daily levels of 35 micrograms per cubic meter in each of the cities. New York’s Metropolitan Transit Authority (MTA) system had 251 micrograms per cubic meter, followed by Washington DC with 145 micrograms per cubic meter. Philadelphia was, comparatively, the cleanest system but still breached the limit beyond which serious health hazards are risked.

Read the full story: https://www.theguardian.com/environment/2021/feb/10/subway-air-pollution-new-york-washington-dc

Source: theguardian.com

NX Filtration supplies its nanofiltration membranes to Forsmark power plant in Sweden

For the local production of drinking and process water for the Forsmark power plant in Sweden, ProMinent, a multinational water treatment systems supplier, installed a water treatment system based on hollow fiber nanofiltration membranes of NX Filtration.

The feed water is taken from a local, highly colored lake with temperatures close to zero degrees Celsius in the winter. This feed water goes through a simple one step process consisting of, initially, 74 dNF40 hollow fiber nanofiltration modules of NX Filtration. This system removes bacteria, viruses and organics, including color, from the lake water. The resulting product water is used for drinking water and for process water in the Forsmark power plant.

Compared to the existing system, which is based on coagulant injection, dissolved air flotation and sand filtration, the new nanofiltration setup offers various benefits, such as better removal of organics, micropollutants and other contaminations. It also avoids the use of chemicals in pretreatment and it reduces the number of process steps, which also results in a smaller physical footprint of the system.

Source: nxfiltration.com

Metso Outotec to reorganize its Sweden operations

Metso Outotec, a combination of Metso Minerals and Outotec on June 30, 2020, specializing in end-to-end solutions and services for the minerals processing, aggregates and metals refining industries globally, has convened local trade unions to negotiations concerning the restructuring and operational reduction of its operations in Sweden. The measures relate to new product strategy and business model changes and synergy targets from the Metso Outotec merger.

The Swedish operations have issued a negotiation proposal, according to which the total reduction need in Sweden is approximately 80 white collar positions mainly in the Minerals, Metals and Services business areas in the Skellefteå and Sala locations. Other locations may be impacted to a small extent.

Source: mogroup.com

Oerlikon Nonwoven, Wolf PVG commission meltblown plant for FFP2 masks

Oerlikon Nonwoven has commissioned a double-beam meltblown plant with ecuTEC+ electro charging unit at Wolf PVG GmbH & Co. KG. With this plant, the East Westphalian company can now provide nonwovens for the production of surgical and FFP2 masks. In addition to this filter material, which is in great demand today, high-quality meltblown nonwovens can also be produced for medical and industrial filter applications. The plant has now been running for several weeks under stable production conditions with optimal nonwoven fabric quality of the highest standards.

With the beginning of the COVID-19 pandemic and the shortage of protective masks that ensued, Wolf PVG GmbH & Co. KG, a wholly owned subsidiary of the Melitta Group, switched part of its production capacities to nonwoven mask fabric production. As a highly specialized system supplier for everything to do with vacuum cleaners and industrial filter technology, the company from East Westphalia can fall back on its extensive know-how and many years of experience.

With the meltblown plant from Oerlikon Nonwoven, Wolf PVG is further expanding its production capacities. The plant, with its two beams and the ecuTEC+ electro charging unit, is optimally designed for the production of face mask material. The plant is also ideal for the production of other filtration nonwovens. “A decisive point for investing in a plant from Oerlikon Nonwoven was the flexibility of the plant in relation to the possible product portfolio and the competence of the manufacturer,” said Markus Seele, COO of Wolf PVG. Dr. Ingo Mählmann, senior vice president of Sales & Marketing for Oerlikon Nonwoven, said, “Thanks to the numerous setting options for the electrostatic charge provided by the ecuTEC+, the optimum loading status can be set depending on the filter application.”

Source: oerlikon.com

Porex wins 3M Supplier of the Year Award

Porex Corporation, a leader in porous polymers, was recognized in the 2020 3M Supplier of the Year Award program in recognition of the company’s contribution to improving 3M’s competitiveness.

This year, 3M recognized 20 suppliers supporting the U.S. and Canada, among thousands in its global supply base, for world-class performance in providing products and services. These suppliers were identified and rated based on actions taken to improve 3M’s competitiveness and overall supplier performance. A virtual awards ceremony was held Feb. 4, 2021.

“We are extremely honored to receive the 3M Supplier of the Year Award from one of our most valued partners,” said Rob Carpio, CEO of Porex. “Through our collaboration, we are helping 3M deliver essential products that make the world safer, healthier and more productive by providing greater comfort and safety to front-line workers who play a critical role in the fight against COVID-19.”

Porex Corporation has been partnering with customers to deliver engineering and design innovations that turn their product ideas into reality. Through a collaborative engineering partnership, Porex develops high-value porous polymer solutions to their product design challenges in absorption, application, diffusion, filtration, reflectivity, venting, and wicking.

Source: porex.com

BHS-Sonthofen merges Filtration Technology division into new Process Technology division

With its acquisition of AVA GmbH & Co. KG in 2018, BHS-Sonthofen expanded its range of solutions and consulting services in and around mixing, drying, granulation, sterilization and reaction. BHS is consolidating its process expertise and portfolio of filtration technology and related products in the newly established BHS-Sonthofen Process Technology GmbH & Co. KG. This marks the final step in the process of integrating AVA into the group.

“We have fully repositioned the company with three business units, Building Materials Machinery, Recycling & Environment, and Process Technology,” says Dennis Kemmann, CEO of BHS-Sonthofen. “Each of the business units serves specific industries. We work in partnership with customers primarily from the chemical and pharmaceutical industries, but also from the food production and other sectors, to develop process technology solutions.”

BHS-Sonthofen Process Technology provides system solutions as well as individual machines and components. The focus is on process engineering consulting for the customer, drawing on the company’s decades of experience acquired in a large number of different projects. One of its core businesses involves testing customer materials. BHS has recently expanded its testing capacity in target markets like the U.S. in an effort to best serve our customers where they are.

Source: bhs-sonthofen.com