A Two-Pronged Filtration Focus for Audi

Car giant Audi, headquartered in Ingolstadt, Germany, and part of the Volkswagen Group, has recently been addressing the problem of emissions generated by both its vehicles in urban areas and in operations at its car manufacturing plants.

In a pilot project with supplier Mann+Hummel, the automaker has developed a filter for electric cars that collects particulate matter from its surrounding area. Both while driving and charging, it’s aim is to help improve air quality in cities.

Regardless of a vehicle’s drive system, 85% of fine dust in road traffic is caused by brake, tire, or road abrasion. The smallest dust particles – hardly noticeable to the naked eye – are only a few micrometers in size with a diameter of only 10 micrometers and can therefore be easily inhaled.

Limits

This year, the World Health Organization (WHO) has recommended significantly lower particulate matter limits than in the past but according to experts, it would be impossible to comply with these new values in many urban areas in Germany.

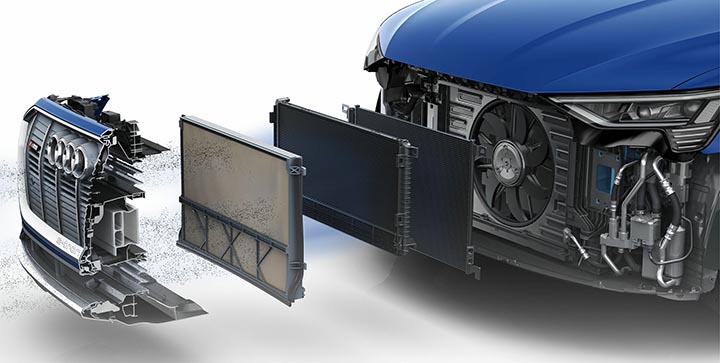

The new filter, designed for the front end of electric vehicles such as the Audi e-tron on which it is being tested, functions in a similar way to the stationary Filter Cube systems that have been developed by Mann+Hummel and are already in use in some German cities. The mobile version ensures not only that the car’s own particulate emissions are absorbed, but that those of other vehicles can be absorbed as well, in the vicinity of where they are generated.

The pilot project was launched in 2020 and will run for a period of four years.

“This particulate filter is an example of our pursuit of innovation for everyone’s benefit and a successful collaboration with specialized suppliers,” said Fabian Groh, project manager of attachment system development at Audi AG. “We are already doing a lot today on our own initiative but anticipate it will also become a legal requirement in the future.”

Airflow

The filter is integrated into the vehicle’s existing airflow in front of the radiator so that only a few modifications to the car are necessary, keeping costs down. The filter element is controlled via the switchable cooling air inlet and its mechanical function is comparable to that of a vacuum cleaner. By a similar principle, the fine dust particles remain stuck in the filter and the air can still flow through it.

In the Audi e-tron vehicles on which it has been tested, the filter has proved effective at passively capturing even the smallest of particles by means of the movement of the vehicle as air flows through the filter system.

Another possibility is filtering during stationary charging. A fan that is already built into every electric vehicle conveys ambient air through the radiator and the system takes advantage of this process and can actively filter the air flowing through it, using the fine dust filter even when stationary.

The assessments conducted on the test vehicles were not only used to analyze the effectiveness of the filters, but also to determine whether the technology affects overall vehicle usage.

The system is so effective that, depending on the usage scenario, the Audi e-tron particles are completely filtered out in a highly polluted city such as Stuttgart.

Endurance Tests

After over 50,000 kilometers of endurance tests on the Audi e-tron, the filters were shown to have no negative effect on the operation of the electric vehicle, including on hot summer days or during fast charging.

The system is so effective that, depending on the usage scenario, the Audi e-tron particles are completely filtered out in a highly polluted city such as Stuttgart. In even more polluted cities, fine dust emissions can be actively and passively absorbed by up to three vehicles in a typical customer scenario.

To make the system even more efficient, Audi is working with Mann+Hummel to connect with existing sensors such as weather stations and also plans to develop a display logic in the vehicle, allowing passengers to determine when the system is active and how much has already been filtered.

The filter is easy to maintain and needs to be replaced only when the regular service interval has been reached. A lifecycle analysis of the entire filter system has shown that it will account for 14.9 kilograms (32.8 lbs.) of CO2 equivalents. Additionally, the filter itself consists of 15% recycled material and the entire system is 60% recycled.

Direct Air Capture

Meanwhile, Audi has also been working with the Linz, Austria-based green tech company Krajete GmbH on the development of new technologies for filtering emissions – initially CO2 – from ambient air in industrial plants.

In addition to robust adsorber materials, the so-called direct air capturing technologies (DACs) are based on new processes that make far-reaching energy and cost reductions possible.

At an Audi plant in Austria, the partners are using an inorganic filter material that can hold a very high load of molecules and is also very insensitive to the effects of moisture.

As a result, it is not necessary, or only necessary in particular cases, to pre-dry the ambient air to be filtered. This increases efficiency and reduces costs. The temperature and pressure conditions for absorbing CO2 molecules and subsequently removing them from the adsorption surface are very similar and this significantly shortens the adsorber’s loading and discharge cycles – more CO2 can be removed from the ambient air in a short period of time.

The filtered air is released back into the environment after the adsorption step and the recovered CO2 is then available in a highly concentrated form as a raw material for permanent storage or for a wide range of industrial applications. The large-scale plant near Linz, which is currently in the process of going into operation, can filter 500 tons of CO2 per year. By the end of the year, another module will increase the plant’s capacity to 1,000 tons. The electricity required to operate the plant comes from a photovoltaic system on the company’s premises.

Efficiency

“We started from the premise that, for reasons of efficiency, we would let the process run at ambient pressure, then we modified the adsorber materials and the physical conditions in the plant until we found the optimal flow rate, meaning we filtered the maximum amount of CO2 per unit of time,” explained Alexander Krajete, CEO of Krajete GmbH. “This made it possible to significantly reduce the cost of sequestration, which is already down to the low three-digits range in Euros per ton of CO2. The long-term goal is to make carbon dioxide usable for industrial purposes. In doing so, Krajete GmbH and AUDI want to facilitate breakthroughs in the necessary applications.

“This technology makes it possible to remove CO2 directly from the atmosphere, regardless of location, and is therefore an important decarbonizing measure,” added Hagen Seifert, head of sustainable product concepts at Audi. “In addition, the system technology can be expanded in a variety of ways thanks to its modular design.”

Larger Scale

As a next step to the existing large-scale plant in Linz, Audi is currently looking into the possibility of using sources with higher concentrations of CO2 and filtering additional emissions such as nitrogen oxides. In addition, DAC technology could be implemented on a much larger scale at Audi’s site in Győr, Hungary. A plant with a capacity of 25,000 tons per year is conceivable.

By 2025, the Volkswagen Group aims to reduce the ecological footprint of its passenger cars and light commercial vehicles by 40% over their entire life cycles, as compared to 2018. Each particular measure is contributing to achieving carbon-neutrality throughout the company, by 2050 at the latest.

![Figure 1: Heat Exchanger Proventics GMBH.[22]](https://www.filtnews.com/wp-content/uploads/IFN_2_2024_crimpedmicrofiberyarns_Fig.-1-Heat-exchanger-225x125.jpg)